What Role Does CCD Vision System Play in Parts Feeding and Conveying?

Revolutionize part feeding with CCD Vision Systems for enhanced precision and efficiency.

Leverage the power of CCD Vision Systems to streamline your part-feeding operations. These advanced systems integrate with vibratory and flexible feeders, ensuring accurate part orientation, rejection of defective parts, and optimized feeding rates. Experience the benefits of enhanced precision, reduced waste, and improved productivity with CCD Vision Systems.

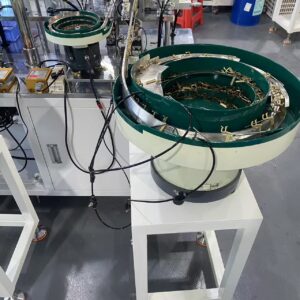

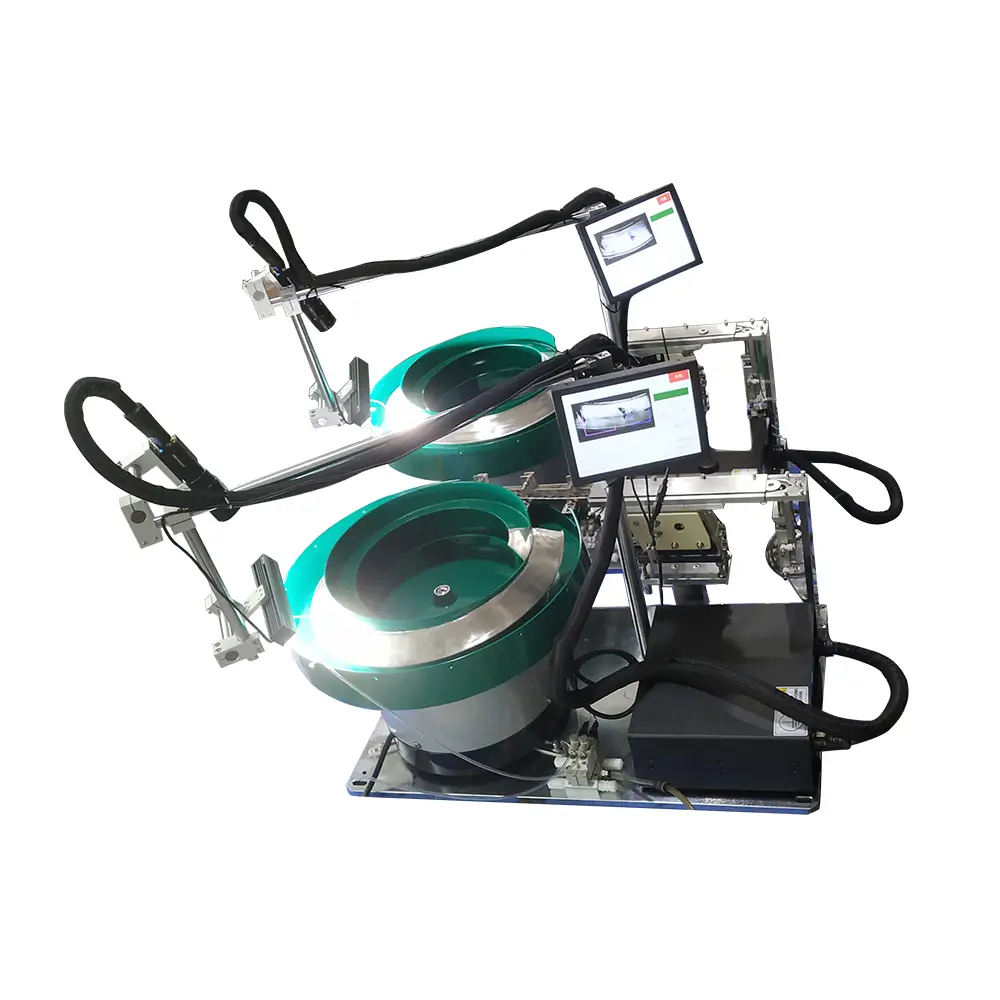

Swoer Hot-Sale CCD Vision Systems

Application of CCD Vision System in Parts Feeding and Conveying

Key benefits of CCD Vision Systems for vibratory feeders

- Enhanced part orientation: Ensure consistent part orientation for downstream processes.

- Defect detection and rejection: Eliminate defective parts from the feeding process, minimizing rework and scrap.

- Optimized feeding rates: Optimize feeding rates to match production demands, preventing bottlenecks and part jams.

- Improved process reliability: Enhance overall process reliability and consistency.

- Reduced waste and costs: Minimize material waste and associated costs.

Key Benefits of CCD Vision Systems for Flex Feeders

Precise part singulation: CCD systems can accurately separate tangled or overlapping parts in a flexible feeder, ensuring only one part is available for pick-up.

Enhanced flexibility: Vision systems allow for quick changeovers between different part types by simply adjusting the inspection criteria.

Improved part handling for complex shapes: CCD cameras can handle parts with intricate geometries that might be difficult to orient with traditional vibratory feeder designs.

Reduced reliance on mechanical adjustments: Vision systems can compensate for minor variations in part size or orientation, minimizing the need for frequent mechanical adjustments to the feeder track.