- การแนะนำ

- เครื่องป้อนแรงเหวี่ยงคืออะไร?

- บทบาทของระบบฮอปเปอร์ในเครื่องป้อนแบบแรงเหวี่ยง

- เครื่องป้อนแรงเหวี่ยงในชุดเข็มฉีดยา

- ข้อดีของการใช้เครื่องป้อนแบบแรงเหวี่ยงกับระบบฮอปเปอร์

- ข้อควรพิจารณาในการออกแบบเครื่องป้อนแบบแรงเหวี่ยง

- บทสรุป

การแนะนำ

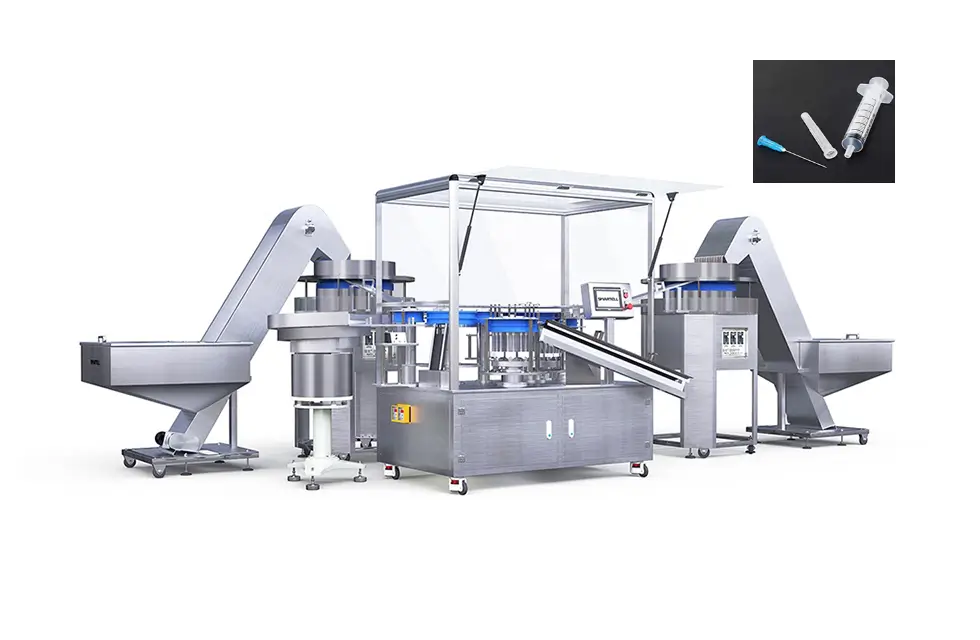

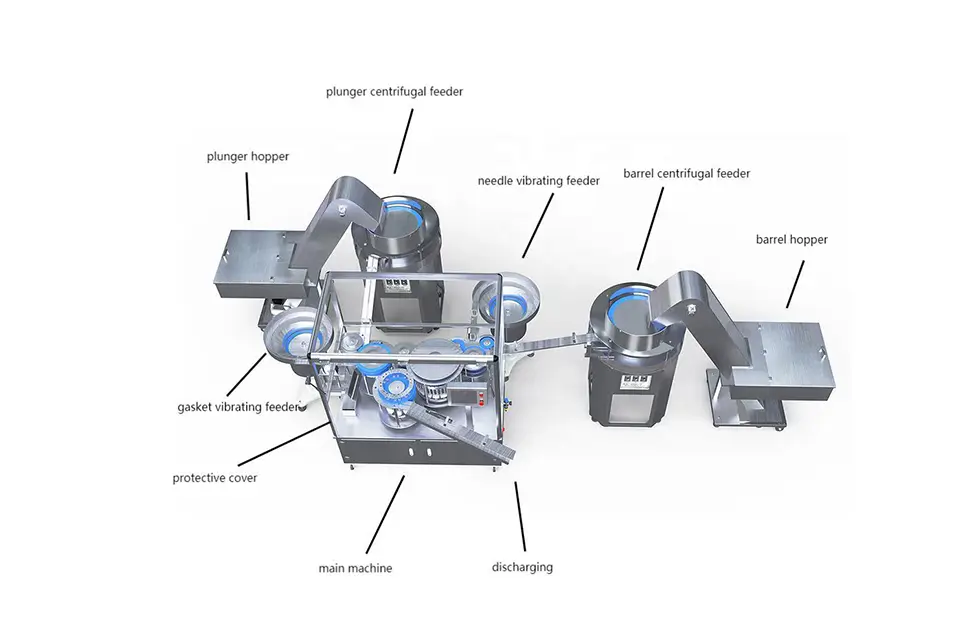

ในการผลิตอัตโนมัติ โดยเฉพาะในอุตสาหกรรมที่มีความแม่นยำสูง เช่น การประกอบเข็มฉีดยา ตัวป้อนแบบแรงเหวี่ยงที่จับคู่กับระบบฮอปเปอร์มีบทบาทสำคัญในการรับรองการป้อนชิ้นส่วนที่มีประสิทธิภาพและแม่นยำ บล็อกนี้จะตรวจสอบการผสานรวมตัวป้อนแบบแรงเหวี่ยงกับระบบฮอปเปอร์และการประยุกต์ใช้ในเครื่องประกอบเข็มฉีดยาอัตโนมัติ

เครื่องป้อนแรงเหวี่ยงคืออะไร?

ก เครื่องป้อนแบบแรงเหวี่ยง คือเครื่องป้อนชิ้นส่วนอัตโนมัติที่ใช้การเคลื่อนที่แบบหมุนเพื่อวางแนวและส่งมอบชิ้นส่วน ชิ้นส่วนที่หมุนในชามหรือกลไกหมุน เครื่องป้อนแบบแรงเหวี่ยงช่วยให้มั่นใจว่าชิ้นส่วนจะถูกป้อนในทิศทางที่ถูกต้อง และพร้อมสำหรับการประกอบหรือการประมวลผลเพิ่มเติม

เครื่องป้อนแรงเหวี่ยงมีอยู่หลายประเภท:

- เครื่องป้อนชามแบบแรงเหวี่ยงเหมาะอย่างยิ่งสำหรับชิ้นส่วนขนาดเล็ก และมักใช้ในงานที่ต้องมีความแม่นยำสูง

