R & D Service

SWOER offers customized design services, tailoring feeding system designs to meet specific client needs. Their professional engineering team utilizes advanced CAD software for mechanical, electrical, and control system designs.

The company manufactures prototypes of feeding systems using methods like 3D printing and machining, subjecting them to initial testing and validation.

SWOER integrates components into feeding systems to ensure seamless operation and optimal performance.

They conduct comprehensive performance testing, covering accuracy, speed, and stability, to meet design specifications and client expectations.

SWOER provides after-sales services, including user training, technical support, and maintenance, ensuring clients receive ongoing assistance throughout the usage lifecycle.

Contact usDesign

SWOER’s design service aims to provide customized solutions for clients’ feeding system needs, tailored to their specific requirements. Through close collaboration with clients and the use of advanced computer-aided design (CAD) software, SWOER integrates mechanical, electrical, and control system designs seamlessly. This customization encompasses parameters such as dimensions, power, and accuracy, ensuring the feeding system perfectly fits the client’s application and operational demands. SWOER’s design team, with its wealth of experience and expertise, delivers high-quality design solutions to clients, ensuring feasibility and practicality in every aspect of the design process.

Contact us

Design Styles and Cases

SWOER’s design styles are characterized by innovation, functionality, and efficiency. Their designs often feature sleek and modern aesthetics combined with robust engineering principles to ensure optimal performance. With a focus on customization, SWOER’s design approach is adaptable to various industries and applications, catering to the specific needs and requirements of each client.

Some of SWOER’s design cases include:

High-precision feeding systems for automotive assembly lines: SWOER has developed feeding systems tailored to the automotive industry, ensuring precise and reliable component delivery for assembly processes.

Flexible feeding solutions for electronics manufacturing: SWOER’s designs accommodate the delicate nature of electronic components, providing flexible feeding solutions that maintain product integrity and production efficiency.

Customized feeding systems for pharmaceutical packaging: SWOER has created feeding systems optimized for pharmaceutical packaging lines, meeting stringent cleanliness and accuracy requirements while enhancing overall productivity.

Automated feeding solutions for food processing: SWOER’s designs for the food industry prioritize hygiene and sanitation while automating the feeding process to improve throughput and minimize manual handling.

Overall, SWOER’s design styles emphasize versatility, performance, and adaptability, resulting in innovative solutions that meet the diverse needs of their clients across various industries.

