Key Considerations When Choosing a Vibratory Bowl Feeder

Material Characteristics

When selecting a vibratory bowl feeder, it’s crucial to consider the material’s characteristics. This includes the type of material, its size, shape, and weight, as well as its surface texture and composition. Different materials require different handling techniques, and the feeder must be tailored to accommodate these specific needs.

Feed Rate Requirements

The desired feed rate and volume are essential factors to consider. The feeder must be capable of delivering parts at the required rate to ensure that the production line operates efficiently. A feeder that cannot meet the feed rate requirements can lead to bottlenecks and reduced productivity.

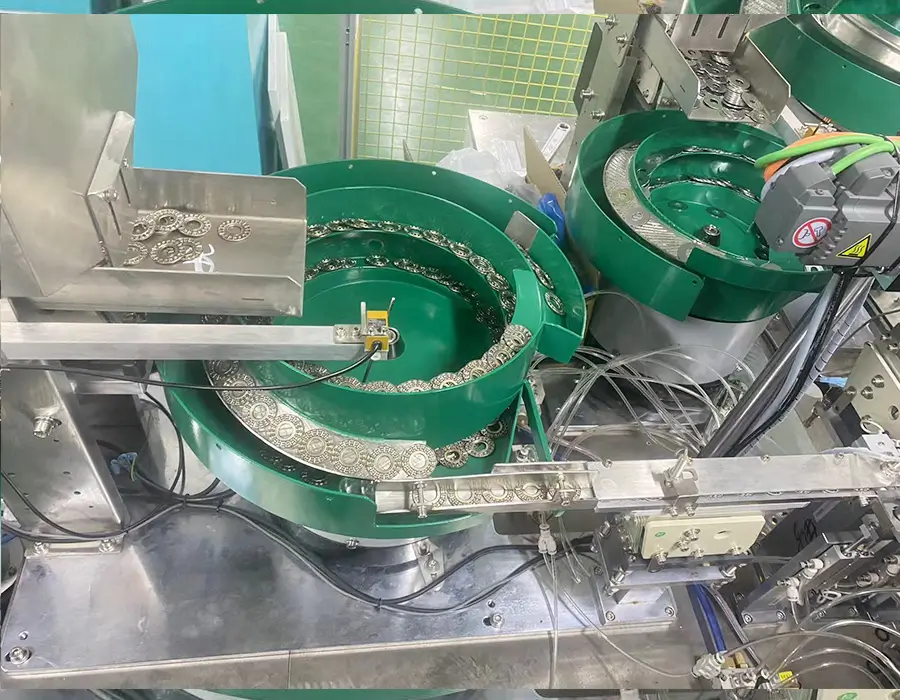

Bowl Design

The design of the bowl is another critical consideration. There are various bowl designs, such as conical, stepped, and cylindrical, each suited to different applications. The choice of bowl design depends on the specific requirements of the parts being fed, including their size, shape, and handling characteristics.

Customization Options

Customization options are often necessary to meet the specific needs of an application. This can include modifications to the bowl design, feed rate, and other features to ensure optimal performance. Custom feeders can be tailored to handle unique materials, sizes, and shapes, providing greater flexibility and efficiency.

Noise and Vibration Levels

Minimizing noise and managing vibration levels are important considerations in selecting a vibratory bowl feeder. Excessive noise can be a safety concern and can disrupt the working environment. Effective strategies to reduce noise and vibration include using sound-dampening materials and optimizing the feeder’s design.

Durability and Maintenance

The durability of the feeder is determined by the materials used in its construction and its overall design. A robust feeder made from high-quality materials will have a longer lifespan and require less maintenance. Additionally, the ease of maintenance and the availability of replacement parts are important factors to consider to minimize downtime and ensure continuous operation.

Evaluating Manufacturers and Suppliers

Reputation and Experience

Choosing a reputable manufacturer with extensive experience in producing vibratory bowl feeders is crucial. A well-established manufacturer is more likely to provide high-quality products and reliable service. Evaluating the manufacturer’s track record and customer reviews can provide valuable insights into their reliability and expertise.

Customer Support and Service

The availability of technical support and customer service is another important consideration. A manufacturer that offers comprehensive support, including installation assistance, troubleshooting, and maintenance services, can help ensure that the feeder operates smoothly and efficiently. Additionally, warranties and after-sales service can provide added peace of mind.

Cost vs. Quality

Balancing cost and quality is essential when selecting a vibratory bowl feeder. While it may be tempting to choose a lower-cost option, it’s important to consider the long-term benefits of investing in a high-quality feeder. A durable and reliable feeder can reduce downtime, maintenance costs, and overall operational expenses, making it a more cost-effective choice in the long run.

Implementation and Integration

Installation Process

The installation process for a vibratory bowl feeder involves several steps, including mounting the feeder, connecting it to the power supply, and calibrating the settings to match the specific application requirements. Understanding the common challenges that can arise during installation, such as alignment issues and electrical connections, can help ensure a smooth and successful setup.

Integration with Existing Systems

Ensuring compatibility with existing production systems is crucial for seamless integration. The feeder must be able to communicate and operate in sync with other components of the production line. This may involve configuring control systems and ensuring that the feeder’s output matches the input requirements of subsequent processes.

Common Questions About Vibratory Bowl Feeders

- What is the typical lifespan of a vibratory bowl feeder?

The lifespan can vary based on usage and maintenance but generally ranges from several years to over a decade.

- How can I reduce the noise level of my feeder?

Implementing sound-dampening materials and optimizing the feeder’s design can help reduce noise levels.

- What are the most common issues with vibratory bowl feeders and how can they be resolved?

Common issues include jamming and misalignment, which can often be resolved through regular maintenance and proper setup.

- How do I determine the right feed rate for my application?

The feed rate should be matched to the production line’s requirements, considering both the volume and speed of part delivery.

- Can vibratory bowl feeders be used for all types of materials?

While vibratory bowl feeders are versatile, they may not be suitable for very delicate or highly irregularly shaped materials. Customization can help accommodate specific needs.

Contact us