Vibratory Bowl Feeders

Vibratory bowl feeders are devices used for automatic feeding and directional conveying of materials and are commonly used in industrial automation. Their working principle is to use vibration to make the material rise along a spiral track, and then use a guide chute or pipe to transport it directionally to a specified position.

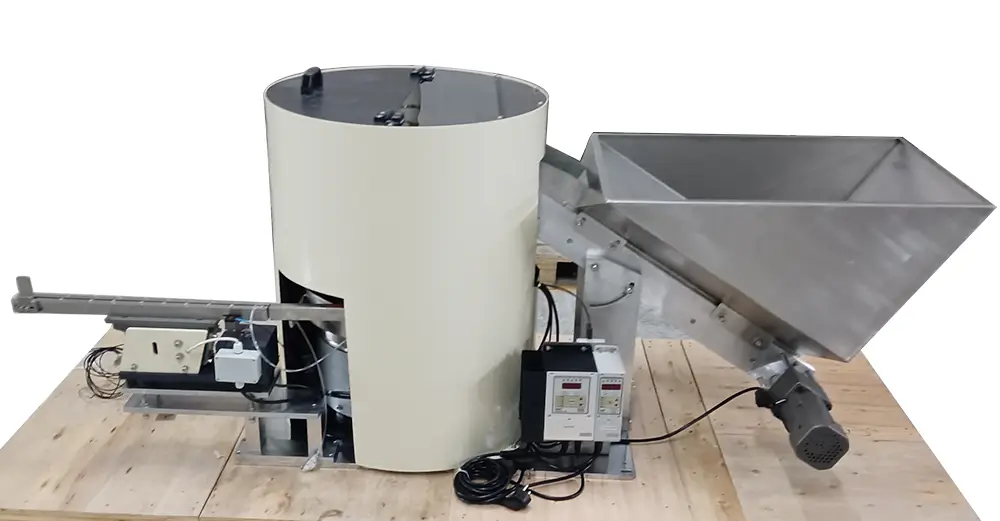

A typical vibratory bowl feeder consists of the following parts:

- Hopper: Used to hold the material to be fed.

- Baseplate: Supports the hopper and vibrator.

- Vibrator: A device that generates vibration force, typically an electromagnetic or pneumatic vibrator.

- Guide chute or pipe: Used to guide the material for directional conveying.

- Controller: Used to control the operation of the vibratory feeder.

Vibratory bowl feeders have the following characteristics:

- Adjustable feed rate.

- Adjustable feed direction.

- Sorts materials directionally.

- Works with other automated equipment.

Vibratory feeders find broad applications across industries like electronics, machinery, automobiles, and pharmaceuticals. They serve as essential auxiliary equipment in industrial automation production lines.

If you would like to learn more about vibratory bowl feeders, you can refer to the following resources:

How to Select a Vibratory Feeder