Which Rubber Products Are Suitable for Vibratory Bowls?

Core Conclusion: The vast majority of rubber products are unsuitable. Only under very limited and specific conditions might the use of a specially designed vibratory bowl be considered.

Why Rubber Products Are Generally Unsuitable for Vibratory Bowls:

- High Friction & Stickiness: The high-friction surface of rubber causes it to adhere to the metal track of the bowl, preventing part movement and causing pile-ups.

- Prone to Deformation: During vibration, rubber parts easily bend, fold, and tangle together, unable to maintain the stable shape required for separation and orientation.

- Static Electricity: Rubber is an excellent insulator and readily generates and holds a static charge, causing parts to cling to the bowl wall or track cover.

- Light Weight: Many rubber parts are lightweight, and the inertial force generated by vibration may be insufficient to propel them effectively along the track.

Rubber Product Types That Might Be Considered Under Extreme Conditions:

If your rubber product meets ALL of the following stringent criteria, you could attempt to use a specially designed bowl:

- Small, Rigid, Simple-Shaped Rubber Parts

- คำอธิบาย: Made from hard rubber, shaped like washers, simple O-rings (with a thick cross-section), or small plugs—almost behaving more like hard plastic than rubber.

- Reason: They possess sufficient rigidity and weight to resist deformation, and their regular shape facilitates flow.

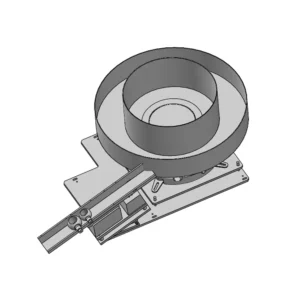

Essential Special Design for Bowls Handling Rubber Products:

- Non-Stick Coating (e.g., Teflon): A low-friction coating for the entire bowl and track is mandatory.

- Air Blow-Off System: Compressed air jets at key track locations are needed to “blow” the parts and help them overcome adhesion.

- Extremely Low Part Level: Strictly control the number of parts in the bowl to minimize contact and pressure between them.

- Optimized Vibration Profile: Use high-frequency, low-amplitude vibration to avoid excessive part bouncing and tumbling.

- Static Eliminator: An ionizing blower is essential to neutralize static charges at the source.

Recommended Alternative Solutions

For feeding rubber products, the following non-vibratory solutions are far superior and more reliable:

- Pusher-Type Feeders

- Principle: A linear pusher gently separates and pushes rubber parts one by one from a magazine.

- ข้อได้เปรียบ: Completely avoids issues related to vibration, friction, and static. This is the primary recommended solution for rubber parts.