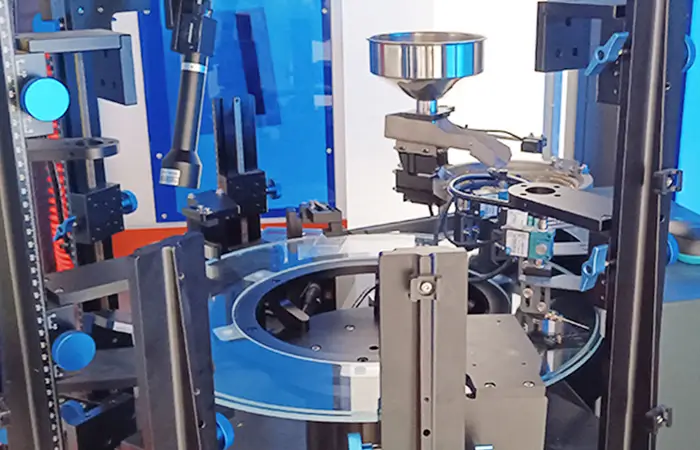

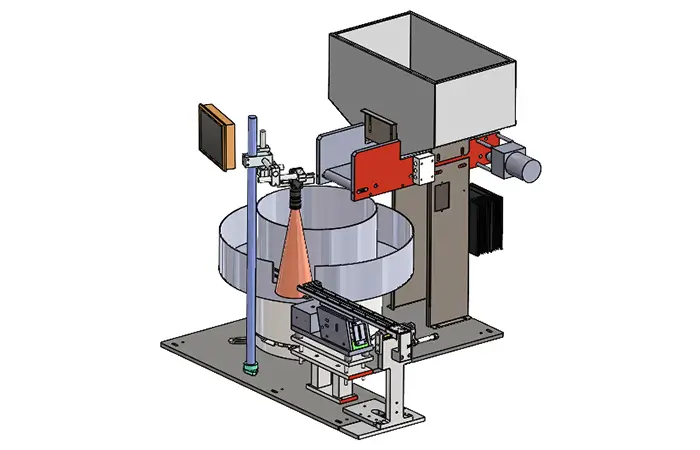

Vibratory Bowl Feeder with CCD System

The 3D design of a vibrating bowl feeder with CCD system integrates precision engineering with advanced technology, ensuring accurate part orientation and seamless integration into automated processes.

