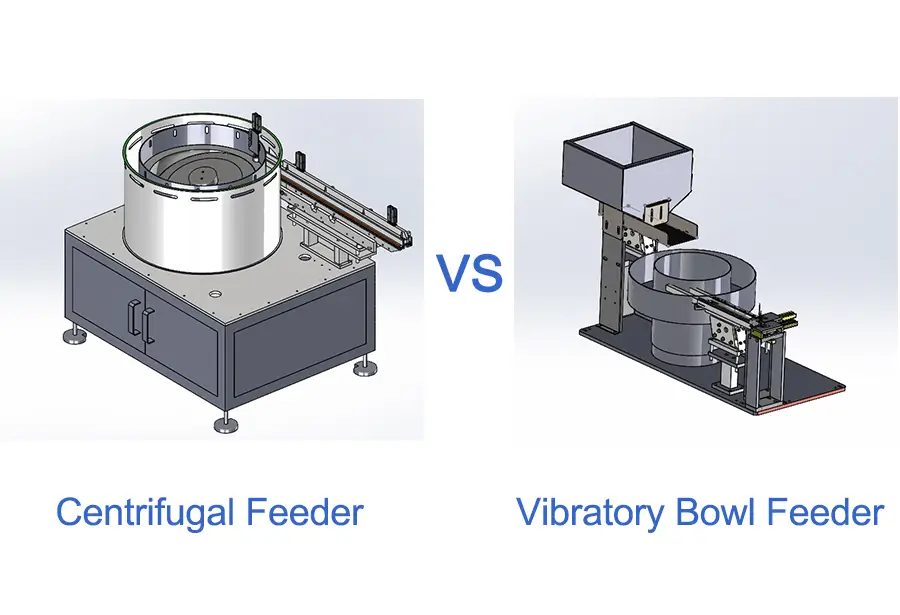

Centrifugal feeders and vibratory bowl feeders are both used in manufacturing and automation to sort and feed parts into production lines. Still, they operate differently and are suited for different applications. Here are the key differences between them:

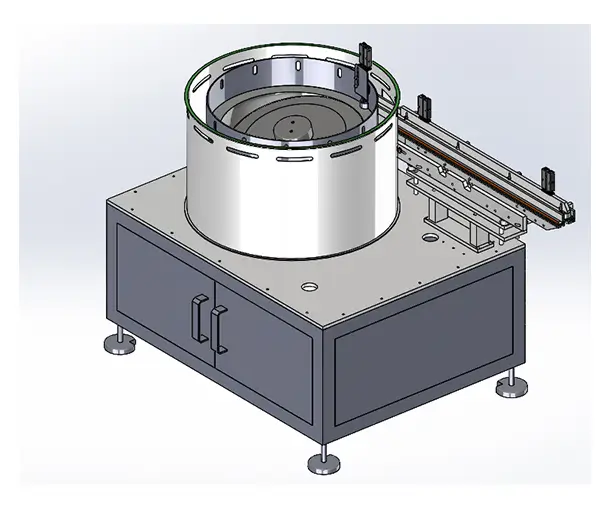

Centrifugal Feeders

Operation:

- Centrifugal feeders use centrifugal force generated by a rotating disc to move parts outward to the edge of the feeder where they are oriented and aligned.

- The parts are then guided along a path, typically using guides or rails, to the next stage of the process.

Applications:

- Suitable for high-speed feeding applications.

- Best for handling parts that are lightweight and can be easily moved by centrifugal force.

- Often used in industries like packaging, pharmaceuticals, and electronics where speed is crucial.

Advantages:

- High-speed operation, capable of feeding hundreds of parts per minute.

- Smooth and gentle handling of parts, reducing the risk of damage.

- Quiet operation compared to vibratory systems.

Disadvantages:

- Limited flexibility in handling different types and shapes of parts without significant modifications.

- Generally more complex and expensive to design and build.

