What to Do If Oily Rubber Products Stick to the Vibratory Bowl? Solutions?

- Root Cause Analysis

- Oily Surface: The oil film increases adhesion to the metal track.

- Rubber Material: Soft, high friction, and prone to static buildup.

- Insufficient Vibration Force: The bowl’s vibration cannot overcome adhesion and static.

- Systematic Solutions

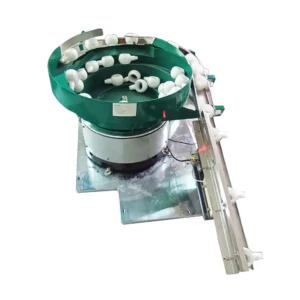

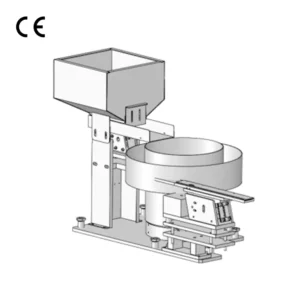

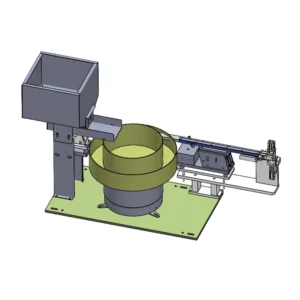

- Preferred Solution: Change the Feeding Method

For oily rubber parts, consider alternatives:

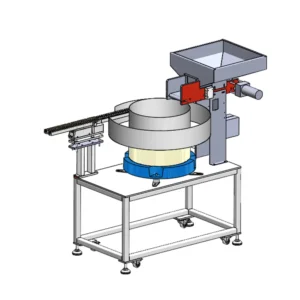

- Pusher Feeder: Reliable, mechanical pushing eliminates vibration dependence.

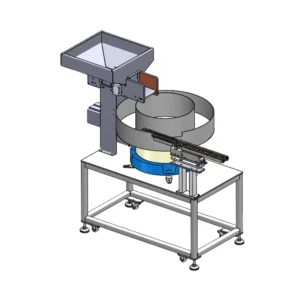

- 遠心フィーダー: Uses gentler, rotational action.

- Flexible Feeder with Vision: Parts are scattered and robot-picked, avoiding sticking.

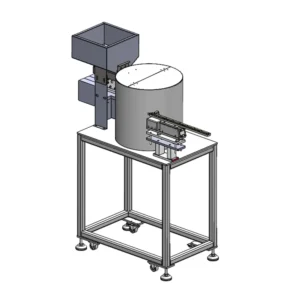

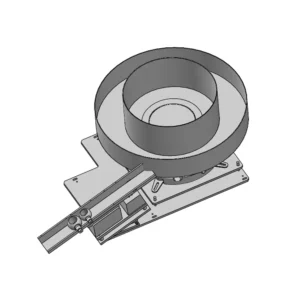

- If a Vibratory Bowl Must Be Used, Implement Extreme Measures:

- Surface Treatment & Modification (Most Critical)

- Teflon/PTFE Coating: Apply a thick, wear-resistant non-stick coating to the track. This is mandatory.

- Use Low-Surface-Energy Materials: Consider UHMWPE for track sections.

- Vibration & Mechanical Adjustment

- Maximize Vibration Energy: Increase amplitude as much as possible without part scattering.

- Optimize Vibration Angle: Fine-tune the leaf spring attack angle for effective part “peeling.”

- Maintain Very Low Part Level: Prevent excess pressure and oil accumulation.

- Active Cleaning & Assisted Separation

- Install Air Blow-Off System: Use precise compressed air jets at key points to blow parts free.

- Add Pre-Cleaning Stage: Clean parts before feeding to remove excess oil.

- Mandatory Static Elimination: Use an ionizing blower directed at the track.

- Environment & Maintenance

- Scheduled Deep Cleaning: Clean the bowl regularly with compatible solvents.

- Control Ambient Temperature: Avoid high temperatures that make oil more fluid.

Final Recommendation: For oily rubber parts, first evaluate non-vibratory alternatives like pusher feeders. If a vibratory bowl must be used, a combination of Teflon coating, strong air blow-off, static elimination, and low part level is essential, along with readiness for high-frequency maintenance.

レビュー

レビューはまだありません。