- Introduction

- What is a Vibratory Parts Feeding System?

- Key Components of a Vibratory Parts Feeding System

- Vibratory Drive Unit

- Vibratory Feeder Bowl

- Amplitude Controller

- Inline Feeder and Track

- Escapement or Parts Nest

- Types of Vibratory Bowl Feeders

- Cast Aluminum Bowl Feeders

- Stainless Steel Bowl Feeders

- Applications of Vibratory Parts Feeding Systems

- Automotive Manufacturing

- Electronics Manufacturing

- Medical Devices

- Pharmaceuticals

- Vibratory Feeder Service and Maintenance

- Evaluation and Repairs

- Fast Turnaround

- DIY Maintenance

- Benefits of Using Vibratory Parts Feeding Systems

- Increased Efficiency

- Consistency

- Customization

- Reduced Labor Costs

- Conclusion

Introduction

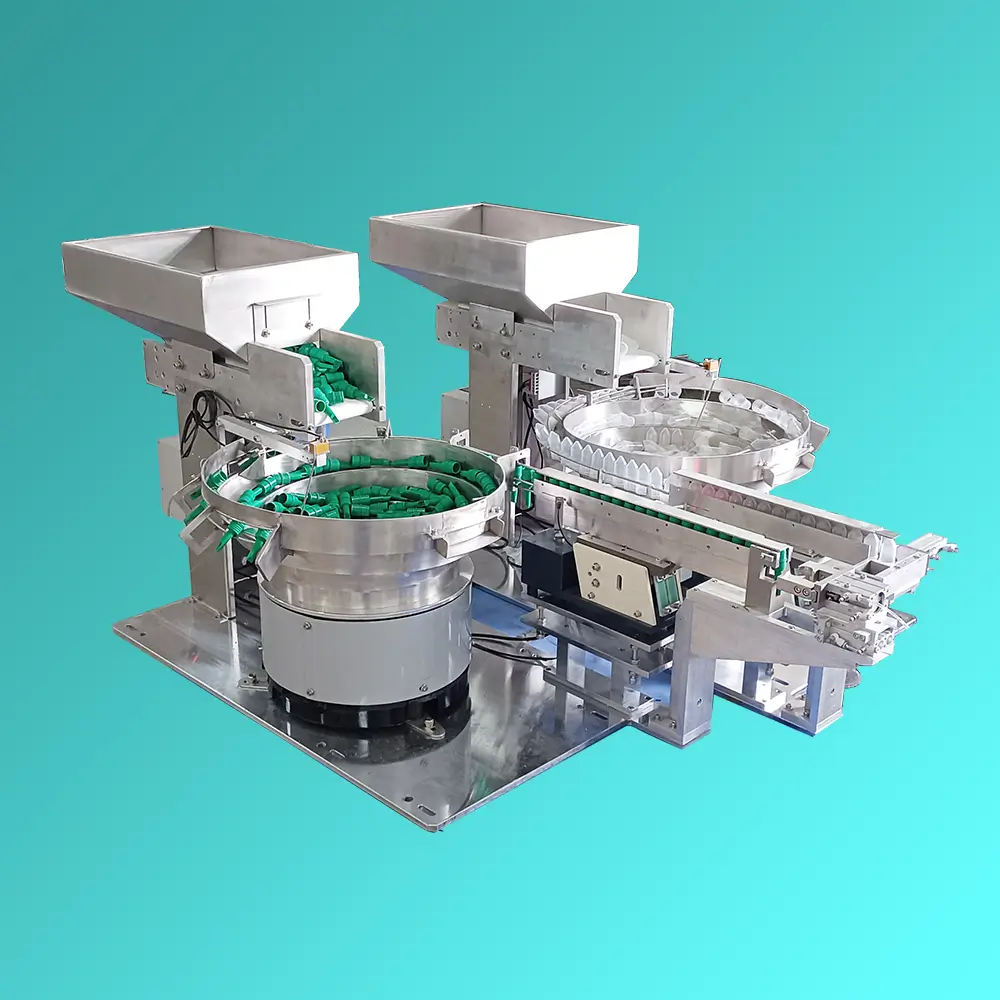

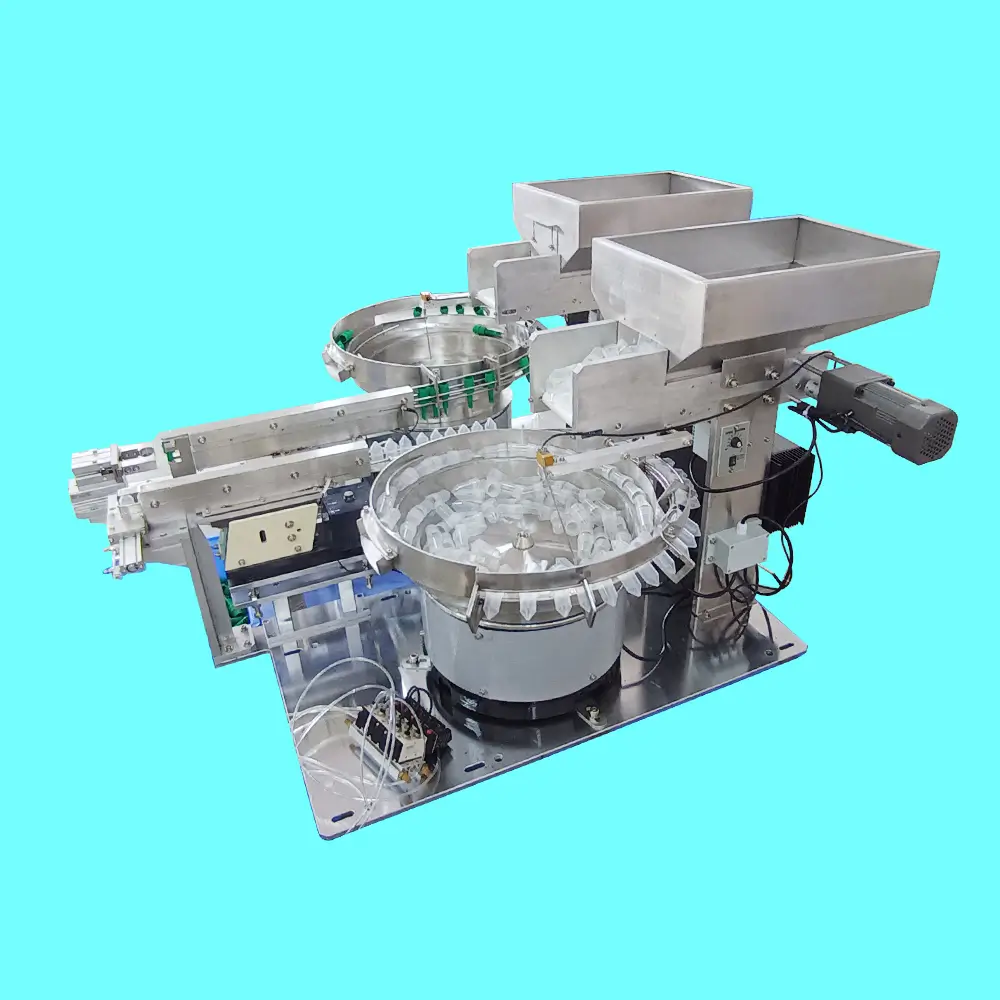

Vibratory parts feeding systems are essential to modern automation, as they offer a reliable and efficient way to orient, feed, and deliver components in various industries. Furthermore, whether you’re involved in automotive manufacturing, electronics, or medical device production, gaining a deeper understanding of the components and functionality of a vibratory parts feeder can significantly enhance your production line. Therefore, in this article, we will take a closer look at vibratory parts feeding systems, exploring their key components, different types, and various applications. Additionally, we will discuss the services available to ensure they continue running smoothly.

What Are Vibratory Parts Feeding Systems?

Vibratory parts feeding systems play a crucial role in automating the process of handling, orienting, and feeding parts along a production line. More specifically, these systems typically consist of several key components. For instance, a vibratory feeder ensures smooth movement, while a hopper stores additional parts to maintain a continuous flow. In addition, sensors help detect and regulate the feeding process, ensuring precision and efficiency. Moreover, a sturdy feeder stand provides the necessary support and stability, allowing the entire system to function seamlessly.

