In today’s fast-paced manufacturing environment, flexibility and efficiency are paramount. One of the most innovative solutions to achieve this is the flex feeding system. But what exactly is flex feeding, and how can it benefit your operations?

Understanding Flex Feeding

Flex feeding, or flexible part feeding, efficiently feeds or loads various parts into a manufacturing process. Unlike traditional feeding systems, which manufacturers typically design for specific components, a flex feeding system offers versatility, enabling them to handle a wide range of parts without needing constant adjustments or multiple systems.

Related reading(Please click on the following text)

Flexible feeder and spider gripper robot integration

Components of a Flex Feeding System

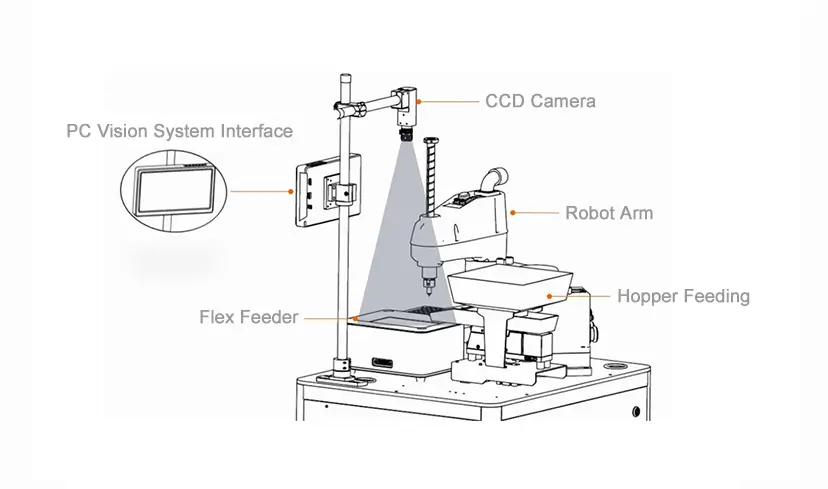

Three main components make up a flex feeding system:

- Flexible Feeder: This is the heart of the system. It feeds parts into the process in a controlled and consistent manner. What makes it “flexible” is its ability to adapt to different shapes, sizes, and types of components with minimal setup changes.

- Vision System: Integrated with advanced technologies like CCD cameras, the vision system helps the robot precisely locate the parts. This ensures that the system correctly positions each part for the next process stage, reducing errors and improving efficiency.

- Robot: The robot in a flex feeding system is responsible for picking and placing the parts into the correct positions. Combined with the vision system, the robot can handle a variety of parts with precision, making the entire operation smoother and more reliable.

Why Choose Flex Feeding?

- The real question is: does a flex feeding system make sense for your manufacturing needs? Here are a few reasons why it might:

- Versatility: If your production line requires handling various components, a flex feeding system is a game-changer. It eliminates the need for multiple feeders, saving time and reducing costs.

- Efficiency: With a flex feeding system, you can streamline your operations. Robotics and vision technology work together to handle parts with precision, reducing waste and downtime.

- Scalability: As your manufacturing needs grow, a flex feeding system can easily be scaled to accommodate new parts or increased production volumes. This adaptability makes it a future-proof investment.

In conclusion, flex feeding represents a significant leap forward in manufacturing technology. By combining flexibility, precision, and efficiency, it offers a robust solution for modern production challenges. Whether you’re looking to enhance your current operations or preparing for future growth, a flex feeding system might be the key to unlocking greater productivity and profitability.