Outline

- What are Centrifugal Feeders?

- Importance of Centrifugal Feeders in Industrial Automation

- Evolution and Applications of Centrifugal Feeders

- The Mechanics Behind Centrifugal Feeder Functionality

- Key Components of a Centrifugal Feeder System

- How Centrifugal Feeders Handle and Orient Parts

- Principles Guiding Centrifugal Feeder Design

- Different Types of Centrifugal Feeder Designs

- Enhancements and Innovations in Modern Centrifugal Feeder Design

- What are the advantages of using centrifugal feeders over other feeding systems?

- How do centrifugal feeders handle different types and sizes of parts?

- What are the typical maintenance requirements for centrifugal feeders?

- How does Swoer ensure quality and reliability in their centrifugal feeder products?

Introduction to Centrifugal Feeders

What are Centrifugal Feeders?

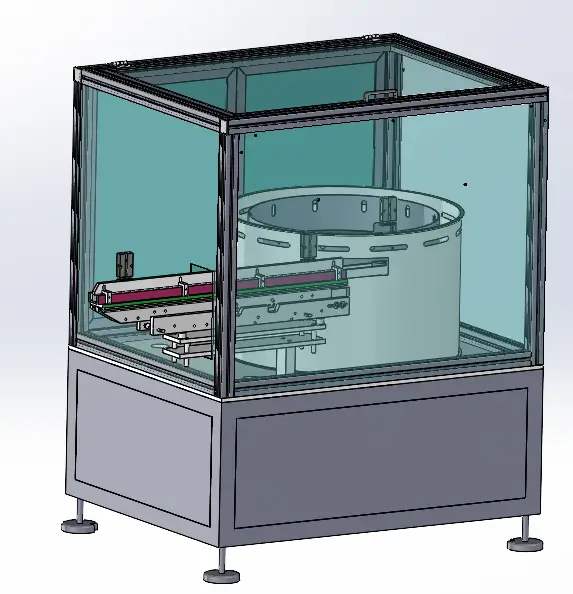

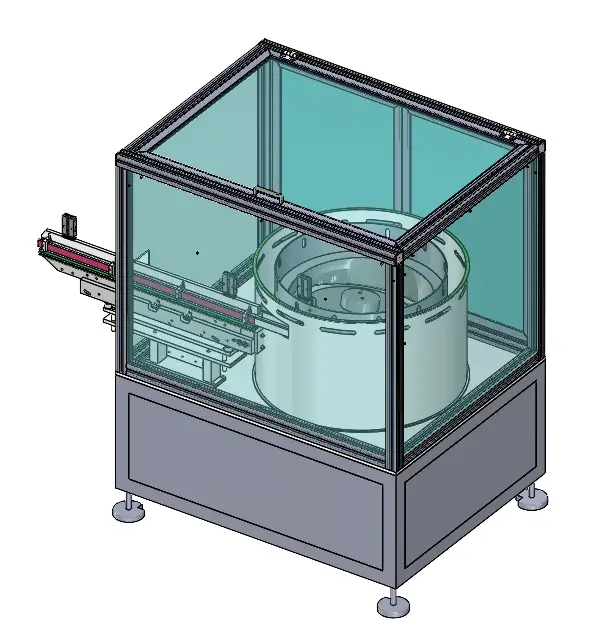

Centrifugal feeders are automation equipment that utilizes centrifugal force and custom tooling to align bulk, randomly oriented parts, ensuring a consistent supply of correctly positioned parts for downstream processes.

It consists of a bowl-shaped container, typically made of stainless steel or plastic, with an inclined spiral track inside. The feeder loads parts into the center of the bowl and uses centrifugal force to move them along the spiral track toward the bowl’s outer edge. As the parts move along the track, the feeder orients them in a specific direction, preparing them for further processing or assembly.

Importance of Centrifugal Feeders in Industrial Automation

Centrifugal feeders play a crucial role in modern industrial automation by optimizing production lines and enhancing efficiency. Industries such as automotive, electronics, pharmaceuticals, and packaging rely heavily on these feeders, as they ensure precise part orientation, which is essential for assembly, inspection, and packaging processes. By automating the feeding and orientation of parts, centrifugal feeders actively minimize manual labor, reduce cycle times, and significantly improve overall productivity.

