In today’s fast-paced manufacturing world, efficiency and precision are non-negotiable. One key component that drives automation is the vibratory parts feeder. Whether you’re in automotive, medical equipment, or electronics, this tool is the unsung hero that ensures your production line runs like a well-oiled machine. But what exactly is it, and why is it so critical? Let’s dive into the details.

What is a Vibratory Parts Feeder?

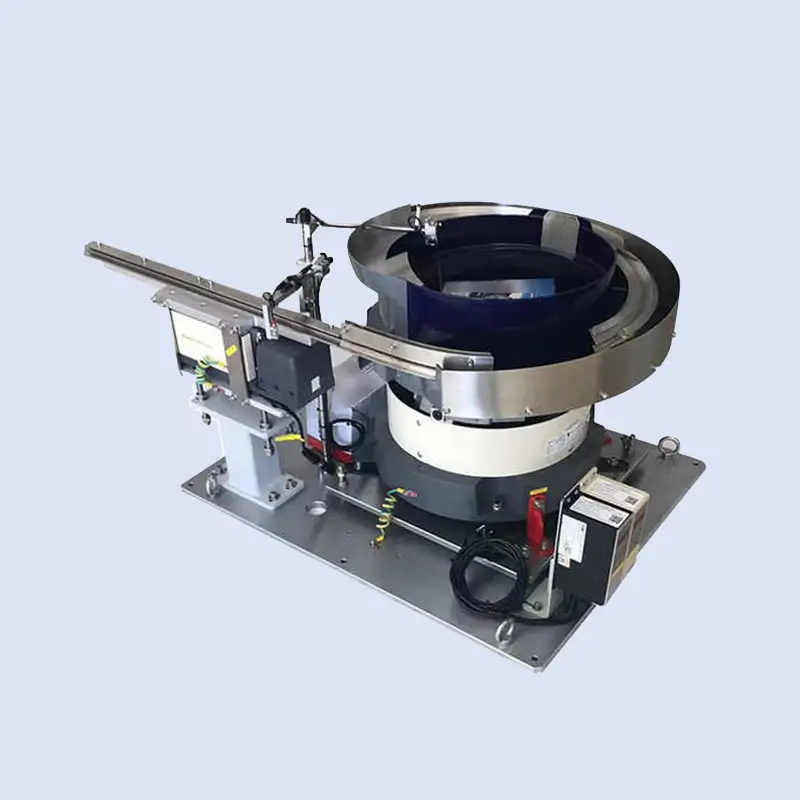

Vibratory parts feeders are automated systems designed to feed and orient parts seamlessly into production lines. Picture this: You’re assembling thousands of tiny screws or medical syringes. Manually aligning them would be a nightmare, right? That’s where vibratory feeders come in. They use controlled vibration to move parts into the right position—ready for assembly or packaging.

These systems are smart,and adaptable, and ensure that small, irregularly shaped components flow smoothly, saving you time and labor costs.

Why Are Vibratory Parts Feeders Essential in Modern Manufacturing?

Modern manufacturing relies on precision and speed. Vibratory parts feeders streamline production, ensuring parts are fed at a consistent rate with pinpoint accuracy. They replace manual labor, eliminate bottlenecks, and reduce downtime.

Think of them as the quiet workforce behind the scenes, tirelessly keeping production lines moving.

Key Benefits of Vibratory Parts Feeders

- Efficiency: Parts are fed quickly and consistently.

- Cost-effective: Reduces reliance on manual labor.

- Customizable: Can be tailored to handle different parts and materials.

- Low maintenance: Durable systems with minimal upkeep.

- Improved accuracy: Precisely aligns parts, reducing errors.

How Do Vibratory Parts Feeders Work?

At the heart of a vibratory feeder is controlled vibration. The process works as follows:

- A bowl feeder or inline feeder vibrates at a specific frequency.

- The vibration causes parts to move along a track.

- Parts are oriented and aligned as they progress.

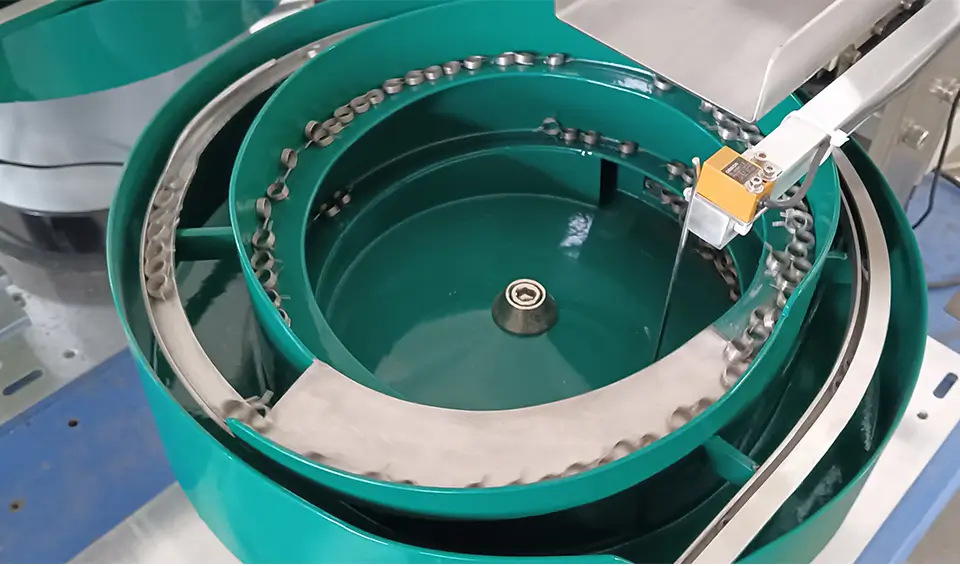

- Sensors or mechanical gates ensure only correctly positioned parts continue.