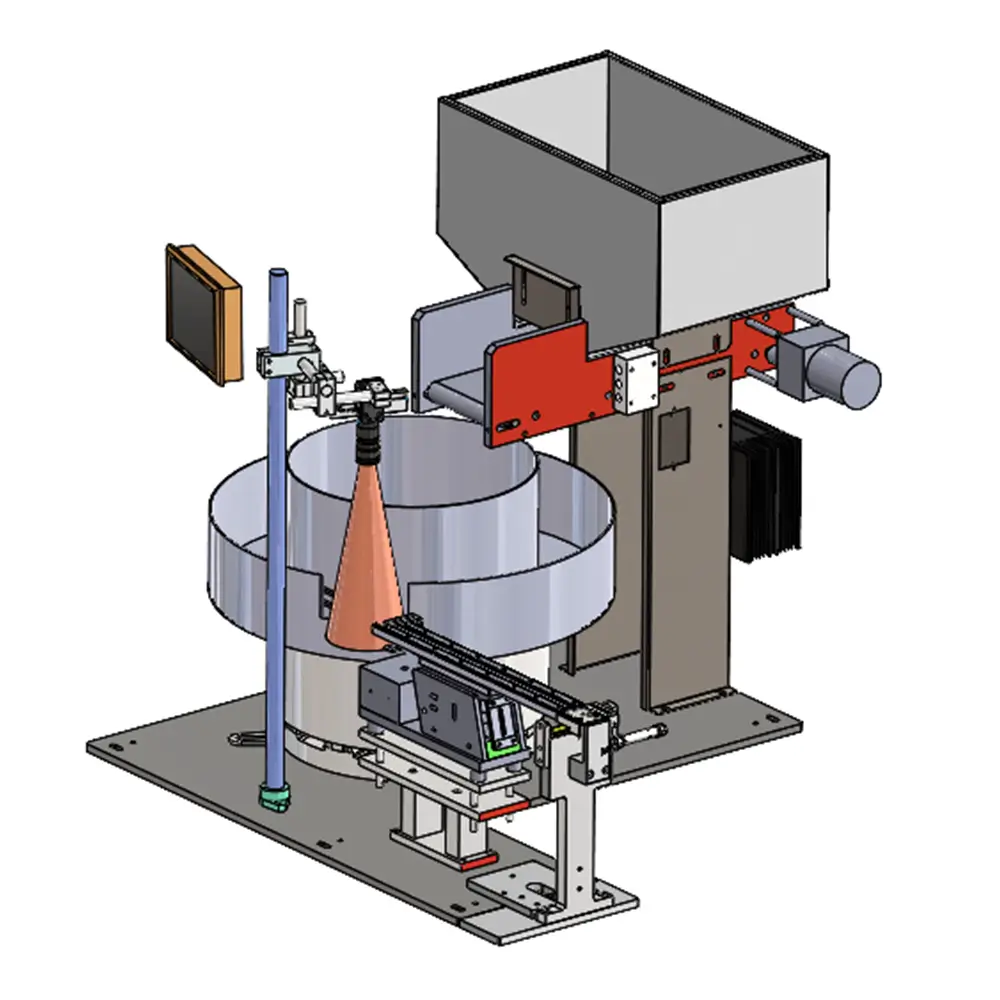

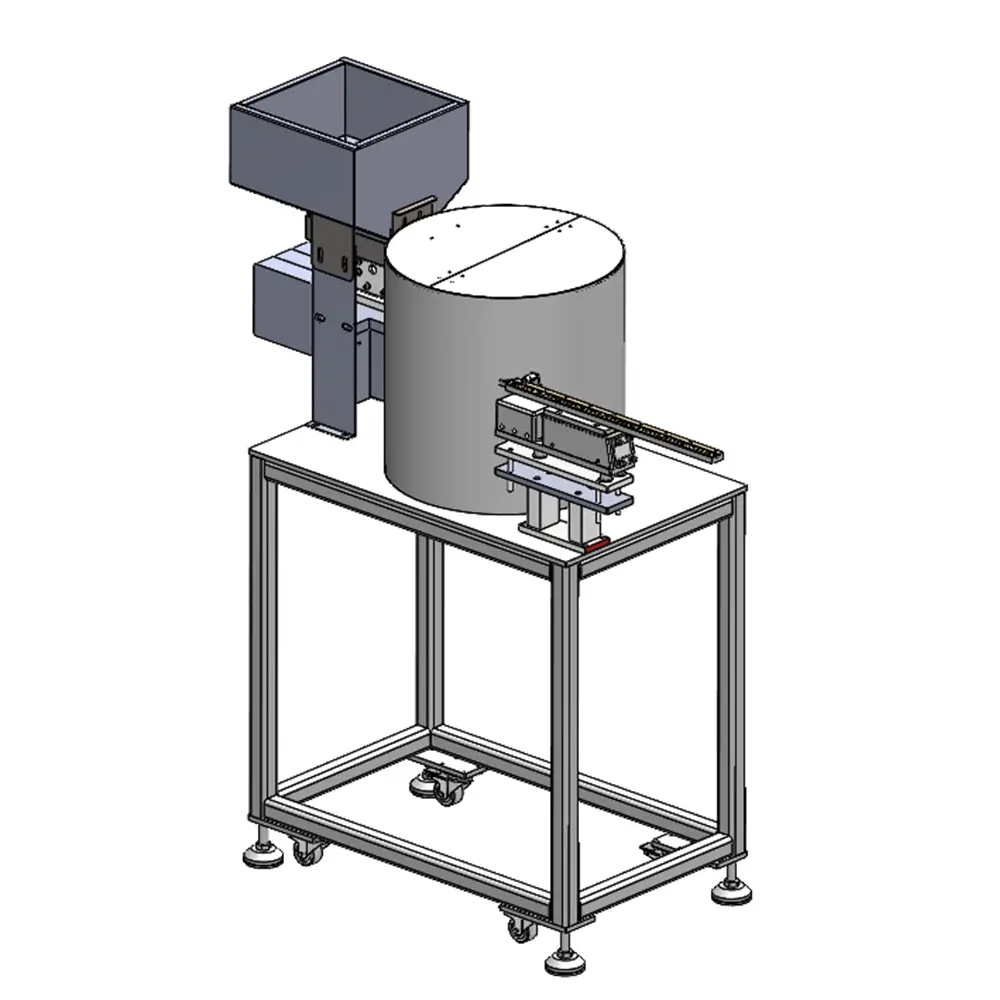

Vibratory Bowl Feeder With Hopper

A vibratory bowl feeder with hopper is an automated system for feeding and orienting parts. It consists of a bowl feeder and a hopper, ensuring continuous supply and precise orientation of parts for industrial processes.

