Table of Contents

- Brief overview of material handling systems.

- Introduction to Flexible Feeders and Vibratory Feeders.

- Definition and features of flexible feeders.

- How they adapt to different parts and materials.

- Integration with robots, vision systems, and other automation technologies.

- Definition and operation of vibratory feeders.

- How they use vibration to move materials.

- Ideal applications for vibratory feeders (e.g., granules, bulk material).

- Material Adaptability: Flexible feeders vs. vibratory feeders.

- Functionality: Complex automation vs. simple, high-speed material handling.

- Precision and Integration: Flexibility of integration with other systems.

- Industries and scenarios where flexible feeders excel (robotic sorting, assembly lines).

- Industries that commonly use vibratory feeders include food processing and pharmaceuticals.

- Summary of when to use flexible feeders versus vibratory feeders based on needs.

- Recommendations for businesses in choosing the right feeder.

Introduction

Flexible feeders and vibratory feeders serve essential roles in automated material handling equipment, but they have some key differences in design, function and application.

Flexible Feeder

Flexible feeders adjust easily to different material shapes and sizes. Automated production lines often use them because they adapt to various types of parts and integrate with other systems, such as robots.

Features

- Strong adaptability: Flexible feeders can handle parts of various shapes, sizes, and materials and can even handle complex or irregularly shaped items.

- Versatility: Flex feeders usually integrates with vision systems, robotic systems, or other automated equipment for precise material sorting, conveying, and positioning.

- Integration: Flexible feeders usually come equipped with multiple sensors and control systems, enabling them to flexibly respond to a variety of work requirements and making them suitable for various applications in automated production environments.

Application

Flexible feeders commonly handle different types of materials in scenarios such as robot sorting, precision assembly lines, food packaging, and more.

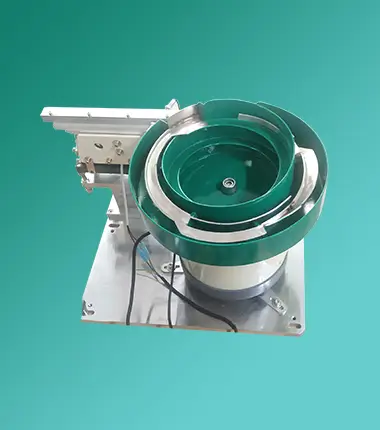

Vibratory Feeder

Vibratory feeders are device that uses vibration (usually electromagnetic or mechanical vibration) to guide and convey materials. Vibratory feeders control the vibration frequency and amplitude to move materials along the feeding trough or pipe.

Features

- Stability: Vibratory feeders accurately control the flow of materials through the vibration system, and are particularly suitable for regular and standardized material conveying.

- Efficiency: Suitable for scenarios where large quantities of materials need to be fed quickly, especially in high-precision and high-speed production lines, where materials can be fed at a stable rate.

- Single function: Vibratory feeders mainly handle materials with regular shapes and similar sizes, and are usually not as adaptable to various complex materials as flexible feeders. Of course, the vibratory parts feeder also integrates with visual inspection.

Application

Commonly used in food, pharmaceutical, chemical, and other industries, especially suitable for the conveying of granular and granular materials.

Main Differences

| Features | Flexible Feeders | Vibratory Feeders |

| Adaptability | Highly adaptable, can handle parts of various shapes and sizes. | Mainly handles materials with regular shapes and uniform sizes. |

| Function | Can be integrated with robots, vision systems, etc. to achieve more complex material handling. | Mainly transmits materials through vibration, suitable for efficient and large-scale material transportation. |

| Material Type | Suitable for parts of irregular shapes and different sizes. | Suitable for regular and standardized materials (such as particles and granular materials). |

| Precision and Integration | High precision, can be integrated with other automation systems. | Mainly used for stable transportation, usually not integrated with other systems (such as robots). |

| Complexity | More complex, usually requires advanced control and sensor systems. | Relatively simple, mainly relying on the vibration system to control the flow of materials. |

| Typical Applications | Automated production lines, robot sorting, precision assembly, food packaging, etc. | Material transportation such as screws, nuts, washers, etc., basic material flow on the production line. |

Conclusion

- Flexible feeders are highly adaptable and versatile feeding systems that can handle materials of different shapes, sizes, and types. Automated robotic systems often use them.

- Vibratory feeders mainly deliver regular, granular, or uniformly sized materials steadily. It is suitable for simpler material flows and large-scale delivery needs.

When choosing which feeder to use, you should decide based on the type of material being handled, the application environment, and whether it needs integration with other automated equipment.