Vibratory Parts Feeding Systems Supplier

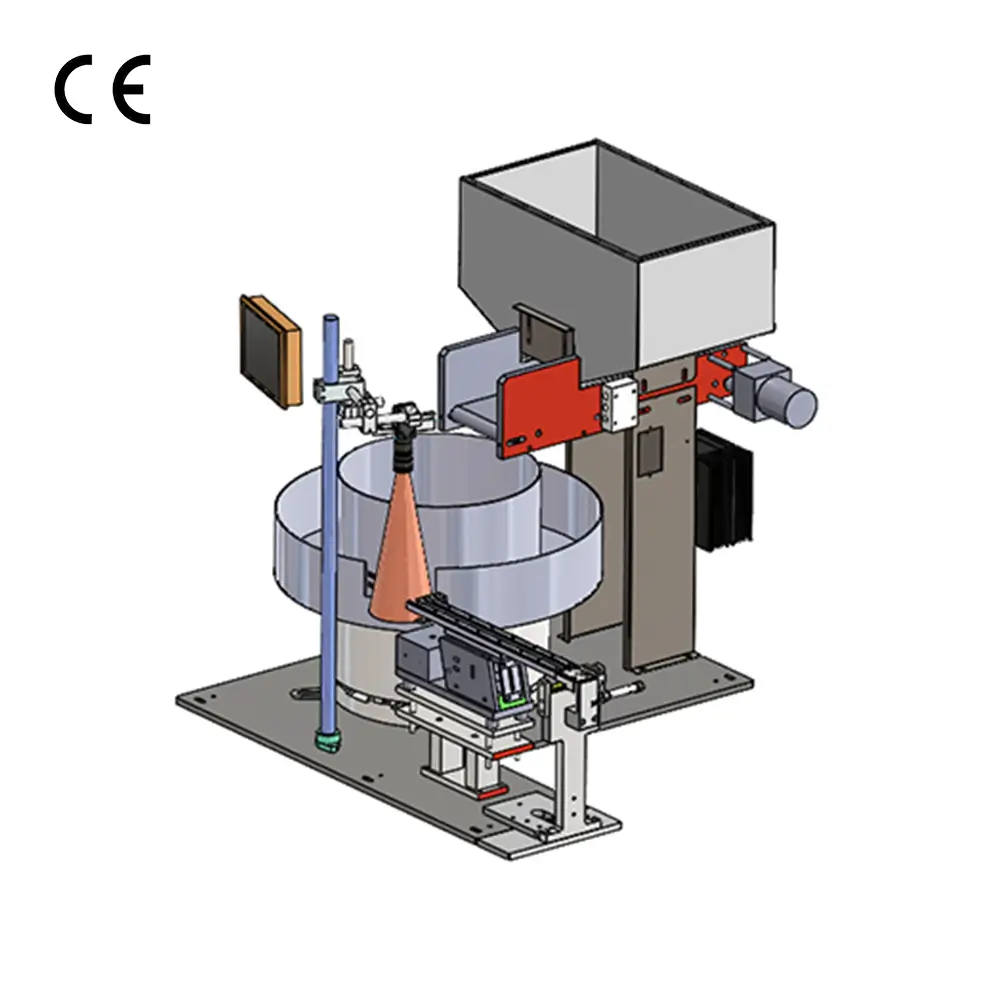

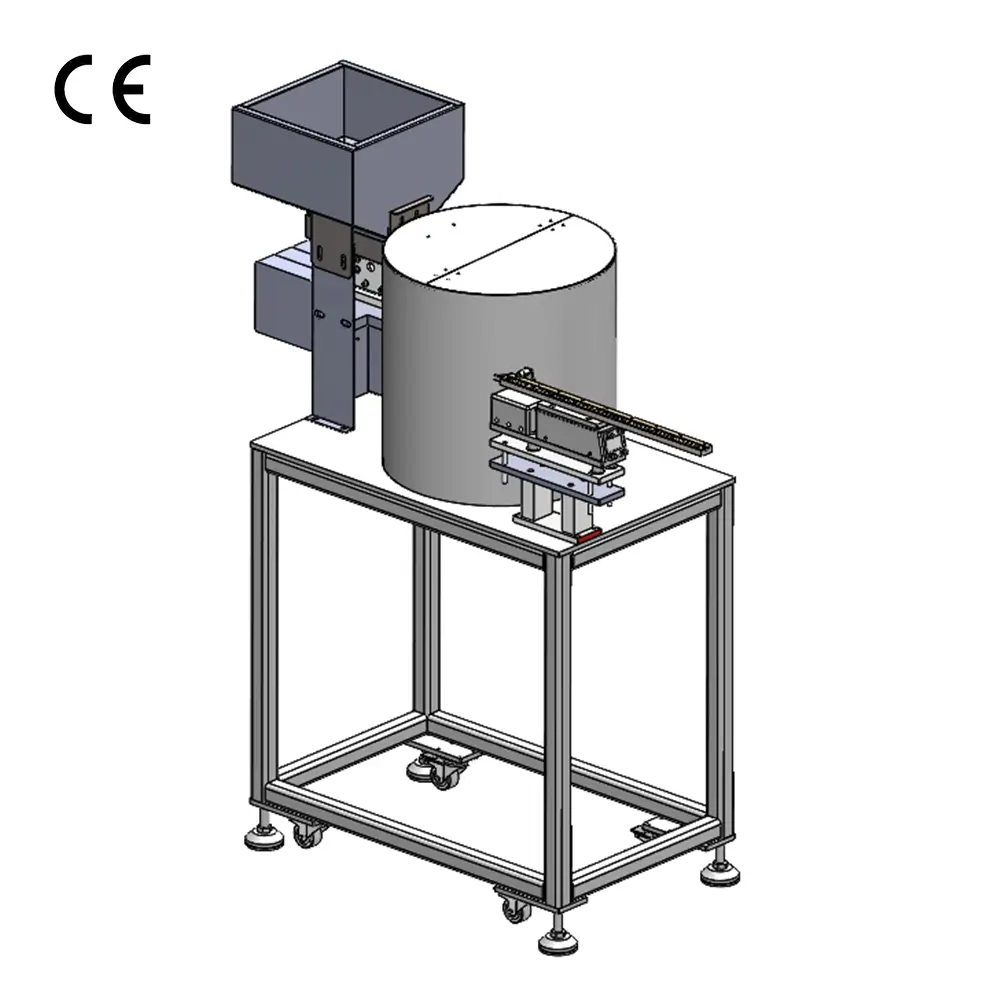

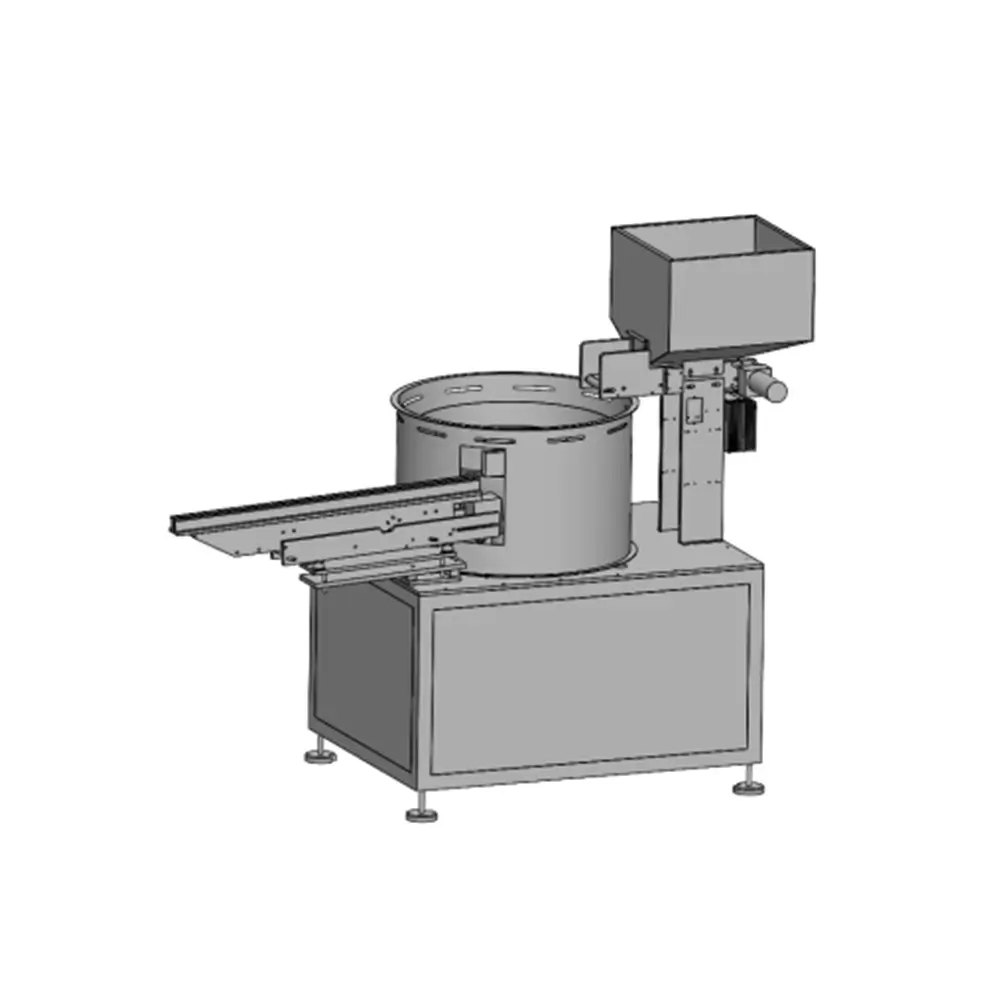

Vibratory bowl feeders, flexible feeders, and centrifugal feeders are “feeders” in industrial automation, which can quickly and accurately deliver parts to designated locations. These “flex feeders” usually work with CCD cameras and “mechanical arm” robots to make automated production lines more intelligent.

- Application in Quality Control (CCD Integration):

- We integrate vibratory bowl feeders and flex feeder systems with CCD cameras for quality control. As parts move, CCD cameras capture images to check for defects or orientation.

- Our computer vision algorithms analyze these images to detect defects and verify part orientation. We automatically sort out or reject faulty parts, ensuring only high-quality components continue in manufacturing.