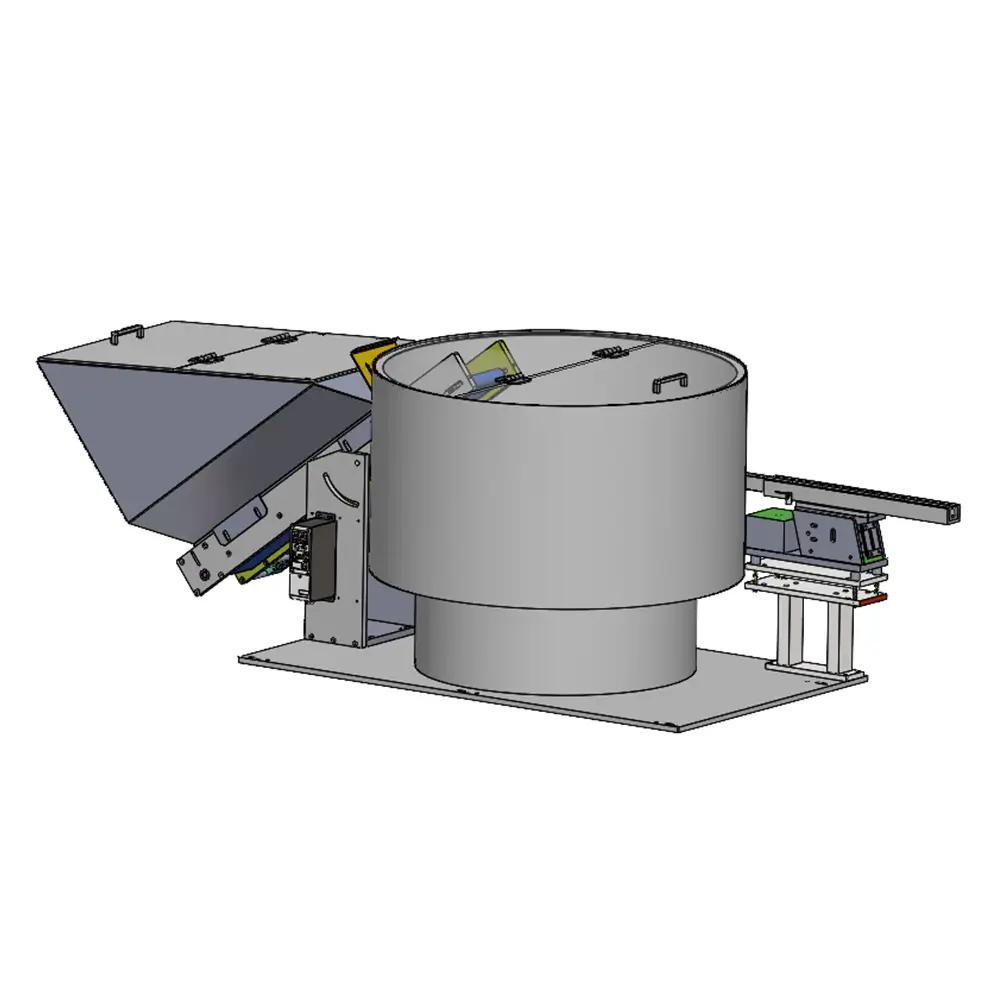

Vibratory Bowl Feeder with Sound Cover

The 3D design of a vibrating bowl feeder with a sound insulation cover combines innovative engineering with noise reduction technology, ensuring efficient part handling while minimizing workplace noise pollution.

Manufacturing

SWOER manufactures its products using a combination of advanced technologies, precision engineering, and rigorous quality control processes. Here’s an overview of how SWOER manufactures its products:

- Design and Engineering: SWOER designs its products using advanced software and engineering expertise.

- Prototyping: Prototypes are created and tested using modern manufacturing techniques.

- Precision Manufacturing: SWOER utilizes state-of-the-art manufacturing processes for precision and consistency.

- Assembly: Skilled technicians assemble components according to strict quality control standards.

- Quality Control: Thorough inspections and testing ensure products meet high-quality standards.

- Packaging and Shipping: Products are carefully packaged and shipped to customers promptly.

After-Sales Service

SWOER’s after-sales service is comprehensive and customer-focused

- User Training: SWOER provides training to ensure customers can operate their products effectively and safely.

- Technical Support: They offer technical assistance to troubleshoot issues and optimize product performance.

- Maintenance Services: SWOER offers maintenance services to keep products running smoothly and extend their lifespan.

- Customer Support: Their support team is available to address any inquiries or concerns promptly.

Need support?

We’re 24/7/365 at your service!

Whether it’s day or night, weekdays or holidays, whenever you need assistance, we’re here for you 24 hours a day, 7 days a week, 365 days a year!

Want Support Now