Are you looking for a vibratory bowl feeder that can perfectly fit your production line?

As one of the leading manufacturers, Swoer offers customized vibratory bowl feeder solutions to meet unique needs.

What to customize?

- Part shape and size: We design the optimal feeding track and sorting mechanism according to the shape, size, weight and other characteristics of your parts.

- Feeding speed and accuracy: You can specify the required feeding speed and accuracy. In response, we will meticulously meet your requirements by carefully adjusting parameters such as vibration frequency and track inclination.

- Arrangement and direction: Moreover, we can precisely arrange and orient the parts according to your next process requirements, thus ensuring seamless integration and efficiency.

- Material selection: We provide a variety of material options for different working conditions and materials to ensure the durability and corrosion resistance of the vibration plate.

- Control system: We can provide different types of control systems according to your automation requirements to achieve precise control of the vibration plate.

- Other special requirements: In addition to the basic parameters, we can further customize the design. For example, if you need anti-static or dustproof features, we can incorporate these specifications to meet your needs.

Why choose Swoer to customize the vibratory bowl feeder?

- Professional customization:With many years of experience in vibration plate design and manufacturing, Swoer can provide you with professional customization solutions.

- Quality assurance: Use high-quality materials and advanced technology to ensure stable and reliable product quality.

- Timely delivery:With efficient production lines and a complete supply chain, we guarantee on-time delivery.

- After-sales service: Provide comprehensive after-sales service, including installation and commissioning, repair and maintenance, etc.

Customization process

- Demand communication: You provide part drawings, samples or detailed parameters, and we communicate with you in depth to understand your specific needs.

- Solution design: Our engineers design the best vibration plate solution according to your needs and issue detailed design drawings.

- Prototype production: Once you confirm the solution, we will create a prototype. Subsequently, we will thoroughly test and verify it. Then, for your confirmation, we will take a detailed video of the prototype.

- Mass production: After the prototype test is qualified, we will enter the mass production stage.

- Delivery acceptance:After the product is delivered, we will assist you with installation and commissioning, and provide detailed instructions for use.

Swoer customized vibratory bowl feeder makes your production more efficient!

Related Blogs

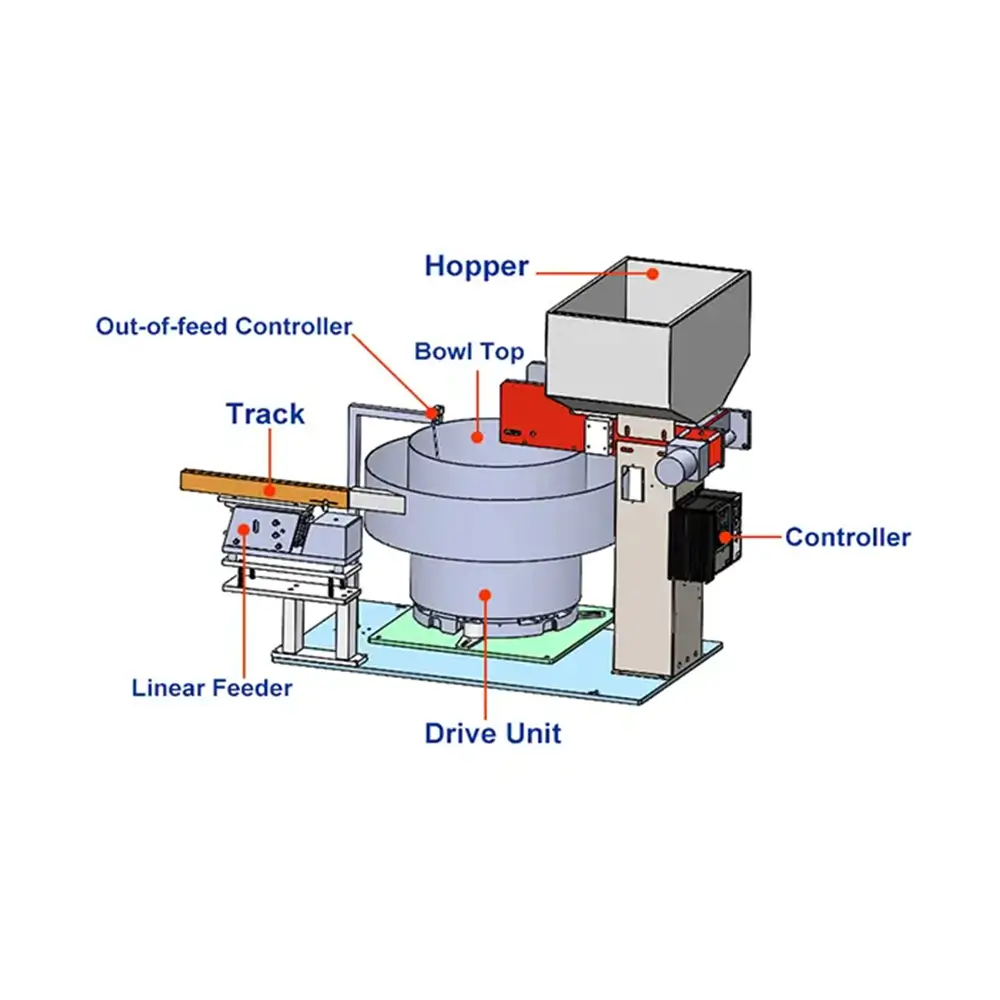

- What is a Vibratory Bowl Feeder?

- How Does Vibratory Bowl Feeder Work?

- How to Design a Vibratory Bowl Feeder

Contact us

If you are interested in our customized services, please click the online chat window on the right or fill in the form below to contact us!