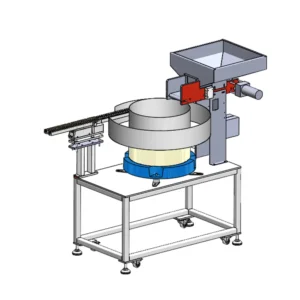

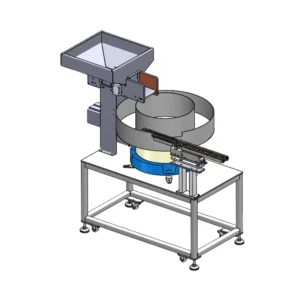

Which Plastic Products Are Suitable for Vibratory Bowls?

In general, plastic products made from rigid engineering plastics, with sturdy structures, resistant to deformation, and low static buildup are more suitable for vibratory bowls.

Highly Suitable Plastic Product Types:

Sturdy Injection-Molded Parts

Examples: Bottle caps, toy bricks (e.g., LEGO), small gears, bearing housings, connector housings, tool handle components.

Reason: These are typically made from rigid plastics like ABS, Nylon (PA), Polycarbonate (PC), POM (Acetal), which have high structural strength and can withstand vibration and impact.

Small Parts with Regular Shapes

Examples: Plastic screws, nuts, washers, plugs, small lids.

Reason: Simple, symmetrical shapes with a clear center of gravity make them easy to orient and separate on the track, ensuring smooth flow.

Medical & Consumer Electronics Components

Examples: Pen caps, sprayer buttons, disposable razor heads, medicine bottle caps, stethoscope earpieces.

Reason: They require high-speed automated assembly and are usually made from sturdy, medical-grade or durable plastics.

Plastic Product Types Requiring Special Design or Potentially Problematic:

Soft/Flexible Plastic Parts

Examples: O-rings, tubing connectors, silicone sleeves, TPU/TPE products.

Reason: The material is too soft, prone to deforming, folding, or adhering to the track during vibration, causing jams.

Thin-Walled and Fragile Parts

Examples: Thin plastic films, brittle plastic shells, delicate snap-fits.

Reason: Vibration and impact can cause them to crack, break, or deform.

Parts with Adhesive Properties

Examples: Stickers with backing, adhesive-backed pads.

Reason: Vibration will cause them to stick to the track or bowl wall, preventing movement.

Parts with Complex Shapes Prone to Interlocking

Examples: Parts with deep holes or internal cavities, long slender plastic parts.

Reason: They can hook into each other or nest (“bird-nesting”) during vibration, making separation difficult.

Key Measures for Successful Use with Vibratory Bowls:

If your plastic product falls into the “highly suitable” category or is borderline, the following measures are crucial:

Surface Treatment: The bowl track often requires a non-stick coating (e.g., Teflon). This significantly reduces friction and static adhesion, protecting the product surface from scratches.

Optimized Vibration: Use lower amplitude and higher frequency vibration settings for gentler, more controlled feeding.

Static Elimination: Install an ionizing blower to neutralize static electricity generated by friction between the plastic and the track, preventing parts from sticking.

Customized Track Design: Use wide tracks, covered tracks, or air blow-offs to prevent parts from standing up, overlapping, or jamming.

รีวิว

ยังไม่มีบทวิจารณ์