- เครื่องป้อนแบบหมุนเหวี่ยงเหมาะสำหรับชิ้นส่วนที่มีขนาดใหญ่และหนักกว่า และสามารถจัดการกับปริมาณงานที่สูงขึ้นโดยยังคงความแม่นยำไว้ได้

ตัวป้อนเหล่านี้ช่วยวางทิศทางชิ้นส่วนเข็มฉีดยา เช่น ลูกสูบและกระบอกสูบในชุดเข็มฉีดยา ทำให้แน่ใจว่าชิ้นส่วนต่างๆ จะอยู่ในตำแหน่งที่ถูกต้องสำหรับการประกอบ

บทบาทของระบบฮอปเปอร์ในเครื่องป้อนแบบแรงเหวี่ยง

ระบบฮอปเปอร์เป็นหน่วยจัดเก็บจำนวนมากที่จ่ายชิ้นส่วนให้กับ เครื่องป้อนแบบแรงเหวี่ยงช่วยให้มั่นใจได้ว่าจะมีการจัดหาชิ้นส่วนอย่างต่อเนื่องและสม่ำเสมอ ป้องกันการหยุดชะงักหรือความล่าช้าในกระบวนการผลิต ด้วยการทำงานร่วมกับตัวป้อนแบบแรงเหวี่ยง ถังบรรจุจึงสามารถประมวลผลชิ้นส่วนจำนวนมากได้โดยอัตโนมัติ ลดการดำเนินการด้วยมือ

ในการประกอบเข็มฉีดยา ซึ่งจำเป็นต้องป้อนส่วนประกอบอย่างรวดเร็วและสม่ำเสมอ ระบบถังบรรจุมีความสำคัญอย่างยิ่งในการรักษาความเร็วและประสิทธิภาพของสายการผลิต

เครื่องป้อนแรงเหวี่ยงในชุดเข็มฉีดยา

สายการประกอบเข็มฉีดยาต้องใช้ความแม่นยำระดับสูง และเครื่องป้อนชิ้นส่วนแบบแรงเหวี่ยงจึงเหมาะอย่างยิ่งสำหรับงานนี้ เครื่องป้อนเหล่านี้จะปรับทิศทางและป้อนชิ้นส่วนที่บอบบาง เช่น กระบอกฉีดยา ลูกสูบ และเข็มได้อย่างมีประสิทธิภาพ แรงเหวี่ยงในเครื่องป้อนเหล่านี้ช่วยให้มั่นใจได้ว่าชิ้นส่วนต่างๆ จะถูกนำเสนอในทิศทางที่ถูกต้องโดยไม่ก่อให้เกิดความเสียหาย ซึ่งมีความสำคัญอย่างยิ่งสำหรับชิ้นส่วนที่บอบบาง