Manufacturers design vibratory parts feeders to provide a steady flow of parts in a consistent and organized manner. These systems reduce the need for manual handling and increase the speed and efficiency of operations, making them an invaluable tool in high-volume manufacturing environments.

Key Components of a Vibratory Parts Feeding System

A typical vibratory parts feeding system includes several core components, each of which plays a crucial role in ensuring smooth operation:

Vibratory Drive Unit: Powers the feeder and provides the vibration necessary to move the parts.

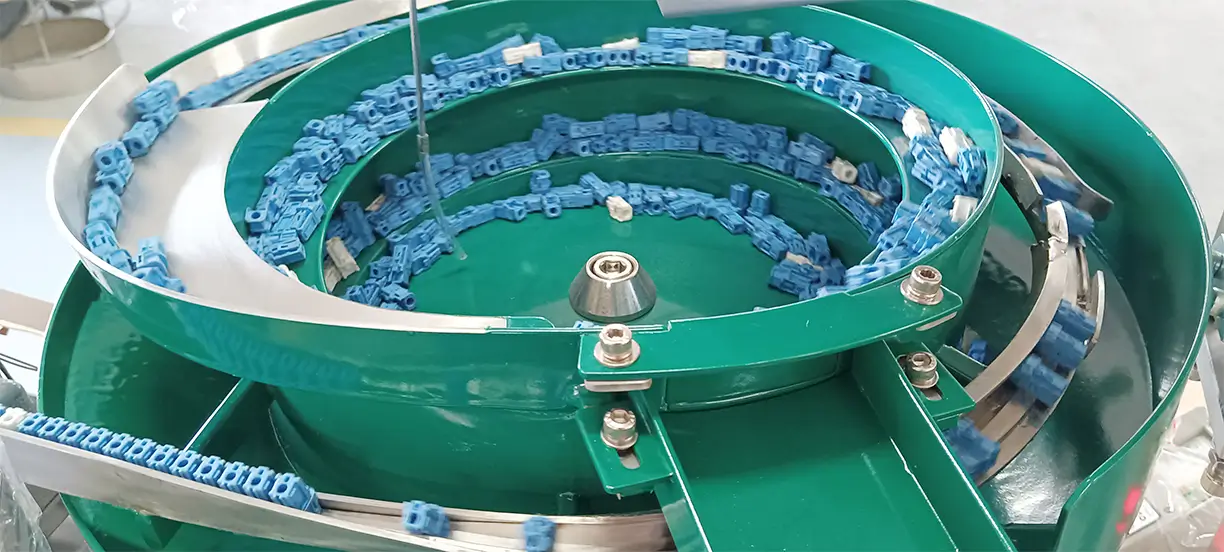

- Vibratory Feeder Bowl: This bowl efficiently orients and guides parts to the next production stage. Specifically, it may use a tool-free design for flexibility or custom tooling for precise part requirements.

- Amplitude Controller: This controls the intensity of the vibrations, adjusting the flow of parts.

- Inline Feeder and Track: These elements guide the parts along their path from the bowl feeder to the next step in the production process.

- Escapement or Parts Nest: Used to release the parts into the assembly process, ensuring the right orientation and position.

These components work together to ensure that parts are fed efficiently and consistently, with minimal manual intervention required.

Types of Vibratory Bowl Feeders

Vibratory bowl feeders are available in different materials and configurations, each suited to specific needs:

- Cast Aluminum Bowl Feeders: These types of Vibratory Bowl Feeders are highly durable and well-suited for handling medium-weight parts. They are ideal for environments that require high throughput and long-term reliability.

- Stainless Steel Bowl Feeders: As a result, these feeders not only resist corrosion more effectively but also meet the stringent hygiene and sanitation standards required in certain industries. Specifically, they are ideal for sectors such as food processing, pharmaceuticals, and medical device manufacturing, where cleanliness and durability are essential.

