With rapid advancements in technology, the electronics manufacturing industry is evolving at an incredible pace. Consumers now demand more personalized and diverse products, while manufacturers face constant pressure to speed up production without compromising quality. To stay ahead, companies must embrace smarter, more efficient automation solutions.

That’s where flexible feeders come in. These advanced systems have revolutionized the way electronic components are sorted and positioned, making them a driving force behind industry progress.

Flexible Feeders Boosting Production Efficiency

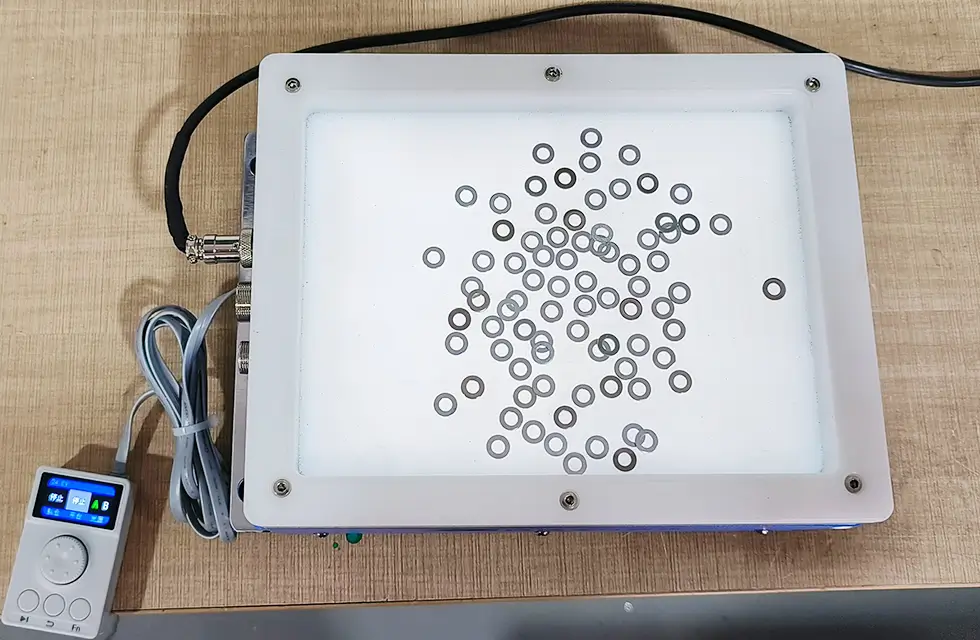

Flexible feeders use controlled vibrations to quickly sort and align components of various shapes and sizes—resistors, capacitors, transistors, and more. Instead of relying on manual sorting or rigid mechanical feeders, this technology adapts dynamically, optimizing workflow. The result? A faster production line with less downtime, increased throughput, and round-the-clock operation.

Flexible Feeding System Real-World Impact

Take a surface mount technology (SMT) production line, for example. A flexible feeder, working alongside an automatic placement machine, ensures precise positioning of microchips and other small components. This speeds up assembly minimizes human errors, and adapts seamlessly to different part types. Need to switch between batches? No problem—the system adjusts its vibration mode accordingly, making it perfect for high-mix, low-volume production.

Flexible Feeder Integrated with a Robot.

Flexible Part Feeder Cutting Down Manual Labor

Traditional sorting methods require significant manpower, making them slow, error-prone, and costly. A flexible feeder eliminates these inefficiencies with high-precision automation. By maintaining consistent output with minimal human intervention, manufacturers can reduce labor costs while improving process reliability.

Flexible Feeder System Ensuring Product Consistency

Consistency is key in electronics manufacturing. When every component is fed in a uniform manner, final products maintain higher quality standards. Flexible feeders help achieve this by ensuring parts are processed with precision, reducing defects, and enhancing overall reliability. This, in turn, strengthens a company’s competitive edge in the market.

The Future of Flexible Feeding Technology

As automation advances, flexible feeders will become even more versatile, extending their impact beyond electronics to industries like automotive, medical devices, and precision engineering. Their ability to handle complex, high-speed production demands makes them an essential tool for manufacturers looking to stay ahead in an ever-changing market.

Flexible feeders aren’t just improving efficiency—they’re shaping the future of smart manufacturing.

Contact Swoer

Contact Swoer to get the design of Flexible feeder integrated with a robot.