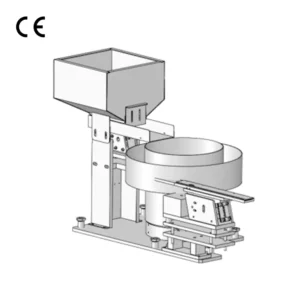

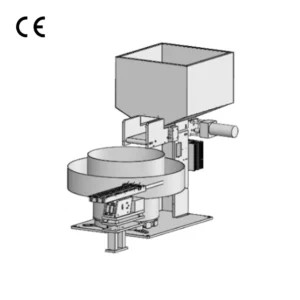

How Does a Vibratory Bowl Work with an Assembly Machine?

The vibratory bowl acts as an “automated parts feeder” within an assembly system. Its core task is to take bulk, disordered components and deliver them oriented and ready for the assembly machine to use.

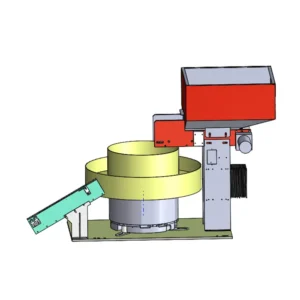

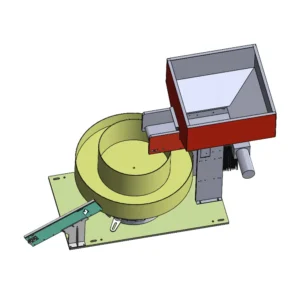

- Sorting and Orienting

- Process: Bulk parts are loaded into the bowl. Vibration moves them up a spiral track where tooling filters and orients them, ensuring only correctly aligned parts pass through.

- Transferring and Presenting

- Process: Oriented parts exit into a linear feeder, which transports them smoothly to a precise, fixed presentation point.

- Sensing and Signaling

- Process: A sensor at the end of the linear feeder detects a part’s presence and sends a signal to the machine’s sistema de control.

- Executing Assembly

- Process: The controller triggers an actuator (e.g., a pneumatic gripper, screwdriver, or press) to pick the part and place it into the product.

- Cycling and Integration

- Process: Once the part is taken, the sensor signals “empty,” prompting the system to feed the next part, creating a continuous cycle.

In summary, the vibratory bowl and assembly machine, linked via sensors and a control system, create an automated loop from bulk parts to precise assembly—a classic combination in automated manufacturing.

Valoraciones

No hay valoraciones aún.