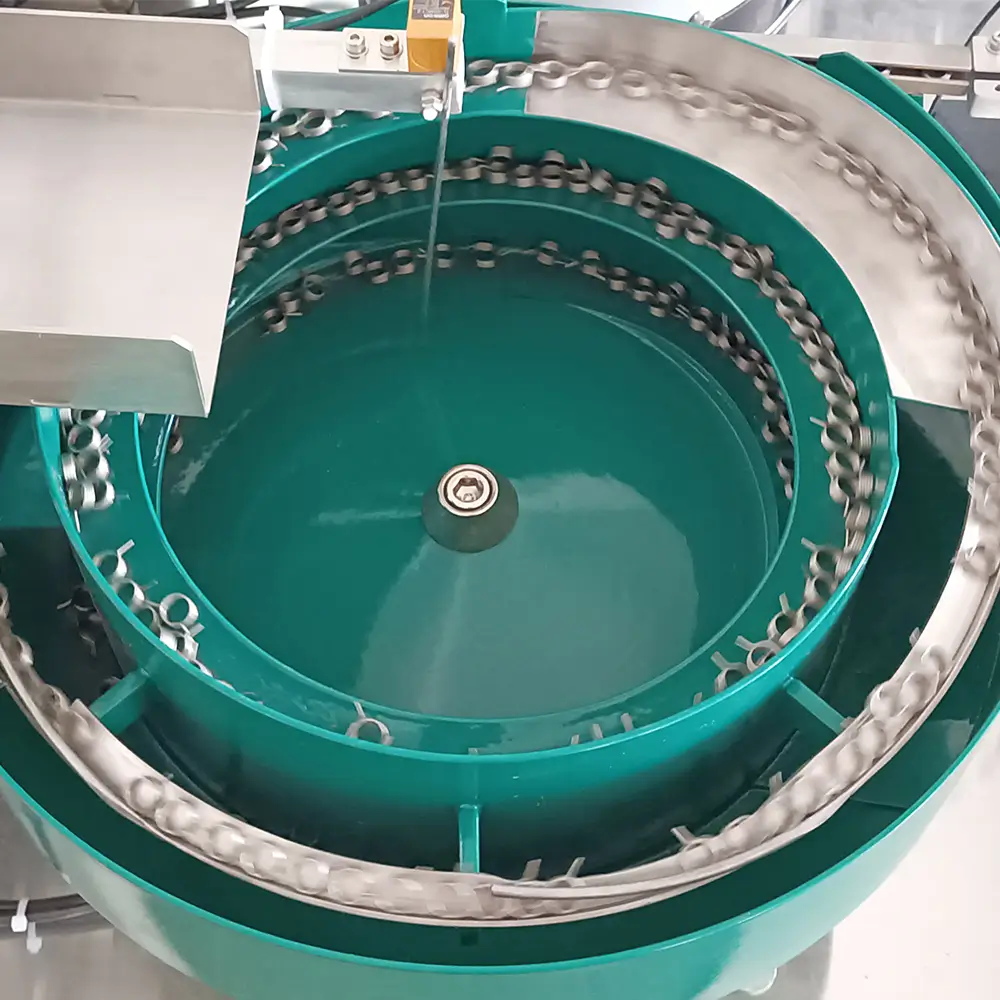

1、 Comparison of Working Principles and Characteristics Characteristic vibration feeder pusher/feeder The working principle utilizes the electromagnetic drive and resonance principle to generate small vertical torsional vibrations in the disk body, and through inertia and friction, the parts move forward along the spiral track and complete orientation. It is usually a linear motion mechanism (cylinder, electric push rod) that pushes the disorderly stacked parts forward one by one through reciprocating push claws or push plates. Core functions include sorting, orientation, transportation separation, counting, and transportation Advantage 1. Complex orientation: It can arrange messy parts in a unified and specific direction through clever mechanisms on the track. Continuity: The feeding process […]

カテゴリーアーカイブ: Flex Feeder

Vibration feeder are widely used in automated production, but they present some common pain points. Below are the main issues and their solutions: Material jamming or blockage Reason: Irregular material shape or unreasonable design of the vibratory bowl. Solution: Optimize material design: Ensure the material shape is suitable for the vibratory bowl. Adjust vibration parameters: Regulate frequency and amplitude to ensure smooth material flow. Improve track design: Optimize track width and angle to reduce stalling. Excessive noise Reason: Mechanical vibration and noise are generated during the operation of the vibratory bowl. Solution: Vibration damping measures: Use vibration damping pads or feet. Soundproofing material: Install soundproofing material around the vibrating tray. […]

The vibrating feeder is an indispensable basic equipment in modern automated production, and its core value lies in automatically orienting and sorting chaotic small parts (such as screws, nuts, rivets, electronic components, capsules, etc.), and stably conveying them to the next workstation. It can bring significant advantages and benefits to customers in the following aspects: Core direct benefits: improving efficiency and reducing costs Extremely high production efficiency High speed continuous operation: The vibrating feeder system can work continuously for 7×24 hours, and the feeding speed can reach tens to thousands of pieces per minute (depending on the size and complexity of the parts), far exceeding manual operation speed. Shortening production […]

In the era of Industry 4.0, intelligent manufacturing has put forward higher requirements for the flexibility of production equipment. Traditional feeders often can only handle a single type of material, making it difficult to meet the production needs of modern manufacturing with multiple varieties and small batches. The emergence of flexible feeders has completely changed this situation. The flexible feeder adopts a modular design, which can quickly adapt to materials of different shapes and sizes by replacing different feeding modules. This design breaks through the limitations of traditional feeders, allowing one device to handle a variety of materials ranging from small electronic components to large mechanical parts. For example, after […]

A flexible feeder system, also known as a flex feeder, flexible part feeder, or robotic pick and place system, efficiently handles special-shaped parts ranging from 0.1mm to 150mm. Why Choose a Flexible Feeder System? Industries like automotive, insert injection molding, and watch ceramics demand high precision. Traditional vibratory feeders struggle with irregular parts, making automation difficult. SWOER’s flexible visual material selection system solves these challenges, ensuring efficient, damage-free feeding. Key Advantages: Protects Delicate Electroplated Parts Traditional vibratory feeders cause parts to scratch as they circulate in the bin. Our flexible feeder eliminates reciprocating feeding, ensuring scratch-free handling. Handles Special-Shaped Workpieces Standard feeders rely on geometric shapes and mass distribution for […]

部品供給オプションについてご相談し、お見積りをご希望の場合は、弊社までお問い合わせください。