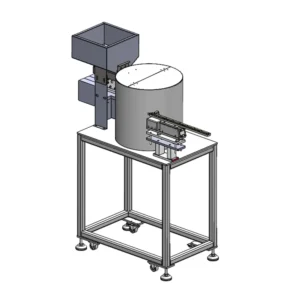

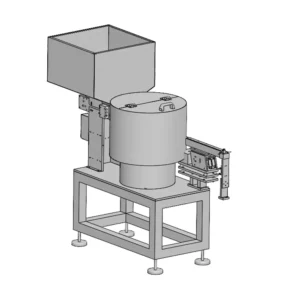

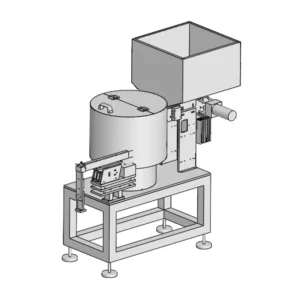

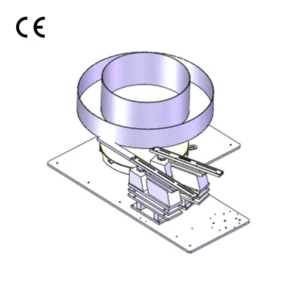

Why Choose SWOER for Custom Vibrating Bowl Feeders?

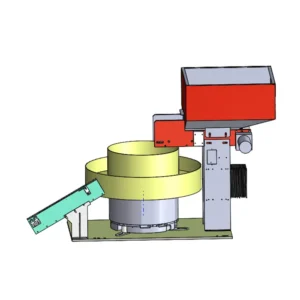

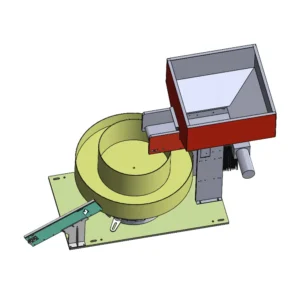

Custom Made: Every bowl feeder is made to fit your part size, shape, and feeding needs.

Accurate and Fast Feeding: SWOER feeders keep parts moving smoothly and quickly in your automation line.

Rich Industry Experience: 10+ years working with car makers, electronics, medical devices, and packaging companies.

Small and Space-Saving: Handles small parts down to 2mm; great for saving space on your machines.

Stable Quality: All feeders are tested carefully to make sure they run well and last long.

Fast Global Service: With a branch in Vietnam and fast support across Asia and Europe, we’re easy to work with.

Information Needed to Customise Your Vibrating Bowl Feeder:

Part Samples or Drawings

Send us real part samples or clear 3D drawings

We check size, shape, material, surface, and how parts need to face

Feeding Direction

Should parts move clockwise or counterclockwise?

Do they need to face up, down, or sideways?

Feeding Speed

How many parts per minute do you need?

Any timing requirements?

Part Size

What’s the smallest and biggest size of your parts (L x W x H)?

Are the parts very small or odd-shaped?

Part Material

Are the parts plastic, metal, rubber, or something else?

This helps us choose the right coating or surface treatment

Working Environment

Is it a cleanroom, hot, humid, or dusty place?

What power supply do you use? (e.g. 220V or 110V)

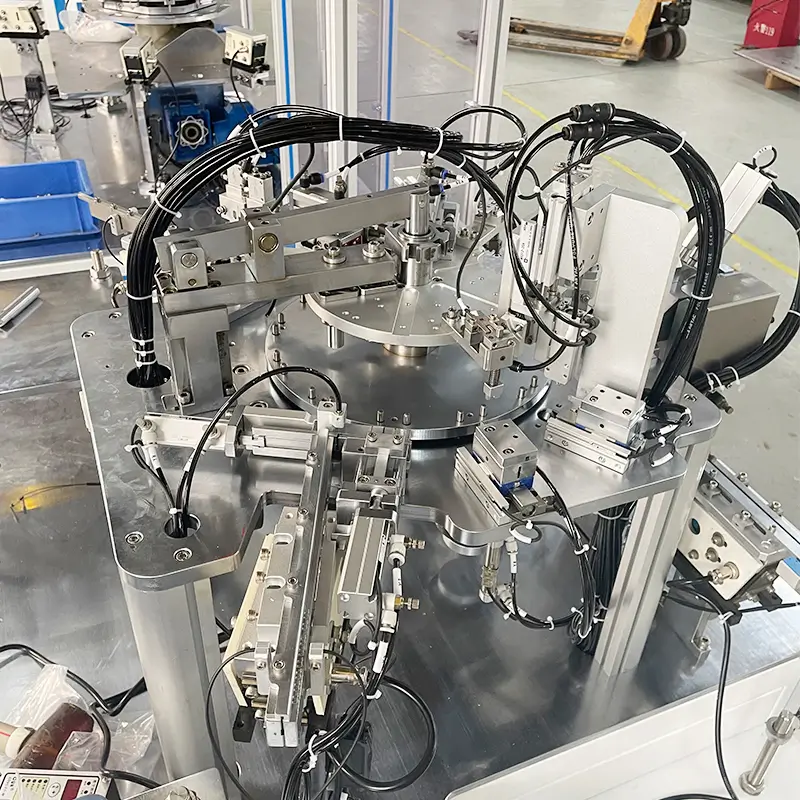

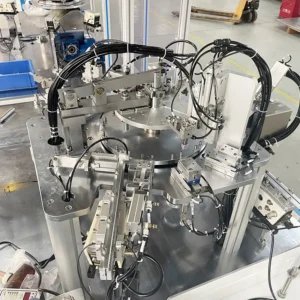

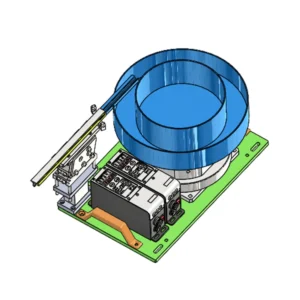

Connected Equipment

Will you use it with a camera system, robot arm, or conveyor?

How do you want the parts to come out — slide, rail, or track?

Bowl Material and Surface Needs

Do you want a stainless steel, aluminium, or plastic bowl?

Need extra coating to reduce noise or protect the parts?

Space for Installation

How much space do you have for the feeder?

Do you need a smaller or special design to fit?

Reviews

There are no reviews yet.