Information and Testing Requirements

This is a necessary condition to ensure that the vibration feeder can successfully meet the customer’s on-site application.

1. Clear customer needs

Before production, the following information must be clarified:

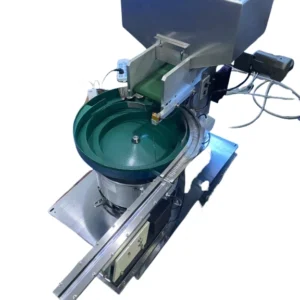

Target efficiency: refers to the quantity of materials delivered per unit time (pieces/minute).

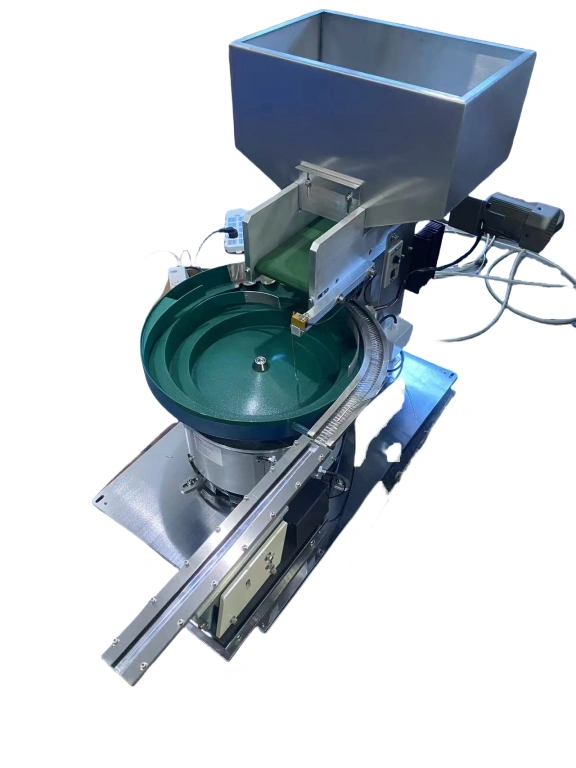

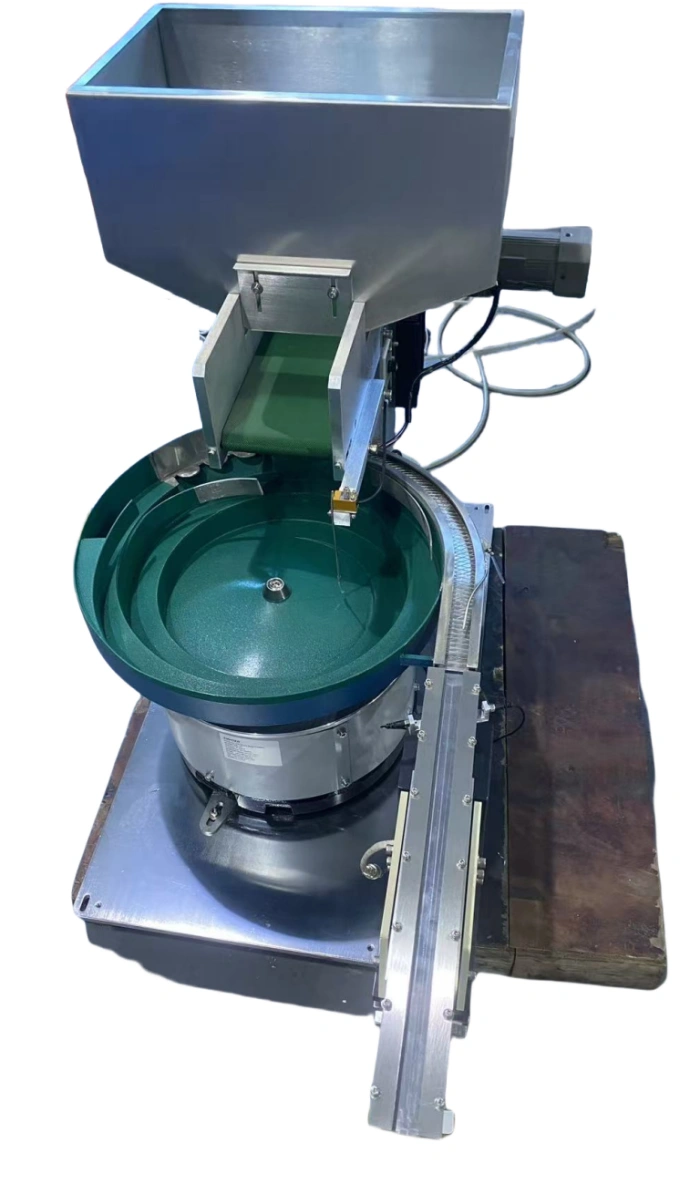

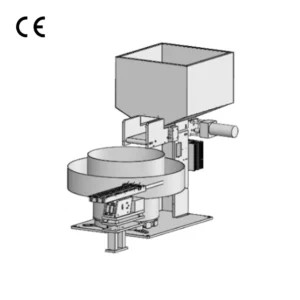

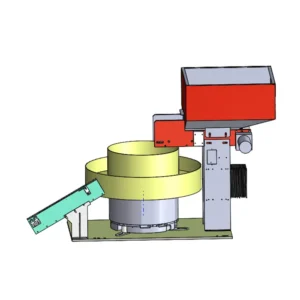

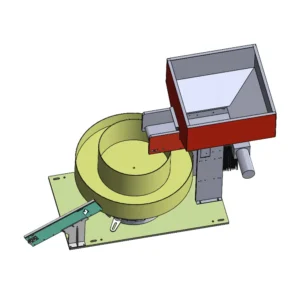

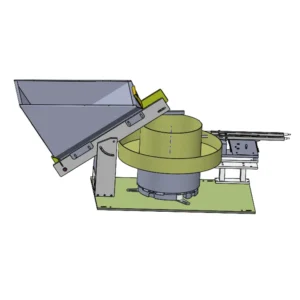

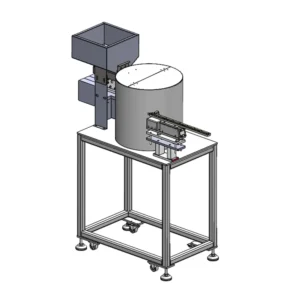

Space limitation: The maximum allowable space (diameter, height) for installing the vibration feeder.

Supporting equipment: What type of downstream equipment (such as robotic arms, assembly machines) is connected to, and what is the interface form.

Special requirements: such as cleanroom rating, explosion-proof, food grade, low noise, etc.

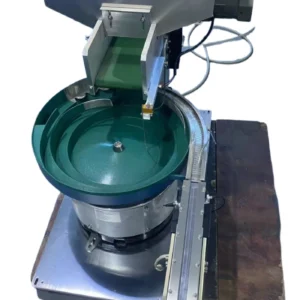

2. Strict sample testing

The final version of the parts sample provided by the customer must be used for testing and debugging! Using samples from different batches or with slight differences may result in on-site failure.

Durability testing: requires long-term operation, simulating the real production rhythm, testing its stability and reliability, ensuring no material jamming and efficiency degradation.

3. Documents and after-sales service

Operation and Maintenance Manual: Provides clear debugging guidelines and daily maintenance instructions.

Spare parts support: Provide replacement support for vulnerable parts such as shrapnel and electromagnets.

Recenze

Zatím zde nejsou žádné recenze.