Introduction

Definition and Importance of Vibratory Bowl Feeders

Vibratory bowl feeders are vital in automated production. These devices sort, orient, and feed various small parts efficiently. They ensure a seamless workflow in manufacturing processes. By vibrating and moving items, vibratory bowl feeders automate tasks that need significant manual effort.

Overview of Automated Production

Automated production involves using control systems like robots and computers. These systems handle manufacturing processes with minimal human intervention. Consequently, this approach enhances productivity, consistency and precision are enhanced, while operational costs and human error decrease. Moreover, vibratory bowl feeders play a key role in this automation. Specifically, they are crucial in high-speed production environments, where both precision and reliability are essential.

The Working Principle of Vibratory Bowl Feeders

Basic Mechanics

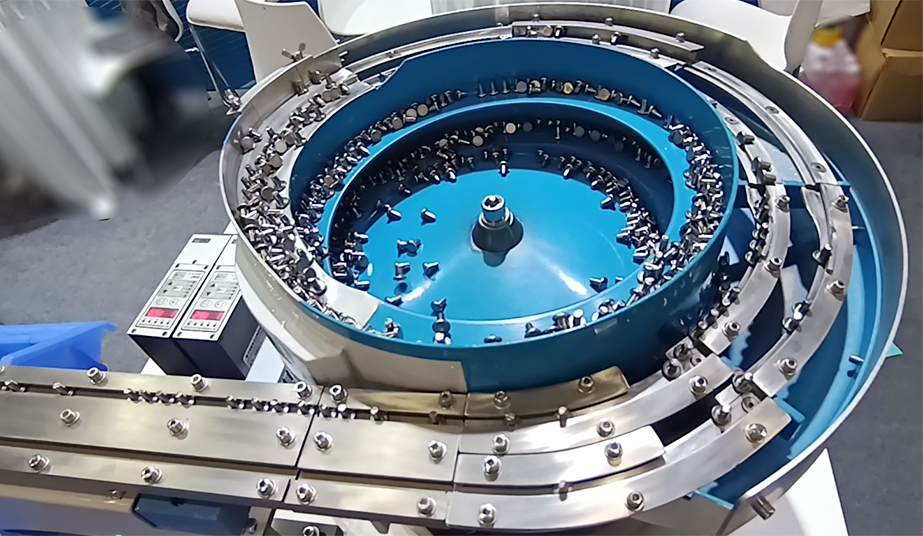

Vibratory bowl feeders operate through the controlled vibration of a bowl containing the parts to be fed. The vibrations move parts up a spiraling track in the bowl, sorting and orienting them as they reach the output.

Key Components

Key components of a vibratory bowl feeder are the bowl, drive unit, control system, and tracks for guiding and orienting parts. Engineers must precisely design each component to ensure optimal performance and reliability.

How They Integrate with Automated Systems

In an automated production line, robotic arms, conveyors, and sensors connect with vibratory bowl feeders for efficient, continuous part flow.

Applications in Various Industries

Electronics Manufacturing

- Component Sorting and Orientation: Vibratory bowl feeders efficiently sort and orient small components like resistors, capacitors, and ICs in electronics.They ensure the components are correctly positioned for assembly.

- Assembly Line Integration: These feeders seamlessly integrate with pick-and-place machines and automated assembly lines, facilitating high-speed, precise manufacturing processes.

Automotive Industry

- Fastener Sorting: In automotive manufacturing, vibratory bowl feeders sort and feed fasteners like screws, nuts, and bolts. They ensure the fasteners are correctly oriented for assembly.

- Parts Feeding for Assembly: They feed larger parts like gaskets and clips, streamlining the assembly process and boosting efficiency.

Advantages of Using Vibratory Bowl Feeders

- High Efficiency and Speed: Vibratory bowl feeders handle high volumes of parts quickly, ideal for fast production lines.

- Flexibility and Versatility: We customize them to handle various parts, from tiny electronic components to larger automotive parts.

- Cost-Effectiveness: Automating sorting and feeding with vibratory bowl feeders reduces manual labor and minimizes production costs.

- Minimal Human Intervention: These feeders operate with minimal oversight, reducing human error and increasing production reliability.

- Enhanced Quality Control: Consistent and precise feeding of parts improves the quality and consistency of the final product.

Customization and Optimization

- Tailoring Feeders to Specific Applications: We customize vibratory bowl feeders to fit various industry requirements, ensuring optimal performance.

- Advanced Control Systems: Modern vibratory bowl feeders have advanced control systems for precise vibration adjustments, enhancing flexibility and efficiency.

- Integration with IoT and Industry 4.0 Technologies: IoT and Industry 4.0 integration allows real-time monitoring and optimization, boosting productivity and reducing downtime.

Challenges and Solutions

- Handling Fragile or Irregular Items: Special feeders and gentle vibrations handle fragile or irregular items without causing damage.

- Noise and Vibration Management: Advanced dampening technologies reduce noise and vibration, minimizing their impact on the production environment.

- Maintenance and Longevity: Regular maintenance and high-quality materials extend the lifespan of vibratory bowl feeders and ensure consistent performance.

4o mini

Future Trends in Vibratory Bowl Feeders

- Technological Advancements: Ongoing advancements in materials and control systems are improving the performance and versatility of vibratory bowl feeders.

- Increasing Use of AI and Machine Learning: We use AI and machine learning in feeders to enhance maintenance and optimize performance.

- Trends Towards More Sustainable and Energy-Efficient Designs: We focus on sustainable, energy-efficient vibratory bowl feeders to meet regulations and cut operational costs.

Case Studies

- Successful Implementations in Various Industries: We highlight real-world examples of industries using vibratory bowl feeders, showing their benefits and best practices.

- Lessons Learned and Best Practices: We provide insights and lessons from these implementations, offering guidance for optimizing vibratory bowl feeders.

FAQs

What is a Vibratory Bowl Feeder?

How Does Vibratory Bowl Feeder work?

How to Adjust a Vibratory Bowl Feeder? – A Detailed Guide

How to Choose a Vibratory Bowl Feeder That’s Right for you?

Get a Free quote