- Custom Vibratory Feeders for Housing Components

2. What Are Housing Components?

- 2.1 Common Examples of Housing Parts

- 2.2 Importance of Feeding Solutions for Housing Production

3. Vibratory Feeders: The Ideal Solution for Housing Components

- 3.1 How Do Vibratory Feeders Work?

- 3.2 Benefits of Vibratory Feeders for Housing Parts

- 3.2.1 Precision and Consistency

- 3.2.2 Enhanced Production Efficiency

- 3.2.3 Versatility for Diverse Applications

4. SWOER’s Expertise in Housing Parts Feeding Solutions

- 4.1 Why Choose SWOER for Custom Vibratory Feeders?

- 4.1.1 Customized Designs to Meet Your Needs

- 4.1.2 Competitive Pricing Without Compromising Quality

- 4.1.3 Fast Lead Times to Keep You on Schedule

5. Applications of Vibratory Feeders in Housing Components

- 5.1 Automotive Industry

- 5.2 Plastic and Metal Processing

- 5.3 Construction and Infrastructure

6. Key Considerations for Choosing a Vibratory Feeder for Housing Parts

- 6.1 Material Compatibility

- 6.2 Feeder Size and Design

- 6.3 Maintenance and Durability

7. FAQs About Housing Parts Feeding Solutions

- 7.1 How Can Vibratory Feeders Improve Housing Production?

- 7.2 Are Vibratory Feeders Suitable for Small Housing Components?

8. Conclusion: Boost Your Production with SWOER’s Custom Vibratory Feeders

Introduction

Let’s talk housing components. These critical parts form the backbone of countless products, from automotive assemblies to construction equipment. Feeding these components efficiently is where vibratory feeders shine. At SWOER, we specialise in crafting custom vibratory feeders tailored to the unique needs of industries handling housing components. But what makes these feeders the ultimate solution for your production line? Let’s dive in!

What Are Housing Components?

Housing components are enclosures or structural parts that protect and support internal mechanisms. Think of car engine covers, metal casings, or even plastic shells for electronics. These parts must be fed into production lines with precision to maintain quality and efficiency.

Common Examples of Housing Parts

- Automotive casings (engine covers, dashboard housings)

- Plastic shells for appliances and electronics

- Structural enclosures for machinery

- Construction fittings like pipe housings

Importance of Feeding Solutions for Housing Production

Without an efficient feeding system, production slows, and costs increase. Housing components often come in various shapes, sizes, and materials, making manual handling impractical. That’s where vibratory feeders save the day!