Ultimately, both types deliver exceptional performance. However, more importantly, when deciding between them, you should carefully consider the application’s specific requirements. For instance, factors such as the type of parts being handled, the operating environment, and overall system efficiency play a crucial role in making the right choice.

Applications of Vibratory Parts Feeding Systems

For this reason, many industries rely on vibratory parts feeding systems due to their versatility and efficiency. More specifically, these systems are widely used in various applications, including:

- Automotive Manufacturing: Vibratory feeders are used to handle small parts like bolts, screws, and nuts, ensuring they are fed into automated assembly lines in the correct orientation.

- Electronics Manufacturing: More specifically, these systems are particularly well-suited for feeding delicate components, such as capacitors, resistors, and connectors, into automated machines. In addition, they ensure precise positioning and handling, which is essential for maintaining accuracy and efficiency in the assembly process.

- Medical Devices: Vibratory feeders are used to orient and feed small parts for medical device assembly, ensuring consistent quality and reliability.

- Pharmaceuticals: In the pharmaceutical industry, vibratory parts feeders help feed tablets, capsules, and other small parts into packaging and labeling machines.

Moreover, these systems not only help increase throughput but also play a crucial role in reducing errors and enhancing overall production efficiency. As a result, they contribute to smoother operations, higher product quality, and greater cost-effectiveness in manufacturing processes.

Vibratory Feeder Service and Maintenance

Proper maintenance is absolutely essential to ensuring that your vibratory feeding system continues to operate at peak efficiency. In addition, regular upkeep helps to extend the lifespan of the system, reducing the likelihood of unexpected failures. Many manufacturers, including ADI, offer comprehensive repair services for all types of vibratory feeders, regardless of the original manufacturer. Furthermore, these services are designed to restore your system to optimal performance, ensuring that it meets the necessary operational standards. By investing in proper maintenance and repair, you can avoid costly downtime and improve overall productivity.

Services Include:

- Evaluation and Repairs: A nominal fee is typically charged for evaluating the condition of a feeder. Once the issue is diagnosed, repairs are quoted, and customers are informed before work begins.

- Fast Turnaround: Basic repairs on feeder units are usually completed within three working days, while more complex repairs on bowl tooling may take longer.

- DIY Maintenance: In some cases, customers may be advised on how to make simple repairs or adjustments to their tooling, allowing them to minimize downtime and keep production running smoothly.

Regular servicing ensures that vibratory feeders continue to perform reliably, helping businesses avoid costly disruptions in production.

Benefits of Using Vibratory Parts Feeding Systems

Vibratory parts feeders offer several advantages that make them an attractive option for businesses looking to improve their automation processes:

- Increased Efficiency: By automating the feeding process, vibratory feeders eliminate the need for manual handling, increasing throughput and reducing the chances of errors.

- Consistency: Vibratory feeders provide a reliable and consistent flow of parts, helping to ensure that each part is fed in the correct orientation every time.

- Customization: Vibratory feeders can be customized to handle a wide range of part sizes and shapes, making them suitable for a variety of industries.

- Reduced Labor Costs: Automation reduces the need for manual labor, allowing businesses to allocate resources to more value-added tasks.

With these benefits, vibratory parts feeders can help businesses achieve higher productivity and lower operational costs.

Conclusion

Vibratory parts feeding systems are a critical component in many automation processes, offering a reliable and efficient solution for feeding and orienting parts. From cast aluminum to stainless steel bowl feeders, these systems are adaptable to a variety of industries and applications. Regular maintenance and repair services help ensure that your system continues to operate at peak performance, keeping your production lines running smoothly. Whether you’re in automotive, electronics, medical devices, or pharmaceuticals, investing in a high-quality vibratory feeding system can greatly enhance the efficiency and consistency of your manufacturing process. Moreover, such a system can significantly streamline your operations, reducing the need for manual intervention. As a result, it not only improves production speed but also minimizes the risk of errors, leading to higher product quality. Additionally, the reliability of a well-designed vibratory feeder ensures that your processes remain uninterrupted, contributing to long-term operational success. Ultimately, this investment pays off by boosting both productivity and cost-effectiveness.