Getting to Know Vibratory Bowl Feeders

Vibratory bowl feeders are crucial elements in today’s manufacturing, offering effective and dependable solutions for handling parts across various industries. These adaptable tools use vibration to align and deliver parts along a specified path, guaranteeing a seamless and steady flow throughout production.

Understanding the Basics

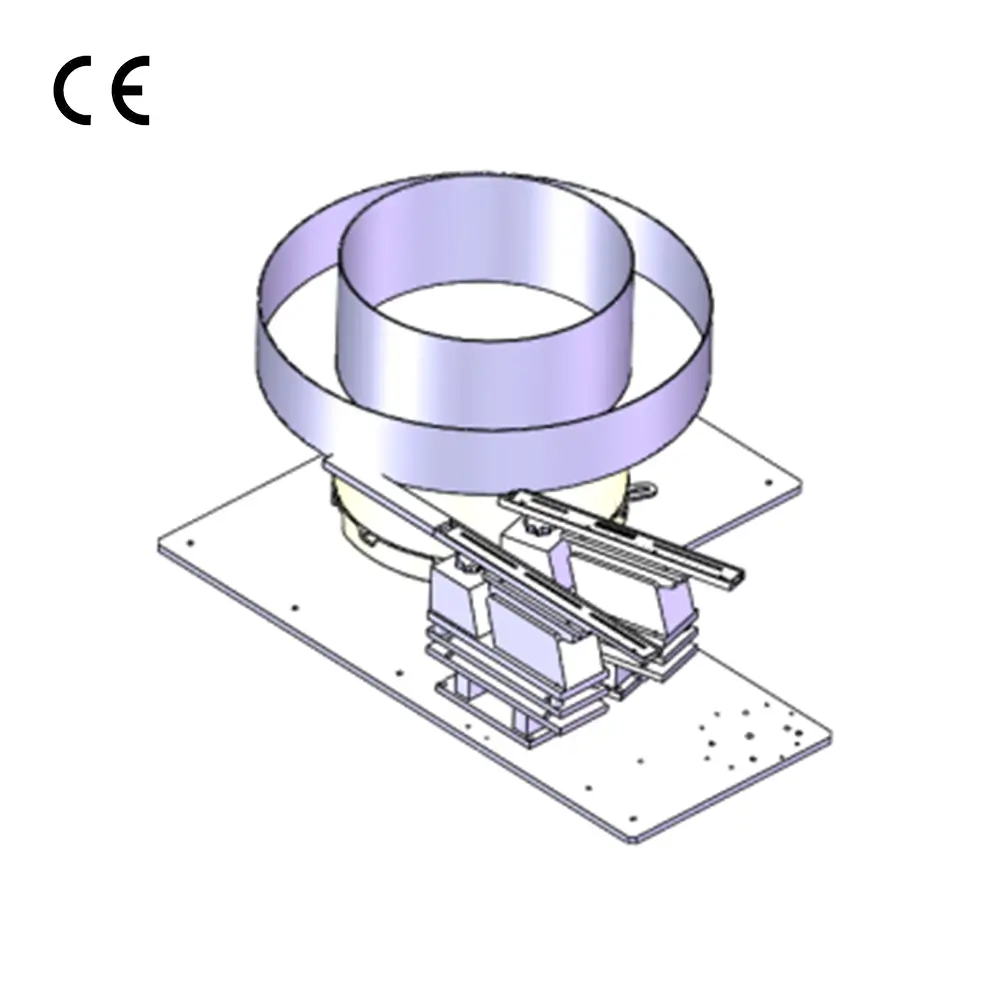

At the heart of a vibratory bowl feeder is a bowl-shaped container, typically made of stainless steel or other durable materials. Within this bowl, a vibrating mechanism generates rapid movements, causing parts placed inside to move in a controlled manner. By adjusting various parameters such as vibration frequency and amplitude, operators can customize the feeding process to suit specific part sizes and shapes.

How Vibratory Bowl Feeders Work

When powered on, the vibratory bowl feeder generates vibrations that cause the parts to move along the track or spiral pathway inside the bowl. As the parts reach the desired orientation, they are discharged from the feeder and directed towards downstream processes such as assembly, packaging, or inspection.

Importance in Manufacturing Processes

Vibratory bowl feeders play a crucial role in streamlining factory operations by automating the handling of small and medium-sized parts. By eliminating manual sorting and feeding tasks, these devices help reduce labor costs, minimize errors, and improve overall production efficiency.

Benefits of Integrating Vibratory Bowl Feeders in Factory Operations

Increased Production Efficiency

By automating the parts feeding process, vibratory bowl feeders significantly enhance production efficiency, allowing factories to meet growing demand while maintaining high standards of quality and accuracy.

Consistent and Reliable Parts Handling

Vibratory bowl feeders ensure uniform part orientation and positioning, reducing the risk of jams, misfeeds, and assembly errors commonly associated with manual handling methods.

Reduced Labor Costs

With vibratory bowl feeders handling repetitive and labor-intensive tasks, workers can be redeployed to more skilled and value-added roles within the production line, maximizing workforce productivity.

Enhanced Safety Measures

By minimizing direct human interaction with moving parts and machinery, vibratory bowl feeders help create a safer working environment, reducing the risk of accidents and injuries on the factory floor.

Optimizing Vibratory Bowl Feeder Setup

Selecting the Right Vibratory Bowl Feeder for Your Factory Needs

Choosing the appropriate size, design, and configuration of a vibratory bowl feeder is essential for achieving optimal performance and compatibility with existing production equipment.

Proper Installation and Maintenance Procedures

To ensure reliable operation and longevity, it’s crucial to follow manufacturer guidelines for installing, calibrating, and maintaining vibratory bowl feeders on a regular basis.

Adjusting Feed Rates and Amplitude for Maximum Efficiency

Fine-tuning the vibration frequency and intensity allows operators to optimize feed rates and minimize part wear, maximizing the lifespan of both the feeder and the handled components.

Improving Production Line Performance with Vibratory Bowl Feeders

Seamless Integration into Existing Systems

Vibratory bowl feeders can be seamlessly integrated into existing production lines, complementing other automation technologies such as conveyor belts, robots, and assembly machines.

Minimizing Downtime and Production Halts

With their robust construction and reliable operation, vibratory bowl feeders help minimize unplanned downtime and production interruptions, ensuring continuous workflow and output consistency.

Enhancing Quality Control Measures

Vibratory bowl feeders improve product quality and consistency by delivering parts with precision and repeatability, thereby reducing the chances of defects and the need for rework downstream.

Know more about vibratory bowl feeder manufacturers and bowl feeding systems with CCD supplier in China, and find the one-solution for keywords online with fast delivery, competitive price, and reliable quality.

Contact Us