A vibratory bowl feeder operates by using controlled vibrations to move, sort, and orient parts within a circular bowl. The feeder’s base unit generates vibrations that transfer to the bowl, causing the parts to move along a spiral track or multiple tracks.

As the parts move upwards due to the vibrations, they interact with the track’s incline and the bowl’s geometry. Consequently, this interaction aligns and orients them in the desired position. Once they are oriented, the feeder then guides the parts towards the exit point and discharges them. This final step prepares the parts for further processing or assembly.

This process allows for efficient and consistent feeding of parts in automated manufacturing and assembly applications across various industries.

Here’s a detailed explanation of how it works:

Principle of Operation

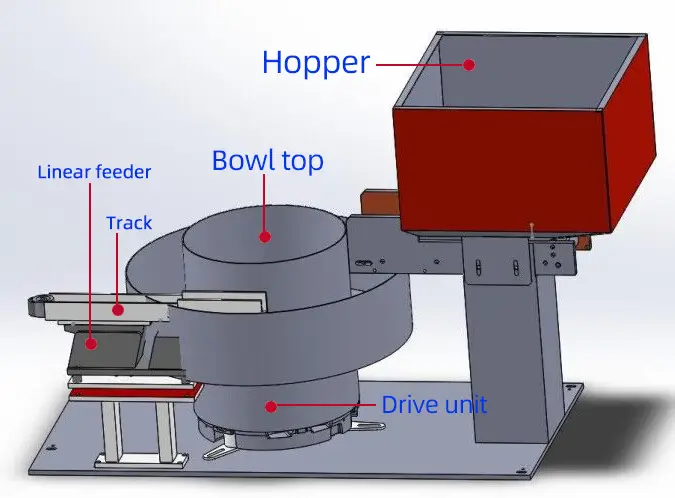

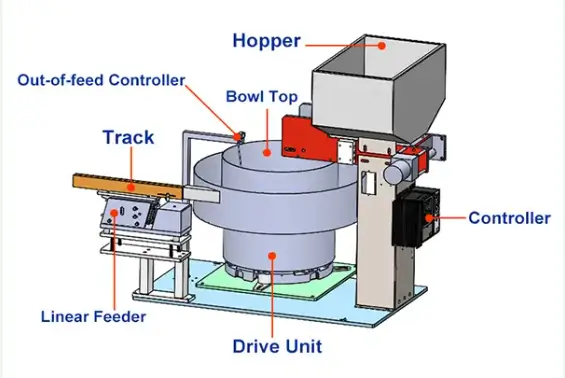

A vibratory bowl feeder consists of a bowl, a base unit, and a control system. The bowl is mounted on the base unit, which generates vibrations to move the parts along the bowl and toward the exit point.

Bowl Vibration

The base unit generates vibrations and transfers them to the bowl.These vibrations cause the parts inside the bowl to move upwards along the track, creating a consistent and smooth flow of components.

Part Orientation

As the parts move upwards due to the vibrations, they simultaneously interact with the track’s incline and the bowl’s geometry. Consequently, this interaction guides their alignment and orientation.This interaction helps align and orient the parts in the desired position, ensuring they are all facing the same direction as they reach the top of the track.

Exit and Feeding

Once the parts reach the top of the track, the system, therefore, aligns and orients them correctly. As a result, it prepares the parts effectively for further processing or assembly. An exit mechanism, usually a ramp or conveyor, guides the oriented parts out of the bowl and into the next stage of the production process.

Key Components and Their Functions

Bowl:

The bowl is the main component where the parts are placed. It is designed with specific geometries and tracks to facilitate the movement and orientation of the parts.

Base Unit:

The base unit houses the electromagnetic or mechanical drive responsible for generating the vibrations required for the feeder’s operation.

Control System:

The control system regulates the frequency and intensity of the vibrations, allowing users to adjust settings and monitor the feeder’s performance.

In conclusion, a vibratory bowl feeder uses vibrations to move, orient, and feed parts in a controlled manner, making it an essential tool in automated manufacturing and assembly processes across various industries.

Frequently Asked Questions (FAQs)

1. What is a vibratory bowl feeder?

Please click here to learn more about what a vibratory bowl feeder is.

2. What materials can be handled by vibratory bowl feeders?

Vibratory bowl feeders can handle a wide range of materials, including metal, plastic, rubber, and more.

3. How do I choose the right vibratory bowl feeder for my application?

Consider factors such as material type, size, and weight of the parts, as well as the required feed rate and orientation.

4. What are the maintenance requirements for vibratory bowl feeders?

Regular cleaning, inspection, and lubrication are essential for maintaining optimal performance.