Article structure:

- Introduction:

- The key role of the flexible feeding system

- Accurate perception of the CCD vision system

- Flexible operation of industrial spider robot arm

- Advantages after integration of the three

- Technical difficulties and solutions for the integration scheme

- Future development trends

- Summary

In modern automated manufacturing, the seamless integration of flexible feeding systems, CCD vision systems, and industrial spider robot arms has become the cornerstone of highly efficient and precise production lines. This article delves into this integration’s advantages, technical challenges, and future trends.

The Crucial Role of Flexible Feeding Systems

As the “lifeblood” of automated production lines, flexible feeding systems deliver components to processing stations at a stable speed and with precise positioning. Their high flexibility, reliability, and ease of integration make them indispensable in automated manufacturing.

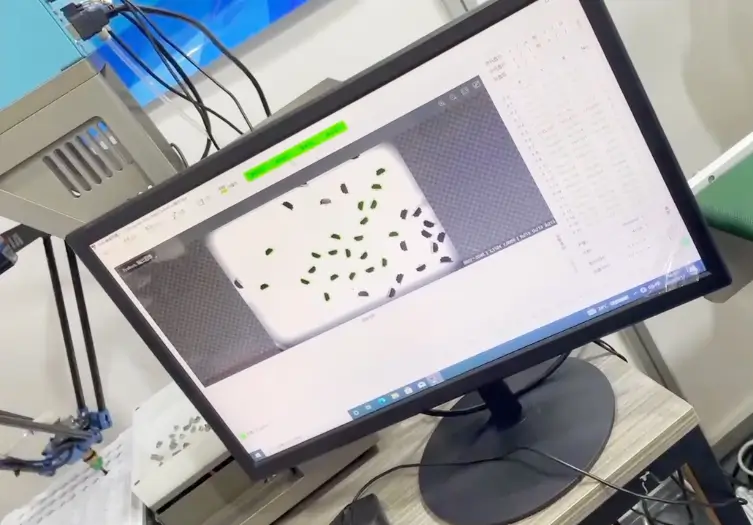

The Precise Perception of CCD Vision Systems

As the “eyes” of the system, CCD vision systems capture images and process them to identify, locate, and measure workpieces accurately. Their high resolution, frame rate, and rich image processing algorithms provide reliable visual information for subsequent robotic operations. The Agile Manipulation of Industrial Spider Robot Arms

With their high degrees of freedom, large workspace, and high precision, industrial spider robot arms play an increasingly important role in flexible production lines. Their anthropomorphic arm design enables them to adapt to various complex tasks.

Advantages of Integrated Systems

The integration of flexible feeding systems, CCD vision systems, and industrial spider robot arms offers several advantages:

- Increased production efficiency: Automated feeding, identification, and grasping significantly enhance production efficiency.

- Improved product quality: The high-precision identification of CCD vision systems and the precise operation of robot arms ensure consistent product quality.

- Enhanced production flexibility: Systems can quickly adapt to changes in product models and production processes, improving production line flexibility.

- Reduced labor costs: By minimizing manual intervention and reducing labor intensity, production efficiency is increased.

Technical Challenges and Solutions for Integration

The integration of these systems presents several technical challenges:

- Vision algorithm optimization: Vision algorithms need to be optimized for different workpieces and production environments to improve recognition accuracy and robustness.

- Motion control coordination: The motion of the robot arm, feeding system, and vision system must be coordinated to ensure synchronization and precision.

- System integration: Integration of equipment from different manufacturers requires ensuring system stability and reliability.

Industrial Spider Robot Operation Video

Future Trends

With the continuous development of artificial intelligence and machine learning, the integration of flexible feeding, CCD vision systems, and industrial spider robot arms will usher in new opportunities. In the future, we can expect:

- Intelligence: The introduction of artificial intelligence will enable robots to learn and adapt autonomously.

- Flexibility: Systems will become more flexible to adapt to more complex and variable production environments.

- Networking: Production line equipment will be interconnected to enable real-time monitoring and remote control.

Conclusion

The integration of flexible feeding systems, CCD vision systems, and industrial spider robot arms is key to achieving automated production. Through close cooperation, these systems can significantly enhance production efficiency and product quality, effectively meeting the demands of modern manufacturing for flexibility, intelligence, and efficiency. As technology continues to evolve, we can anticipate witnessing even more intelligent and flexible automated production lines in the future.