- Requires more precise setup and maintenance.

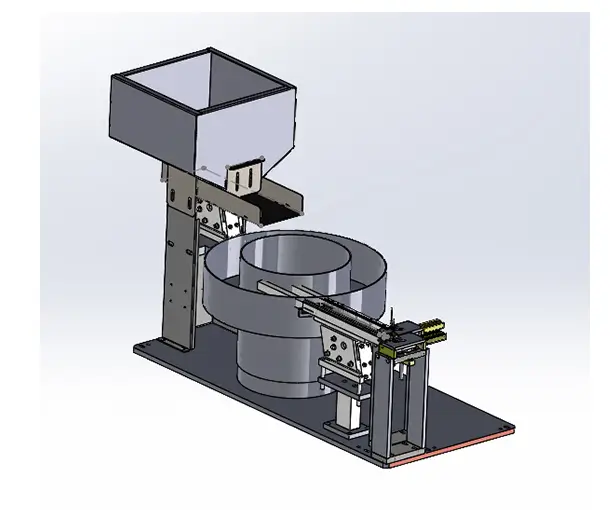

Vibratory Bowl Feeders

Operation:

- Vibratory bowl feeders use electromagnetic vibrations to move parts up a spiral track inside a bowl.

- The vibrations cause the parts to move in a controlled manner, allowing for sorting, orientation, and feeding.

Applications:

- Suitable for a wide range of parts, including small, delicate, and irregularly shaped items.

- Commonly used in the automotive, electronics, pharmaceutical, and packaging industries.

Advantages:

- Highly versatile and can handle a wide variety of part shapes and sizes.

- Easy to adjust and adapt for different parts by changing the tooling.

- Generally lower cost and simpler design compared to centrifugal feeders.

Disadvantages:

- Slower feeding speed compared to centrifugal feeders.

- Can be noisier due to the vibrating action.

- Parts can experience more wear and tear due to the vibrations.

Summary

- Centrifugal Feeders: Best for high-speed applications with lightweight parts, offering smooth and quiet operation but with limited flexibility and higher costs.

- Vibratory Bowl Feeders: More versatile and adaptable for different parts, suitable for a broader range of applications, but slower and potentially noisier.

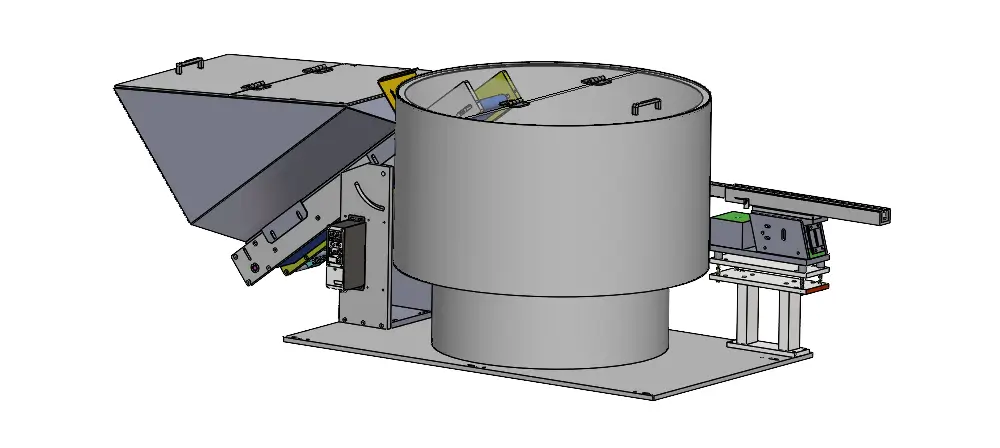

Swoer can customize the vibrating bowl feeder with a soundproof enclosure, which can reduce the noise to a great extent, as shown below:

Contact Us

If you don’t know whether your material or accessories are suitable for centrifugal feeder or vibratory feeder, please contact us.