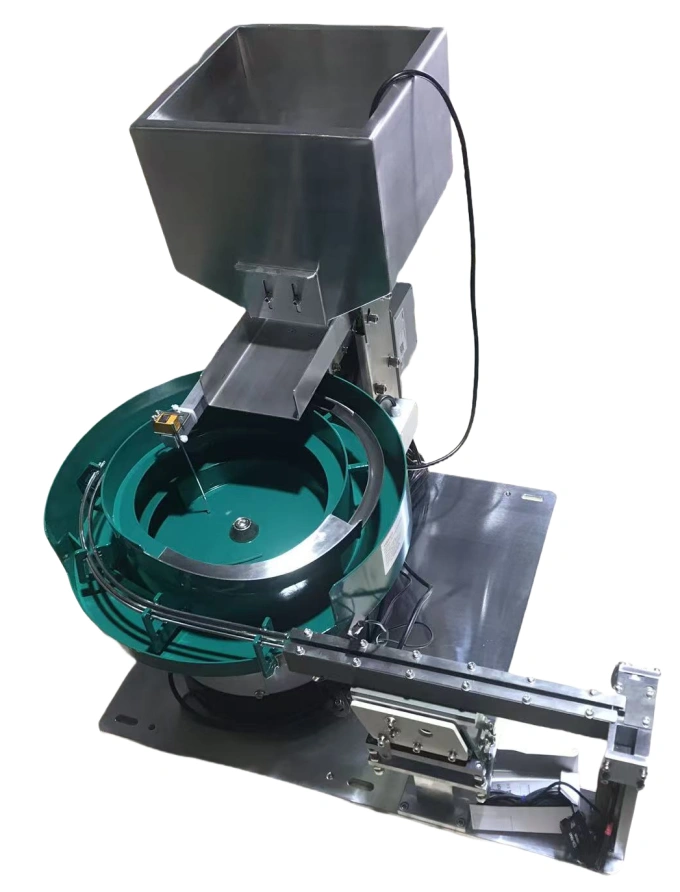

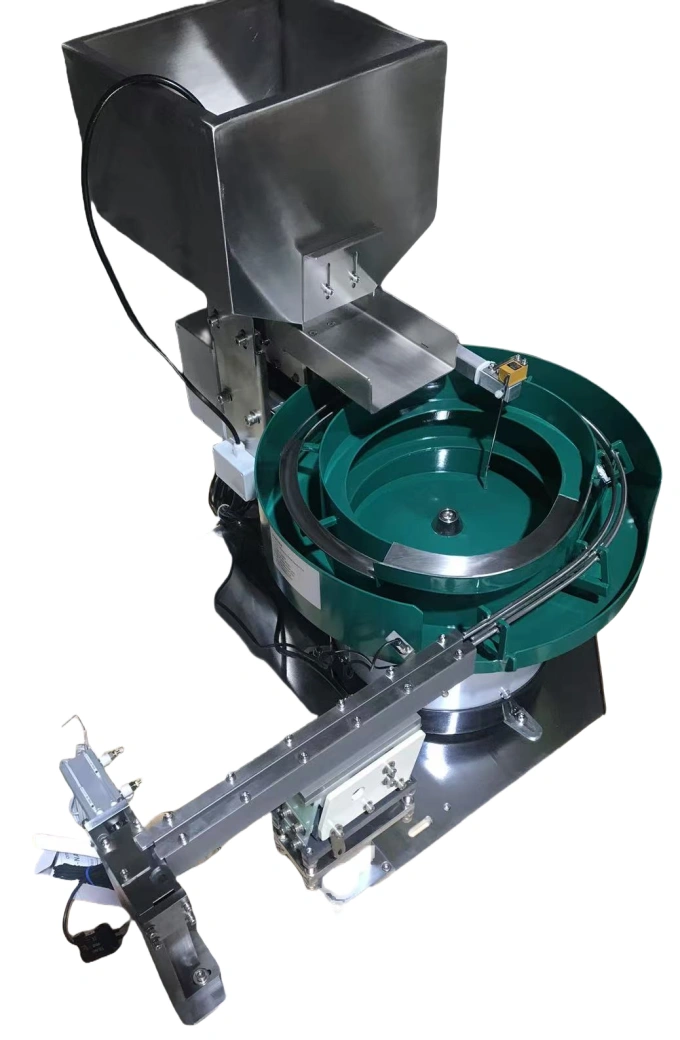

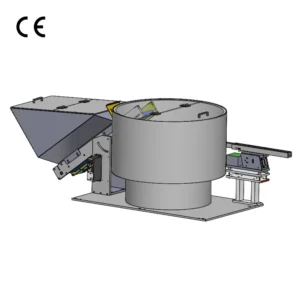

Adding a camera to a vibratory bowl equips it with “eyes” and a “brain,” transforming it from a simple sorting and feeding device into an intelligent inspection and positioning system.

- Precise Orientation Recognition and Positioning

- Sự miêu tả: The camera quickly captures an image of each part at the bowl’s discharge outlet. Image processing software then precisely identifies the part’s posture, such as front/back side, angle, and rotational direction.

- Use: Solves the challenge where traditional bowls cannot achieve 100% correct orientation for parts with very similar features or extremely critical orientation requirements.

- Real-Time Quality Inspection and Defective Product Ejection

- Sự miêu tả: The vision system is pre-programmed with parameters of a standard part (e.g., dimensions, shape, color, presence of flaws). As parts pass by, the system compares them to this master template.

- Use:

- Dimensional Defects: Detecting if a part is oversized, undersized, or has burrs.

- Cosmetic Defects: Identifying scratches, dents, rust spots, or contamination.

- Assembly Completeness: Checking for missing features, e.g., insufficient plastic injection or a missing washer on a screw.

- Mixed Parts Detection: Identifying if parts of a different model have been mixed in.

- Action: Upon detecting a defective part, the system immediately signals a rejection device (e.g., air blast nozzle, pusher) to remove it from the production line.

- Precise Positioning for Robot Picking

- Sự miêu tả: This is the most advanced application. The camera not only identifies the part’s orientation but also calculates its precise coordinates (X, Y) and rotation angle (θ) within a coordinate system. This data is sent in real-time to a downstream robotic arm.

- Use: Solves the problem of inaccurate “blind picking” by robots. It enables high-precision picking and placing, significantly enhancing the accuracy and reliability of automated assembly.

- Data Recording and Traceability

- Sự miêu tả: The system can record production counts, good part counts, defective part counts, and types of defects.

Use: Provides data support for production management and process improvement, enabling product quality traceability.

Đánh giá

Hiện tại không có đánh giá nào.