- Application in Robotic Assembly:

- We often pair vibratory bowl feeders, flex feeders, and centrifugal feeders with robots for automated assembly tasks.

- Robots equipped with grippers or end-effectors can pick up parts from the feeder systems based on their orientation and position. The feeder system ensures a consistent supply of parts to the robot, enabling continuous operation without human intervention.

- The integration of feeder systems with robots streamlines the assembly process, improves efficiency, and reduces cycle times. It also allows for greater flexibility in handling various types of parts or components.

- Application in Pick-and-Place Operations:

- We commonly use vibratory bowl feeders and centrifugal feeders for pick-and-place operations, where precise part positioning is crucial.

- We integrate CCD cameras with the feeder system to give robots feedback on part location and orientation. This helps robots accurately pick up parts and place them at specific locations in the assembly process.

- The combination of feeder systems, CCD cameras, and robots ensures fast and accurate pick-and-place operations, contributing to overall productivity and consistency in manufacturing processes.

- Application in Packaging and Sorting:

- We also integrate feeder systems into packaging and sorting applications for efficient organization and grouping.

- CCD cameras inspect parts for proper orientation and specific features before packaging or sorting. Robots then use inspection results to place parts into the correct packaging containers or sorting bins.

- This integration of feeder systems with CCD cameras and robots optimizes the packaging and sorting process, minimizing errors and increasing throughput.