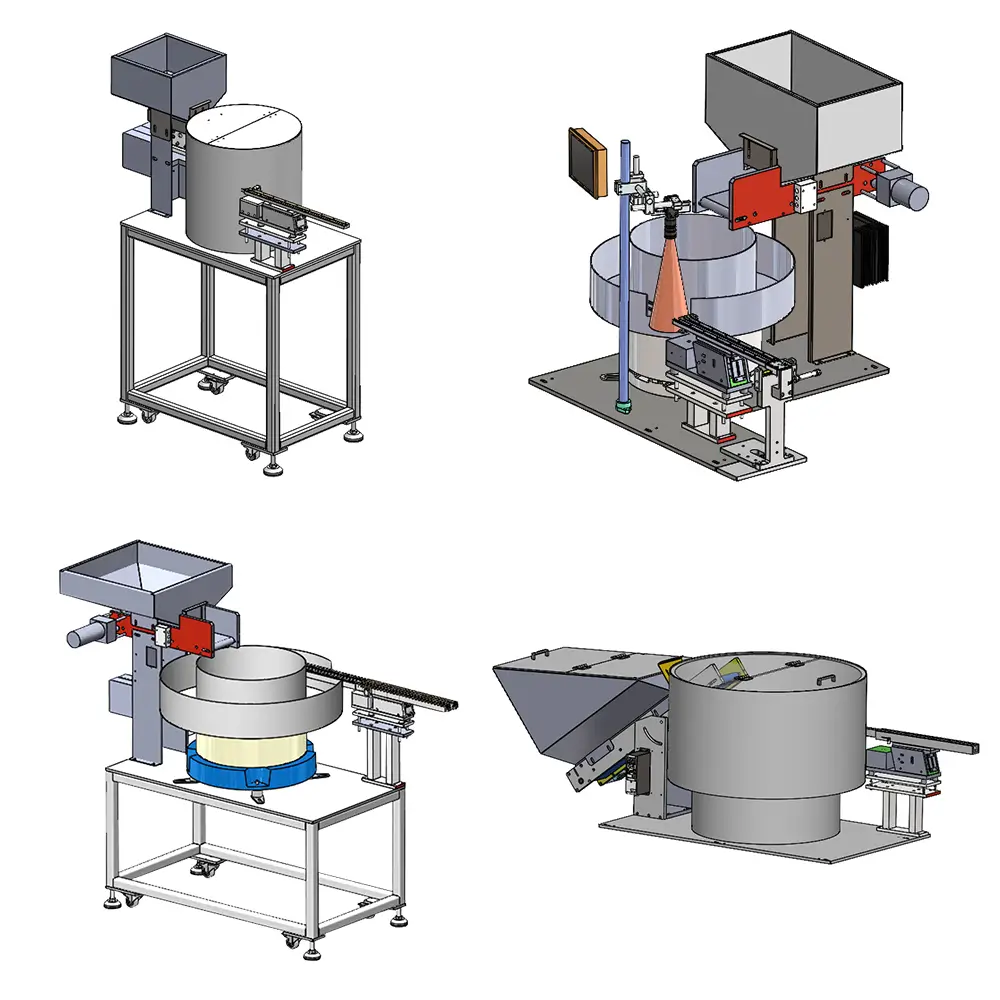

Electronics manufacturing demands precision at every step. As products get smaller and more complex, every component must be handled with care and accuracy. That’s where bowl feeder automation comes in. Vibratory bowl feeders play a crucial role in automatically sorting and feeding electronic parts, ensuring they enter the assembly line in the right position. A well-designed bowl feeder system makes all the difference.

Customizing the Track for Different Components

Not all electronic components are the same. Resistors, capacitors, and transistors vary in shape, size, and fragility, so their bowl feeder systems need custom-designed tracks. The track must guide parts smoothly without jams, damage, or unnecessary friction. For instance, soft coatings or special materials can help reduce surface wear when handling delicate ceramic capacitors. A poorly designed track could slow production or increase waste—neither is ideal.

Optimizing Vibration for Efficiency

The right vibration settings ensure efficiency. A vibratory parts feeder needs precise frequency and amplitude to match the size and weight of the components. Small, lightweight parts don’t need much force, while larger or heavier ones require more energy to keep moving. Getting these parameters right means fine-tuning factors like spring stiffness and motor power. When done correctly, the system runs smoothly, reducing errors and improving output.

Smart Systems for Better Performance

Modern bowl feeder systems go beyond simple vibration. Many now include intelligent control features that adjust vibration frequency based on real-time feedback. This keeps feeding rates steady and prevents blockages. Some even integrate vision inspection, allowing the system to detect and remove defective parts before they reach the next stage. Take SWOER’s vibratory bowl feeder, for example – it combines automation with a vision inspection system that detects breaks, breakages, and deformations to improve accuracy and reduce waste.

Clean and Reliable Operation

Cleanliness matters, especially in electronics manufacturing. Dust or contaminants can cause defects, so high-end bowl feeder automation solutions often feature enclosed structures and built-in air purification. This prevents unwanted particles from interfering with sensitive components.

Video

The Bottom Line

A well-designed vibratory feeder doesn’t just improve efficiency—it cuts costs, reduces errors, and keeps production running smoothly. In a fast-moving industry where precision is everything, the right bowl feeder system gives manufacturers a competitive edge.

Contact Swoer

Contact Swoer team for custom vibratory feeder design.