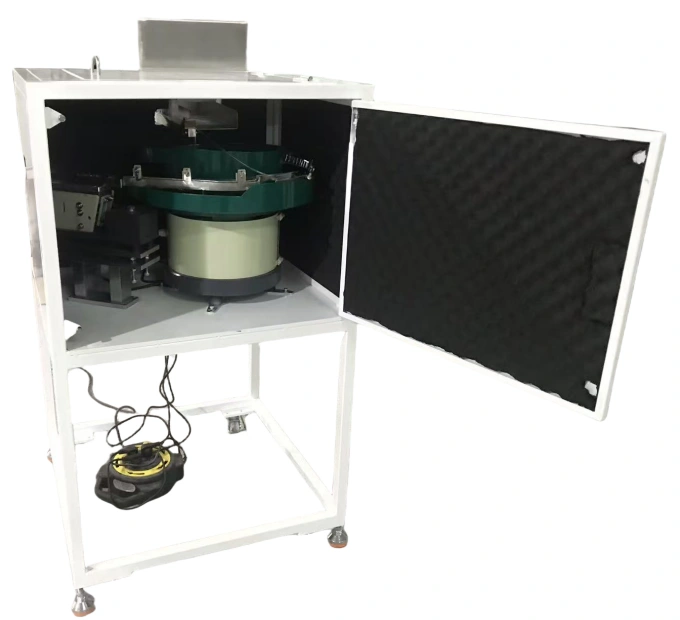

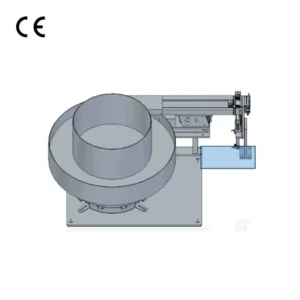

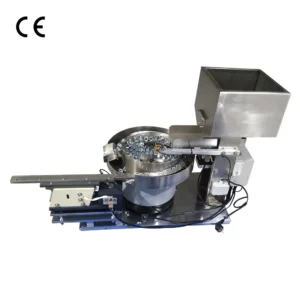

How to Adjust a Vibratory Bowl?

Tuning a bowl involves balancing amplitude และ frequency for optimal part flow. Always disconnect power before initial inspection.

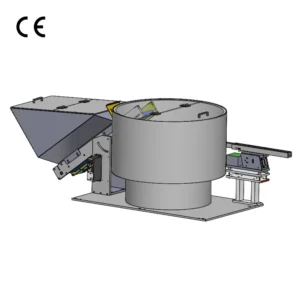

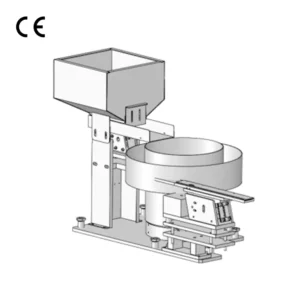

- Preliminary Inspection

- Safety: Ensure power is OFF.

- Check Fasteners: Tighten all bolts.

- Check Air Gap: Ensure the electromagnet gap is clear and within specification.

- Core Adjustment Steps

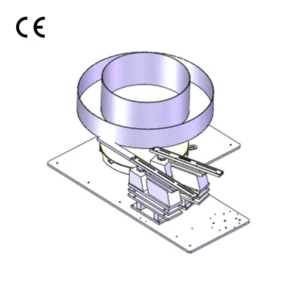

- Adjusting the Leaf Springs

- Goal: Change the vibration angle and force.

- Quantity: Adding springs reduces amplitude (gentler feed); removing springs increases it (more forceful).

- Angle: Fine-tune the spring pack’s attack angle for precise control.

- Adjusting the Controller

- Goal: Change vibration strength and rhythm.

- Amplitude Knob: Adjusts voltage. Clockwise increases amplitude; counterclockwise decreases it.

- Frequency Knob (if available): Adjusts the on/off frequency of the electromagnet.

III. Testing and Optimization

- Load Parts: Add a small sample of parts.

- Power On: Start with low amplitude.

- Observe and Tune:

- If parts don’t move: Slowly increase amplitude.

- If parts bounce or stand up: Decrease amplitude.

- For jams: Inspect and adjust local track tooling or vibration.

- Full Load Test: Gradually increase parts to normal level to ensure stability.

Summary: The golden rule is “start low and adjust incrementally.” Success is achieved when parts flow steadily, continuously, and controllably without bouncing, backflow, or piling up.

รีวิว

ยังไม่มีบทวิจารณ์