- Introduction to Feeder Systems

- Exploring Vibratory Feeder Bowl Systems

- How Centrifugal Feeders Work in Material Handling

- Flexible Feeding Systems: A Modern Solution

- Step Feeding Solutions: Precision and Simplicity

- Advantages of Optimised Material Feeding Systems

- Conclusion: Choosing the Right Feeder System

Introduction to Feeder Systems

Feeder systems play a critical role in automation and manufacturing by ensuring a smooth flow of parts and materials. Whether you’re managing production for automotive parts, electronics, or packaging, having the right system can save time and boost efficiency. In this blog, we’ll discuss vibratory feeder bowl systems, centrifugal feeders, flexible feeding systems, and step feeding solutions to help you understand their unique benefits.

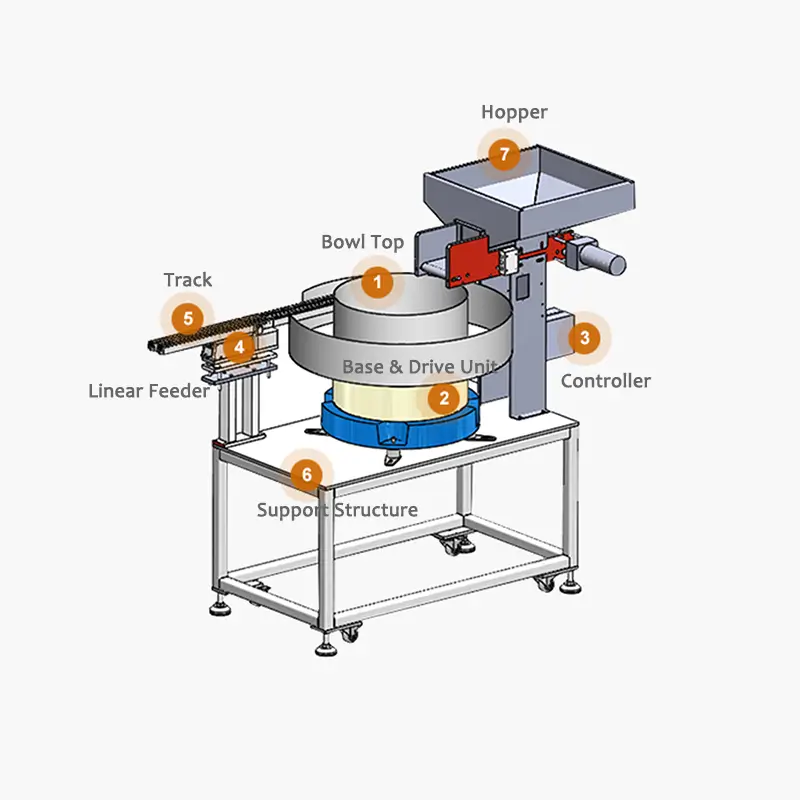

Understanding Vibratory Feeder Bowl Systems

Vibratory feeder bowl systems are key to many production lines. They use vibrations to sort and deliver parts with precision. Common in industries like automotive and electronics, they handle small parts quickly and reliably.

How Centrifugal Feeders Work in Material Handling

Centrifugal feeders are designed for high-speed operations and are perfect for lightweight, uniform parts. They use centrifugal force to sort and feed parts efficiently, making them popular for packaging and pharmaceutical industries. Their low maintenance needs and high reliability make them stand out in material feeding systems.

Flexible Feeding Systems: A Modern Solution

For industries requiring adaptability, flexible feeding systems are a game changer. These systems, often paired with robotic arms and vision systems, can handle multiple part types without manual intervention. They are perfect for businesses looking to future-proof their production lines.

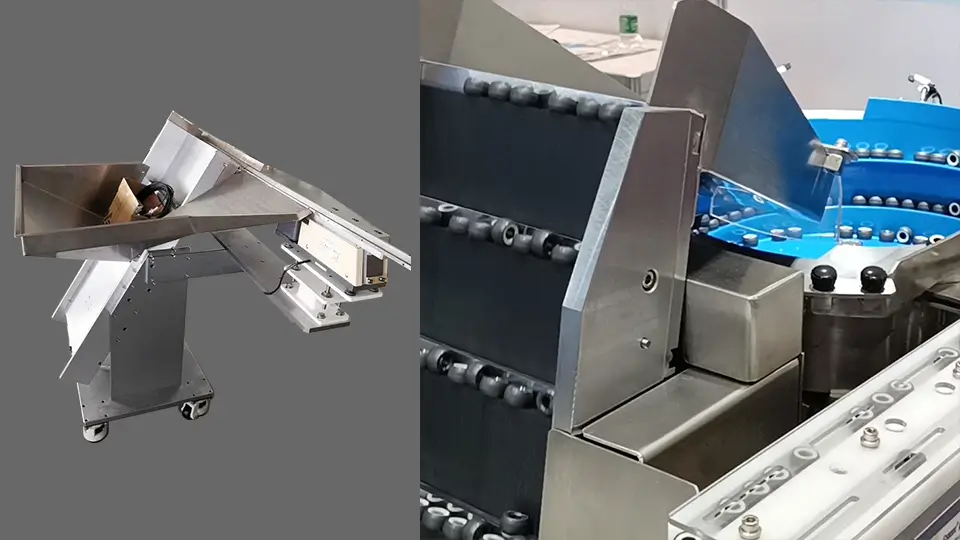

Step Feeding Solutions: Precision and Simplicity

Step feeding solutions are ideal for fragile or heavy parts that need careful handling. By feeding parts step-by-step, they ensure minimal damage while maintaining a steady flow. These systems are commonly used in applications like assembly and sorting.

Advantages of Optimised Material Feeding Systems

A well-designed material feeding system can:

- Increase production efficiency.

- Reduce manual intervention.

- Minimise downtime and maintenance costs.

SWOER offers customised solutions to meet your unique requirements, ensuring smooth and reliable operations.

Conclusion

Choosing the Right Feeder System

Selecting the right feeder system depends on your specific needs, such as the type of parts, required speed, and industry demands. SWOER is here to help you choose the best solution, whether it’s a vibratory feeder bowl system, centrifugal feeder, flexible feeding system, or step feeding solution.

In addition, we also have a device that can automatically identify material defects: Rotary Visual Screening Machine

Ready to optimise your production line? Contact SWOER today!