In industrial production, vibratory bowl feeders play a crucial role in organizing and automatically feeding parts. Keeping them in top condition isn’t just about preventing breakdowns—it’s about maximizing efficiency and ensuring smooth operations. Regular maintenance can extend the feeder’s lifespan, boost performance, and reduce costly downtime. Let’s dive into some essential care tips.

Keep Vibratory Bowl Feeder Clean

A clean vibratory feeder runs better—it’s that simple. Dust, oil, and debris don’t just make the equipment look bad; they can also disrupt part flow, leading to jams and blockages. To prevent this:

- Daily:Wipe down the feeder plate with a soft, clean cloth.

- Regularly:Clear out the internal track to remove built-up dirt.

- Hard-to-reach areas?Use compressed air to blast away fine particles.

- Food or pharma applications?Use detergents that meet hygiene standards to prevent contamination.

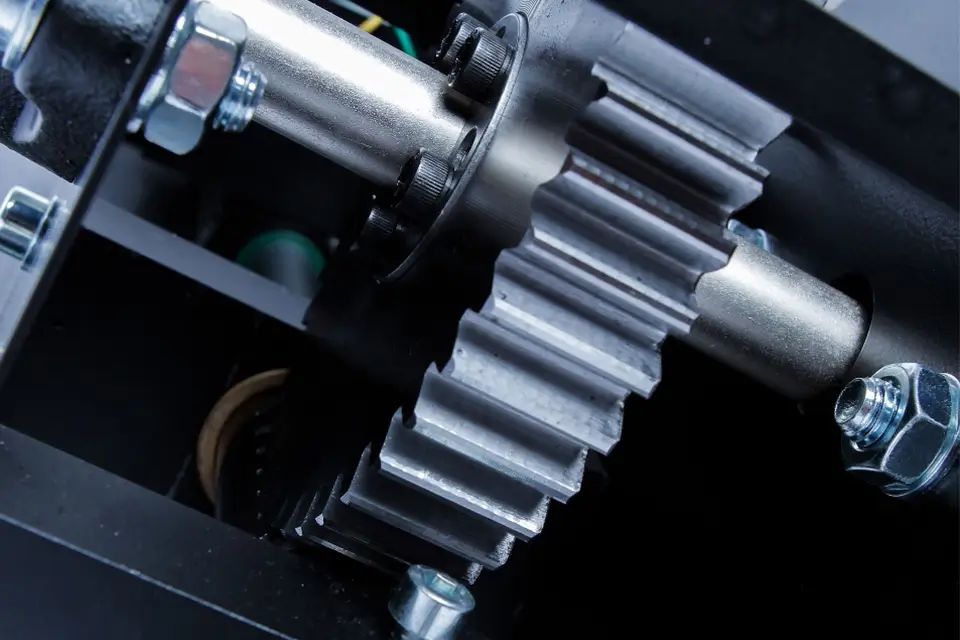

Inspect Bowl Feeder Mechanical Components

Small mechanical issues can quickly turn into big problems. Regularly check these key areas of your vibratory parts feeder:

- Springs– Are they loose or deformed? Weak springs can reduce vibration efficiency. Adjust or replace them if needed.

- Bolts– Ensure all connections are tight to avoid unexpected failures.

- Track lining– Look for wear and replace it before it starts affecting part movement.

- Motor bearings– Proper lubrication is crucial. Add oil at manufacturer-recommended intervals to prevent dry friction damage.

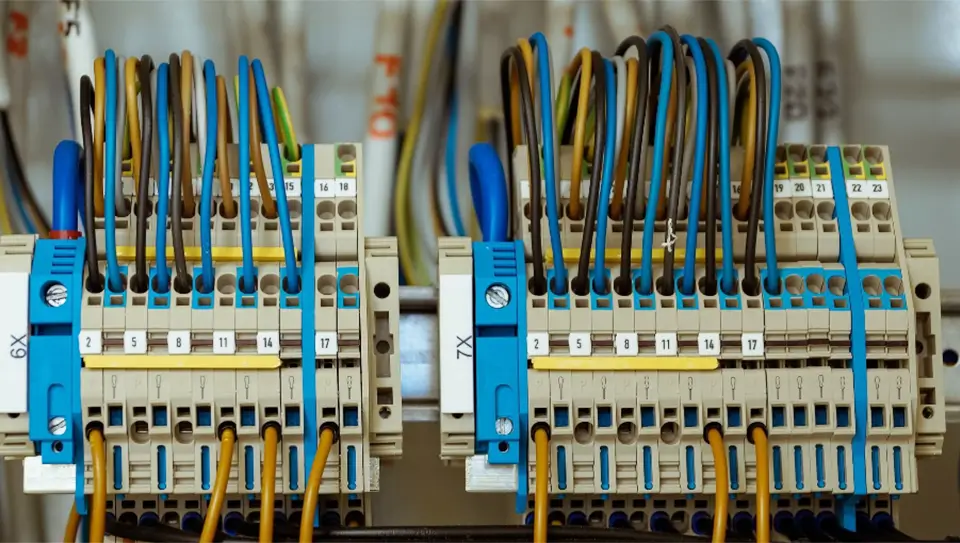

Electrical Vibratory Feeder System Maintenance

A bowl feeder automation system relies on a stable electrical setup. Faulty wiring or worn-out components can lead to performance issues—or worse, safety hazards.

- Check power cablesfor damage or aging.

- Ensure the grounding wire is secureto prevent electrical leaks.

- Test control circuits– The start/stop button should respond instantly, and speed controls should adjust smoothly.

- Using a frequency converter?Follow the manufacturer’s instructions for updates and settings to keep everything running efficiently.

- Before any electrical work– Always cut the power and take proper safety precautions.

Plan for Vibratory Bowl Feeder Preventive Maintenance

Don’t wait for a breakdown to start thinking about maintenance. A solid preventive maintenance plan keeps your bowl feeder automation system running reliably.

- High-usage feeders (24/7 operation)?Inspect them daily or weekly.

- Intermittent-use feeders?Monthly checks may be enough.

- Keep recordsof inspections and servicing. This helps predict future maintenance needs and reduces the risk of unexpected failures.

Final Thoughts About Vibratory Bowl Feeder

Taking care of your vibratory bowl feeder isn’t just about avoiding repairs—it’s about keeping production lines moving smoothly. With proper cleaning, mechanical checks, electrical maintenance, and a solid maintenance schedule, your equipment will stay in peak condition. The result? Fewer delays, lower costs, and higher efficiency.