การผสานรวมตัวป้อนแบบแรงเหวี่ยงเข้ากับเครื่องประกอบเข็มฉีดยาช่วยเพิ่มความเร็วและความแม่นยำของสายการผลิต ชิ้นส่วนต่างๆ จะถูกป้อนอย่างราบรื่นและสม่ำเสมอ ทำให้มั่นใจได้ว่ากระบวนการประกอบจะรวดเร็วและมีประสิทธิภาพ

ข้อดีของการใช้เครื่องป้อนแบบแรงเหวี่ยงกับระบบฮอปเปอร์

- เพิ่มประสิทธิภาพ:เครื่องป้อนแบบแรงเหวี่ยงช่วยให้มั่นใจได้ว่าชิ้นส่วนจะถูกป้อนอย่างต่อเนื่องโดยไม่ล่าช้า ช่วยเร่งความเร็วสายการประกอบและลดเวลาหยุดทำงาน

- ความแม่นยำสูง:ตัวป้อนเหล่านี้กำหนดทิศทางของชิ้นส่วนอย่างแม่นยำซึ่งมีความสำคัญต่อการประกอบเข็มฉีดยาซึ่งความแม่นยำเป็นสิ่งสำคัญ

- ลดความเสียหายของชิ้นส่วนการจัดการอย่างอ่อนโยนโดยตัวป้อนแบบแรงเหวี่ยงช่วยป้องกันความเสียหายต่อชิ้นส่วนที่บอบบาง และช่วยรักษาคุณภาพของผลิตภัณฑ์

- การทำงานต่อเนื่อง:ระบบถังบรรจุทำให้ชิ้นส่วนไหลเวียนได้อย่างไม่หยุดชะงัก ช่วยให้สายการประกอบทำงานได้อย่างราบรื่นและมีประสิทธิภาพตลอดเวลา

ข้อควรพิจารณาในการออกแบบเครื่องป้อนแบบแรงเหวี่ยง

ในการออกแบบระบบป้อนแรงเหวี่ยงสำหรับการประกอบเข็มฉีดยา ปัจจัยหลักได้แก่:

- ขนาดและรูปร่างชิ้นส่วน: การออกแบบตัวป้อนควรปรับให้เหมาะกับขนาดและรูปร่างของส่วนประกอบของเข็มฉีดยา ตัวป้อนแบบชามเหวี่ยงเหมาะสำหรับชิ้นส่วนขนาดเล็กที่มีลักษณะสม่ำเสมอ ในขณะที่ตัวป้อนแบบโรตารีเหวี่ยงเหมาะสำหรับชิ้นส่วนขนาดใหญ่และหนักกว่า

- ความต้องการวัสดุ:ระบบป้อนจะต้องสามารถรองรับวัสดุที่ใช้ในส่วนประกอบของเข็มฉีดยาได้ ไม่ว่าจะเปราะบางหรือต้องการการจัดการเป็นพิเศษ

บทสรุป

การบูรณาการของ เครื่องป้อนแบบแรงเหวี่ยงพร้อมระบบถังบรรจุ เครื่องประกอบเข็มฉีดยาอัตโนมัติช่วยเพิ่มประสิทธิภาพ ความแม่นยำ และปริมาณงานได้อย่างมาก โดยการทำให้กระบวนการป้อนชิ้นส่วนเป็นแบบอัตโนมัติ ระบบเหล่านี้จะช่วยลดการดำเนินการด้วยมือ เพิ่มความเร็วในการผลิต และรับรองผลลัพธ์ที่มีคุณภาพสูง ในขณะที่เทคโนโลยีอัตโนมัติยังคงพัฒนาต่อไป เครื่องป้อนแบบแรงเหวี่ยงจะยังคงเป็นส่วนประกอบสำคัญในการผลิตที่มีความแม่นยำสูง โดยให้ประโยชน์มากมายในอุตสาหกรรมต่างๆ เช่น การผลิตเข็มฉีดยา

ติดต่อเรา

วันนี้มาหารือถึงความต้องการระบบป้อนแรงเหวี่ยงของคุณ