Evolution and Applications of Centrifugal Feeders

Centrifugal feeders have evolved significantly since their inception, with advancements in design, technology, and materials leading to greater efficiency and versatility. Initially used primarily for small, lightweight parts, centrifugal feeders now handle a wide range of part sizes, shapes, and materials. Their applications span across various industries, including automotive assembly lines, electronics manufacturing, medical device production, and consumer goods packaging.

Exploring Centrifugal Feeder Operation

The Mechanics Behind Centrifugal Feeder Functionality

The operation of a centrifugal feeder relies on the principles of centrifugal force and friction. As parts enter the feeder bowl, the feeder uses centrifugal force to carry them along the spiral track, pushing them outward toward the feeder’s perimeter. Along the track, frictional forces regulate their speed and orientation, ensuring they align properly for downstream processes.

Key Components of a Centrifugal Feeder System

A typical centrifugal feeder system consists of several essential components, including the feeder bowl, feeder base, drive unit, and control system. The feeder bowl, usually made of stainless steel or plastic, holds and orients the parts, while the feeder base provides support and stability. The drive unit generates the rotational motion that propels parts along the spiral track, while the control system regulates the feeder’s speed, direction, and operation.

How Centrifugal Feeders Handle and Orient Parts

Centrifugal feeders are capable of handling a wide variety of parts, including screws, nuts, bolts, washers, electronic components, and more. They can accommodate different part sizes and shapes by adjusting the feeder bowl’s geometry and track configuration. By precisely controlling rotational speed and track design, centrifugal feeders ensure that they correctly orient the parts before discharging them for further processing.

Centrifugal Feeder Design: Innovation and Efficiency

Principles Guiding Centrifugal Feeder Design

The design of centrifugal feeders is guided by principles of efficiency, reliability, and ease of use. Engineers strive to optimize the feeder bowl’s geometry, track configuration, and material selection to achieve smooth and consistent part handling. Attention is also given to minimizing maintenance requirements and maximizing uptime to enhance overall operational efficiency.

Different Types of Centrifugal Feeder Designs

Centrifugal feeders come in various designs to accommodate different part sizes, shapes, and application requirements. Common variations include single-lane and multi-lane feeders, as well as custom-designed feeders tailored to specific part geometries or production processes. Each design offers unique advantages in terms of throughput, flexibility, and precision.

Enhancements and Innovations in Modern Centrifugal Feeder Design

Recent advancements in centrifugal feeder design have focused on improving speed, accuracy, and adaptability. Features such as quick-change tooling, adjustable track settings, and integrated sensors for part detection and tracking have enhanced feeder performance and versatility. Additionally, advancements in materials and manufacturing techniques have resulted in feeder systems that are more durable, corrosion-resistant, and hygienic.

Common Questions About Centrifugal Feeders

What are the advantages of using centrifugal feeders over other feeding systems?

Centrifugal feeders offer several advantages over alternative feeding systems, including high-speed operation, precise part orientation, and the ability to handle a wide range of part sizes and shapes. They also remain relatively compact and integrate easily into existing production lines, making them ideal for applications where space is limited.

How do centrifugal feeders handle different types and sizes of parts?

Centrifugal feeders utilize adjustable track settings and bowl geometries to accommodate different part sizes and shapes. By fine-tuning the feeder’s rotational speed and track configuration, operators can ensure that they properly orient and convey parts without jamming or misalignment.

What are the typical maintenance requirements for centrifugal feeders?

Routine maintenance for centrifugal feeders typically involves cleaning, lubrication, and inspection of key components such as the feeder bowl, track, and drive unit. We recommend conducting regular checks for wear and tear, loose fasteners, and electrical connections to prevent downtime and ensure optimal performance.

How does Swoer ensure the quality and reliability of its centrifugal feeder products?

Swoer employs strict quality control measures throughout the manufacturing process to ensure that its centrifugal feeder products meet the highest performance and reliability standards. This includes the use of high-quality materials, precision machining techniques and thorough testing procedures to verify product integrity and functionality (all raw materials have CE certification). In addition, Swoer offers comprehensive customer support services to assist with the installation, operation and maintenance of its centrifugal feed line systems.