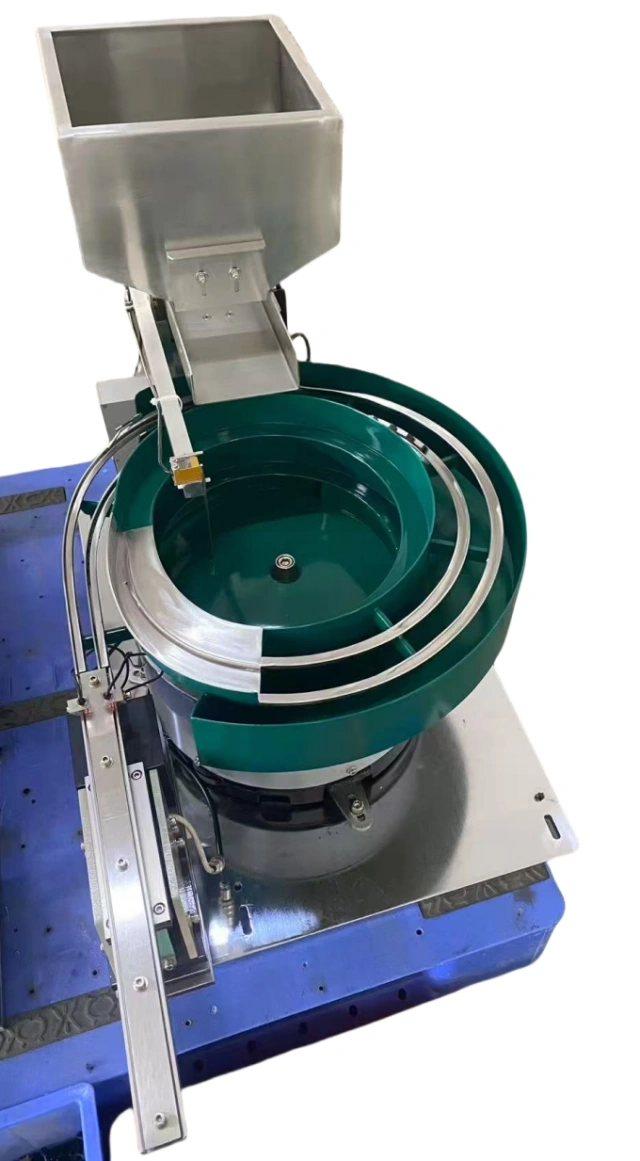

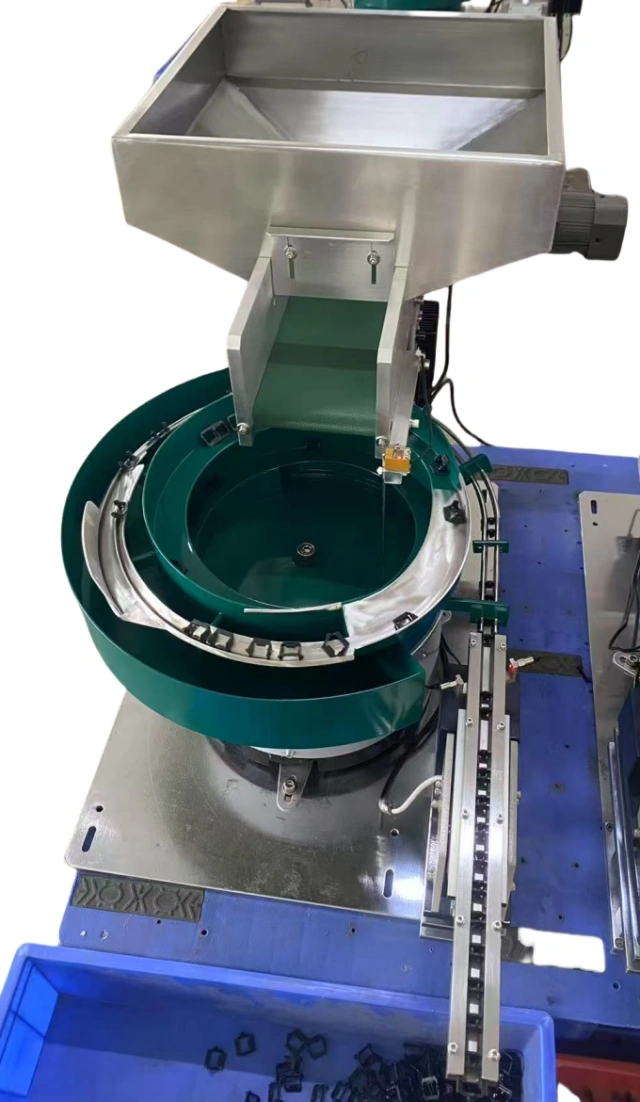

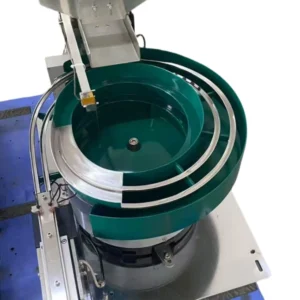

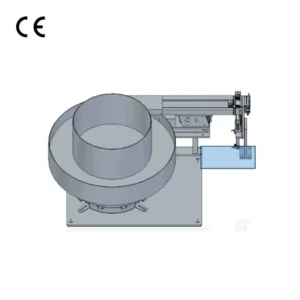

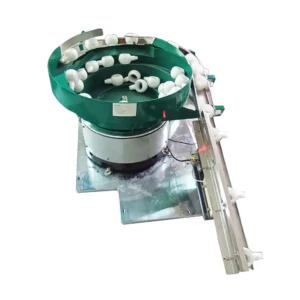

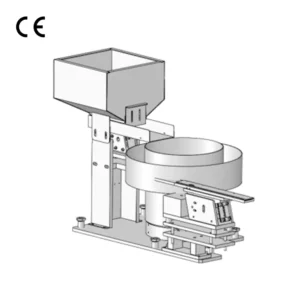

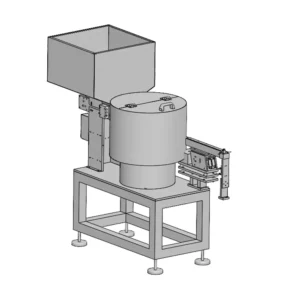

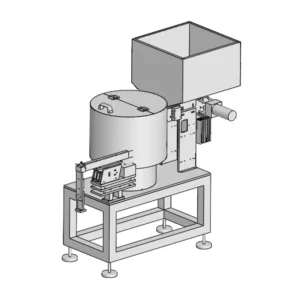

- Centrifugal Feeders (Rotary Hoppers)

- Principle: Uses a slowly rotating disc or flapper arms to pick parts from the bottom of a hopper and gently place them onto a track.

- ข้อได้เปรียบ: The action is gentle and part-friendly, making it very suitable for soft, tangle-prone items.

- Flexible Feeders with Vision Systems

- Principle: A robot scatters a handful of parts onto a platform. A vision system identifies and locates them, guiding the robot for picking.

- ข้อได้เปรียบ: Solves all problems caused by vibration and friction at their root. Ideal for low-volume, high-mix production.

รีวิว

ยังไม่มีบทวิจารณ์