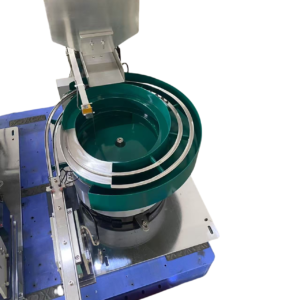

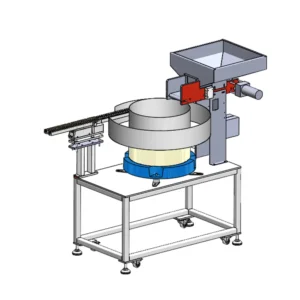

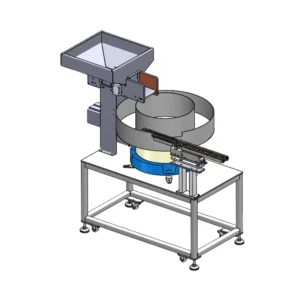

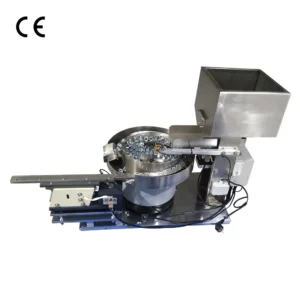

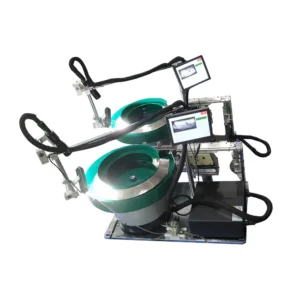

Handling springs in industrial automation presents unique challenges. Springs vary in shape and size, making their feeding a complex task. At SWOER, we offer advanced solutions for these specific needs.

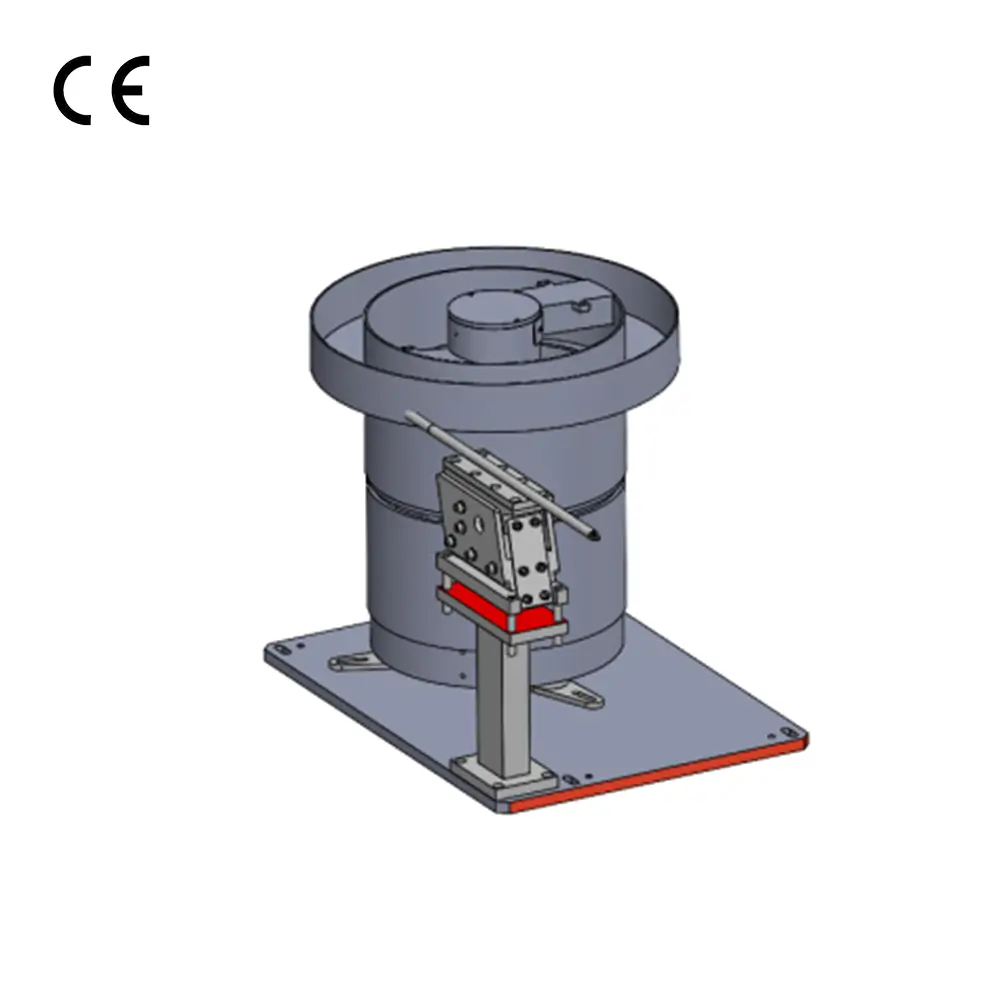

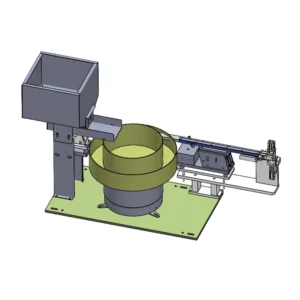

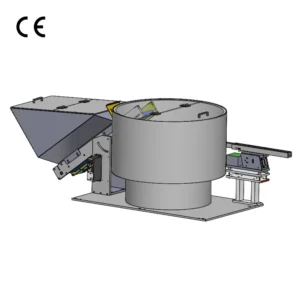

Bowl Feeder Parameter:

| Product Name | Part Feeding Systems for Springs |

| Material | SUS201/304 |

| Material Speciality | Cold treatment forging alloy, High strength, High hardness |

| Voltage | 220V |

| Power | 65W /150W /180W / 220W / 350W |

| Authentication | CE, ROHS, ISO9001 |

| Warranty | 1 year warranty |

| MOQ | 1 set |

| Lead Time | 10-14 days |

| Payment Term | T/T 40% Deposit and balance before shipment |

| Original of Place | China |

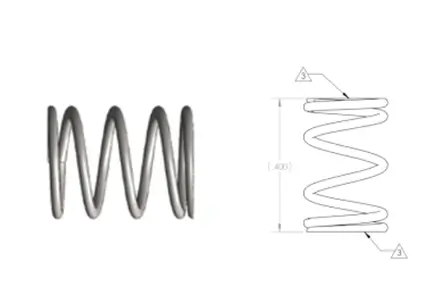

Springs Details:

Challenges of Feeding Springs

Springs, whether compression, extension, or torsion, pose several issues:

- Variability: Springs come in different diameters, lengths, and coil configurations, complicating the feeding process.

- Tangle and Overlap: Springs can easily tangle or overlap, causing blockages and downtime.

- Delicate Handling: Springs are delicate and improper handling can deform them, leading to defects.

Are you looking for a reliable spring feeder?

SWOER offers custom-designed bowl feeders to meet your exact needs. Our machines are CE & UL certified, ensuring safety and quality.

Benefits of our spring bowl feeders:

- Increased efficiency: Feed thousands of parts per hour

- Customizable: Tailored to your specific parts and production line

- Reliable: Built to last and maintain consistent performance

- Fast delivery: Get your machine quickly

- Safety certified: CE & UL certified for your peace of mind

Our experienced engineering team will work with you to design a solution that meets your specific requirements. Whether you need to feed small or large springs, we have the expertise to handle your project.

Don’t wait! Contact us today to request a quote and learn more about how our spring bowl feeders can benefit your business.

Reviews

There are no reviews yet.