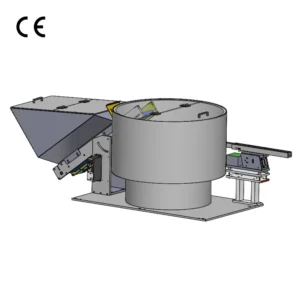

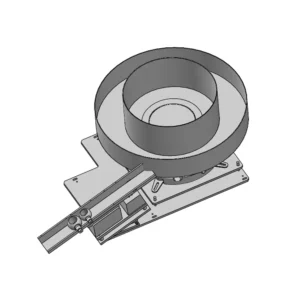

Characteristics of Centrifugal Feeders

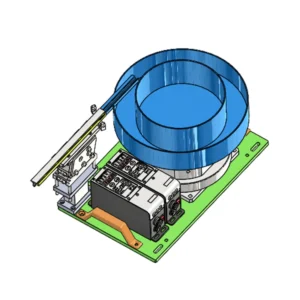

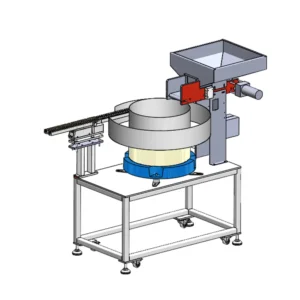

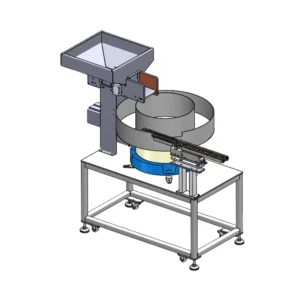

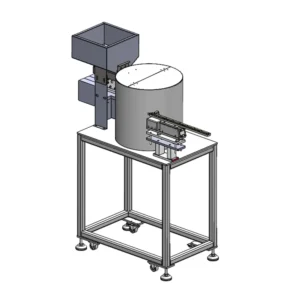

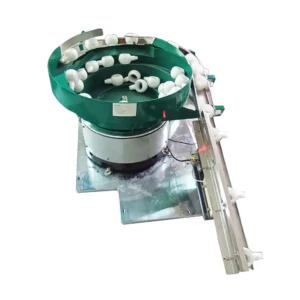

Centrifugal Feeders (or Rotary Feeders) are high-efficiency and gentle feeding systems that operate on a different principle than traditional vibratory bowls.

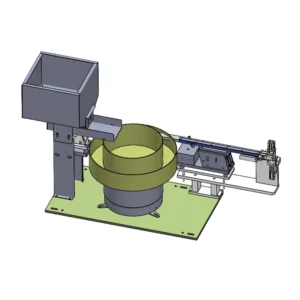

- High Speed and Efficiency

- 説明: The continuous rotary motion allows for non-stop feeding, typically achieving much higher speeds than the reciprocating vibration of traditional bowls.

- アドバンテージ: Ideal for high-volume, high-cycle production requirements.

- Smooth and Quiet Operation

- 説明: The drive motor runs smoothly, and parts slide rather than being tossed, resulting in minimal impact and collision noise.

- アドバンテージ: Creates an excellent working environment, especially suitable for noise-sensitive areas.

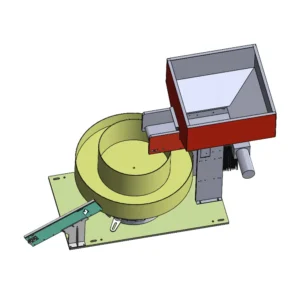

- Extremely Gentle on Parts

- 説明: The feeding process is very gentle, without harsh vibration or impact.

- アドバンテージ: Perfectly protects the surface quality of delicate, easily scratched, plated, or fragile parts.

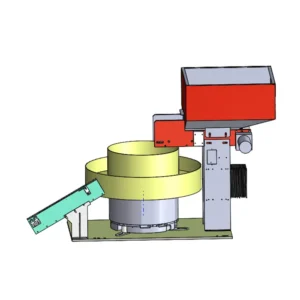

- Effective Handling of Tangle-Prone Parts

- 説明: The combination of a central rotating disc and stationary outer baffles or flappers effectively separates parts that are prone to tangling, such as springs and chains.

- アドバンテージ: Solves the biggest challenge vibratory bowls face with these types of parts.

- Flexible Discharge Direction

- 説明: After parts are oriented to the rim of the disc, they can be discharged from multiple outlets, easily connecting to multiple production lines or workstations.

- アドバンテージ: Increases layout flexibility and overall efficiency.

- Lower Energy Consumption

- 説明: Typically powered by a standard gear motor, which consumes less energy compared to high-power electromagnetic drives used in vibratory bowls.

- アドバンテージ: More energy-efficient and lower operating cost.

Potential Limitations:

- They often lack complex orientation capabilities and primarily separate and feed parts. Orientation tasks may require subsequent track tooling or vision systems.

- The initial cost can be higher than that of a standard vibratory bowl.

レビュー

レビューはまだありません。