This controlled motion ensures the parts flow smoothly and consistently, even if they are irregularly shaped.

Types of Vibratory Parts Feeders

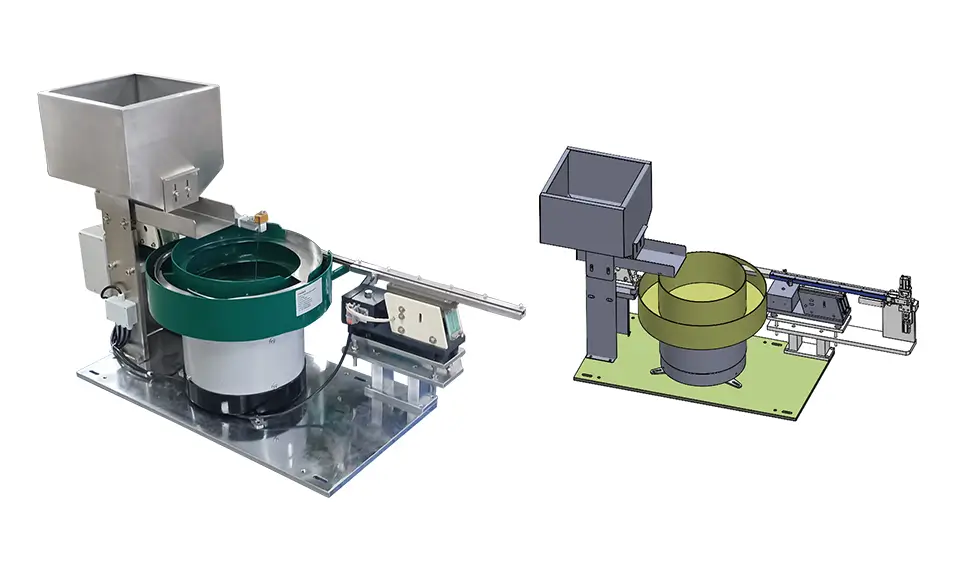

Not all vibratory feeders are the same. Here are the key types you’ll encounter:

1. Inline Vibratory Feeders

These feeders move parts in a straight line using vibration. They are ideal for systems requiring a consistent, linear part flow.

2. Bowl Feeders

Bowl feeders are circular and use vibrations to orient parts as they spiral upward. They are perfect for small, intricate parts that need precise positioning.

3. Centrifugal Feeders

Centrifugal feeders use spinning motion instead of vibration. They handle high-speed applications where parts need to be fed quickly and efficiently.

4. Step Feeders

Step feeders use a mechanical stepping motion to lift and position parts. They are quieter than vibratory feeders and ideal for noise-sensitive environments.

Key Industries Using Vibratory Parts Feeders

Automotive Manufacturing

In the automotive industry, vibratory parts feeders are essential for assembling components like nuts, bolts, and screws. They ensure high-speed, accurate part feeding for seamless assembly.

Electronics Assembly

Tiny electronic components, like chips or connectors, require precision. Vibratory feeders handle these delicate parts efficiently, preventing damage and errors.

Medical Equipment Manufacturing

From syringes to medical implants, vibratory feeders are vital in ensuring sterile, accurate part placement in medical manufacturing.

Pharmaceutical Industry

Pharmaceutical companies use vibratory feeders to sort and feed components like capsules, bottles, or droppers. They ensure hygiene and precision in every step.

Factors to Consider When Choosing a Vibratory Feeder System

Customization and Flexibility

Not all parts are created equal. Your feeder system must handle different shapes, sizes, and materials with ease.

Speed and Accuracy

Choose a system that matches your production speed without sacrificing precision.

Material Type

The material of your parts (metal, plastic, or glass) will determine the feeder’s design and vibration settings.

How to Maintain and Optimize Vibratory Feeders

Regular Cleaning and Lubrication

Keep your feeder clean to prevent debris from clogging the system. Regular lubrication ensures smooth operation.

Troubleshooting Common Issues

- Excessive noise: Check for loose components.

- Inconsistent feeding: Adjust vibration frequency or inspect for obstructions.

- Vibration failure: Verify the power supply and controller.

How Vibratory Feeder Manufacturers Like SWOER Lead the Market

Advanced Technology and Custom Solutions

Top manufacturers like SWOER use cutting-edge technology to deliver feeders tailored to your production needs. Whether it’s a complex part shape or high-speed requirement, they’ve got you covered.

Global Expertise and Service

With years of experience, SWOER offers reliable solutions and exceptional service. Their global reach ensures support wherever you operate.

Conclusion: Why Invest in Vibratory Parts Feeders?

Investing in a vibratory parts feeder is a game-changer for modern manufacturing. It boosts efficiency, reduces costs, and ensures precision—all critical factors in staying competitive. Whether you’re producing car parts, electronics, or medical devices, a reliable feeder system will transform your production line.