SWOER Riveting Machine Working Principle and Function

Principle:

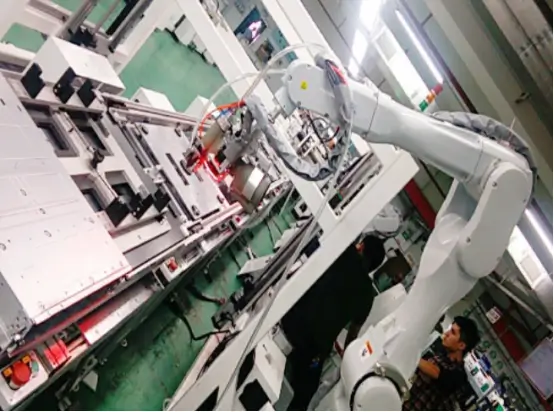

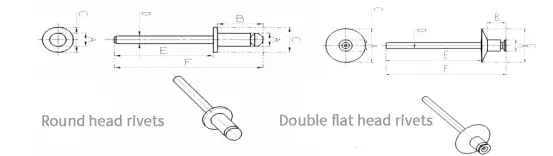

The rivets are sucked into the nozzle of the rivet gun by relying on the negative pressure in the nozzle of the rivet gun; the SWOER automatic rivet machine is an automated version of the automatic rivet gun.

It relies on a machine to automatically arrange and separate the rivets and uses compressed air as power to automatically transport the rivets to the nozzle of the rivet gun through pipes.

Function:

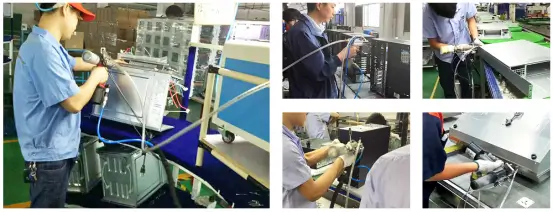

With the SWOER automatic nail-pulling machine, arduous tasks that rely heavily on skilled workers’ hands can be made

Manual nail-pulling operations can be upgraded to automated or unmanned operations.

Effect:

- Save workers and make management easier

The nail-pulling speed is fast, one person can do the job of two people, and there are fewer workers, which reduces management costs or wages.

- High efficiency and cost saving

No need to take out the rivets by hand, saving time on nailing. The output is increased compared to the original, the daily output is completed ahead of schedule, and the production volume is reduced.No more overtime during short-term work hours.

- Super clean and good quality

The rivet is automatically sent to the nozzle of the gun, No need to take it by hand, reducing secondary pollution; hold the product with your left hand, No need to worry.The hole positions are uneven, resulting in reduced output or secondary rework.

- No need to take it by hand, easier

The left-hand does not need to work and can hold the product, which greatly reduces the labor intensity of workers.

- No need to be experienced, easy to learn

It can be operated by both experienced and experienced hands, and no training is required. They can start working immediately; there is no need to worry about the loss of production by experienced hands.