Demand for Vibratory Bowls in Industry

The demand for vibratory bowls in industrial automation can be described as fundamental, widespread, and steadily evolving.

I. Reasons for High Demand

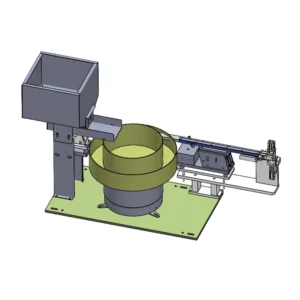

Core Component of Automation: Any industry involving automated assembly, sorting, and feeding of small parts typically requires vibratory bowls. They remain the most classic and cost-effective solution for converting “bulk” into “order.”

Extremely Broad Application: Industries from electronics, automotive, and medical devices to hardware, food packaging, and consumer goods are potential markets.

Hard-to-Replace Advantages: For high-volume feeding of small, uniform parts, vibratory bowls often offer an unbeatable combination of cost, speed, and reliability.

II. Current Demand Trends

Stable Foundation: Continuous automation upgrades in traditional manufacturing provide steady demand.

Shift Towards Premium & Customization: Growing demand for bowls with special materials, lower noise, higher precision, and integrated vision or IoT capabilities.

Integration with New Tech: Increased demand for integrated “Bowl + Robot + Vision” solutions, raising performance requirements for the bowl itself.

III. Factors Influencing Demand

Positive Drivers: Global push for automation, rising labor costs, need for higher efficiency and consistency.

Challenges: Competition from alternatives like flexible feeders in high-mix production; rising customer demand for complete solutions.

In summary, the demand for vibratory bowls is substantial and resilient. It is not disappearing but evolving—transforming from a standard commodity into a critical, often highly customized, automation component.

รีวิว

ยังไม่มีบทวิจารณ์