Your Reliable Flex Feeder Manufacturer

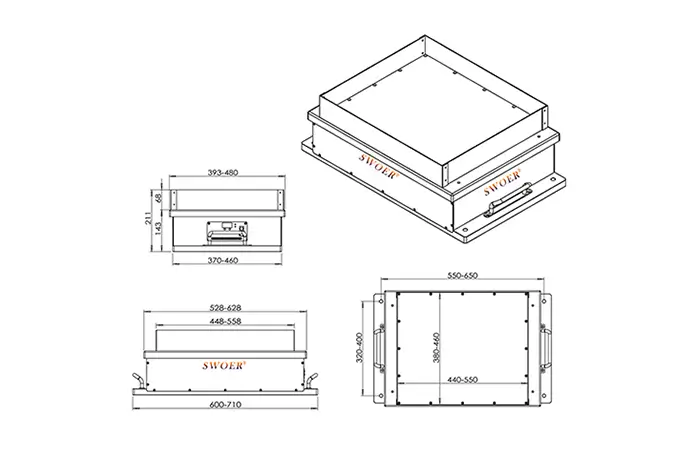

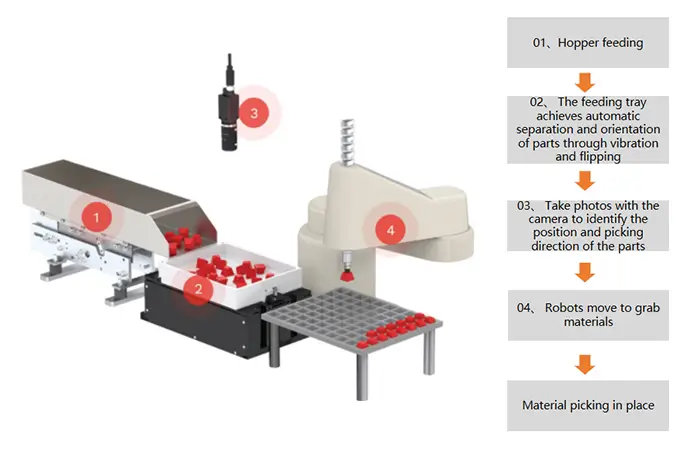

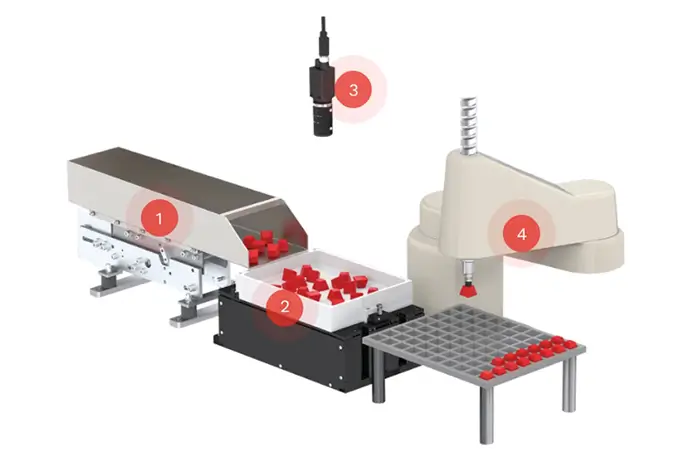

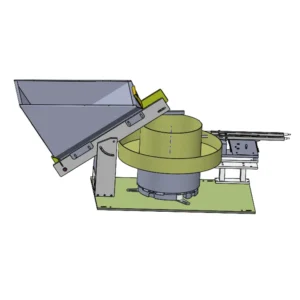

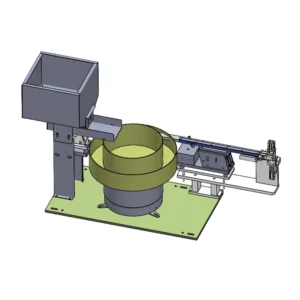

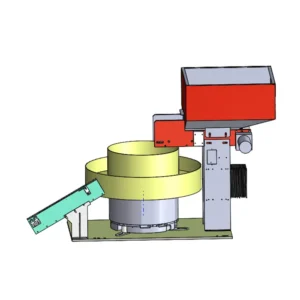

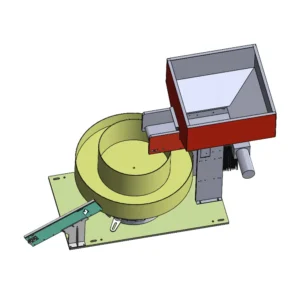

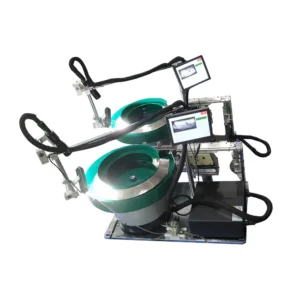

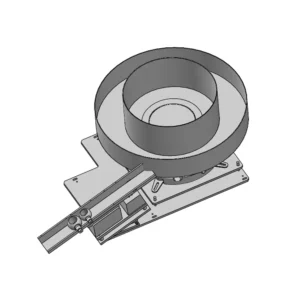

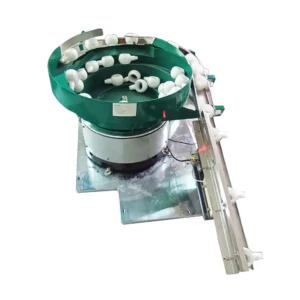

SWOER is a manufacturer specializing in producing and designing flexible feeders, seamlessly integrating robotic arms and CCD camera systems. Our products automate the transfer of materials or components from one position to another on production lines.

Our flexible feeders are adaptable to various sizes, shapes, and weights and ensure swift and precise operations. These systems are crucial in automating production processes, significantly enhancing efficiency and accuracy while reducing the need for manual labor, thus saving time and costs.

At SWOER, our integrated approach to design and production ensures reliable quality. With expedited delivery and competitive pricing, we empower businesses to optimize their operations with dependable and efficient material handling solutions.

Send Inquiry