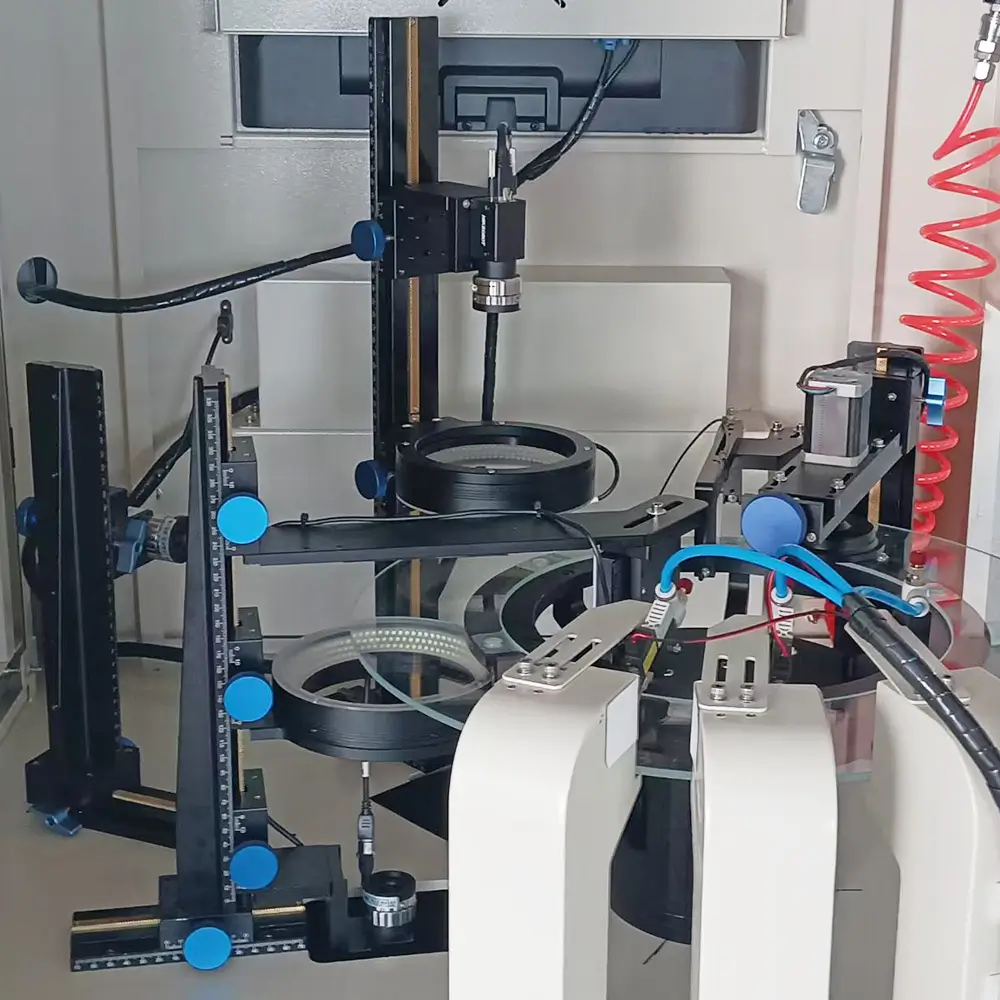

The Vibratory Bowl Feeder with Automated Visual Inspection detects O-ring breaks, deformations, and surface defects with high accuracy. This system feeds parts smoothly while the vision inspection quickly identifies faulty O-rings, preventing defective products from reaching assembly lines. It improves quality control, reduces manual inspection, and ensures reliable production.

Industries like automotive, medical, and electronics manufacturing rely on this solution for high-speed feeding, real-time inspection, and automatic rejection of defective O-rings. By combining bowl feeding and automated visual inspection, manufacturers achieve higher efficiency and consistent quality in their production processes.

To customize a vibratory bowl feeder, please provide the following details:

- O-ring size

- Discharge rate (parts per minute)

- Standard height

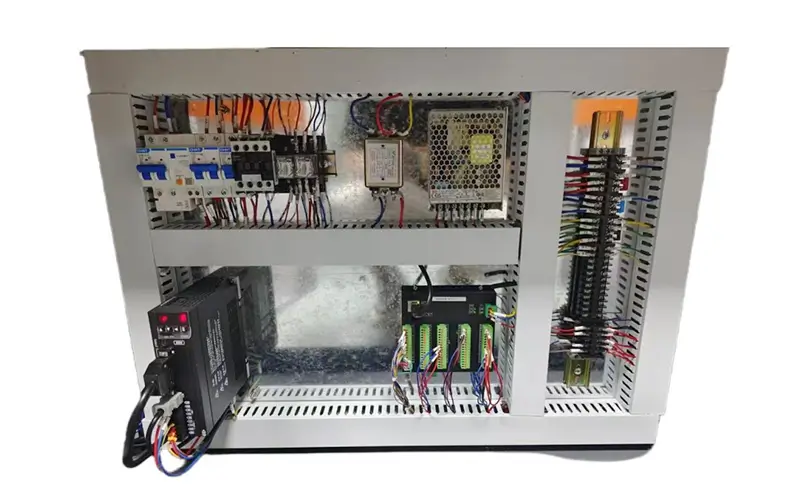

Introduction to Motion Controller

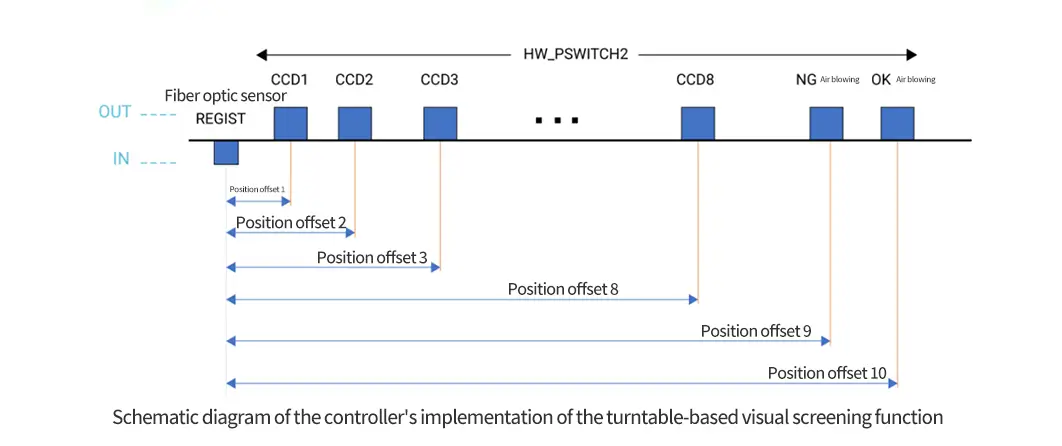

It can perform complex motion control functions like linear interpolation and circular interpolation. It also handles continuous trajectory processing and supports IO high-speed latch input. Additionally, it offers precise output and position synchronization output (PSO). This makes it ideal for turntable visual screening equipment with 2-8 visual inspection stations.

Advantages of controller application in turntable visual screening machine

- It can control the turntable in real-time and record the feedback position of the encoder;

- The high-speed input port connects to the sensor, sensing and recording the parts’ positions.

- The PSO hardware output connects to 2-8 cameras for visual flying, detection, and measurement.

- The PSO hardware output also connects to the airport for screening and classifying visual inspection results.

Reviews

There are no reviews yet.