Vibratory Feeders: The Ideal Solution for Housing Components

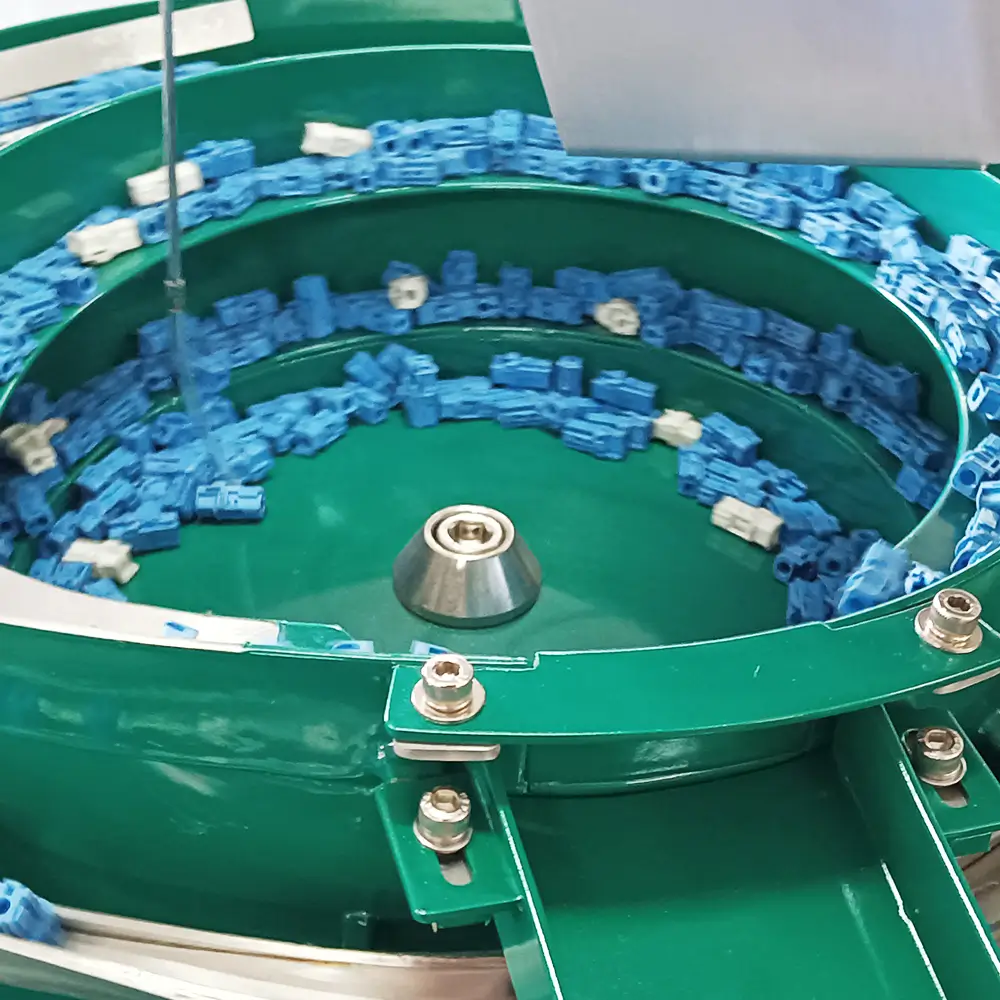

How Do Vibratory Bowl Feeders Work?

Think of vibratory feeders as a sophisticated conveyor belt with a rhythmic twist. Using controlled vibrations, these feeders move housing parts along a predefined path, ensuring they’re correctly oriented and ready for the next step.

Benefits of Vibratory Feeders for Housing Parts

Precision and Consistency

No more misaligned parts or wasted time. Vibratory feeders ensure every housing component reaches its destination in perfect orientation.

Enhanced Production Efficiency

By automating feeding processes, vibratory feeders reduce manual labour, speeding up production while maintaining accuracy.

Versatility for Diverse Applications

Whether it’s lightweight plastic casings or heavy-duty metal housings, vibratory feeders handle it all.

To learn more about SWOER vibratory bowl feeders, please click:

SWOER’s Expertise in Housing Parts Feeding Solutions

Why Choose SWOER for Custom Vibratory Feeders?

Customized Designs to Meet Your Needs

Our feeders are customised to match the specific requirements of your housing components, ensuring seamless integration with your production line.

Competitive Pricing Without Compromising Quality

High quality doesn’t have to break the bank. SWOER offers top-notch feeders at prices that fit your budget.

Fast Lead Times to Keep You on Schedule

We understand the importance of time in manufacturing. That’s why we prioritise fast turnaround times without sacrificing quality.

Efficient Housing Feeding: Vibratory Feeder Operation Video

Applications of Vibratory Feeders in Housing Components

Automotive Industry

From engine casings to dashboard assemblies, vibratory feeders keep automotive production lines running smoothly.

Plastic and Metal Processing

Perfect for handling a variety of materials, including lightweight plastics and durable metals.

Construction and Infrastructure

Ideal for feeding structural components used in construction, such as pipe fittings and metal housings.

Key Considerations for Choosing a Vibratory Feeder for Housing Parts

Material Compatibility

Ensure your feeder can handle the specific materials of your housing components, from plastics to metals.

Feeder Size and Design

The size and design of the feeder should align with your production needs and the dimensions of your components.

Maintenance and Durability

Choose a feeder designed for long-term performance with minimal maintenance requirements.

FAQs About Housing Parts Feeding Solutions

How Can Vibratory Feeders Improve Housing Production?

Vibratory feeders reduce errors and improve overall efficiency by automating and streamlining the feeding process.

Are Vibratory Feeders Suitable for Small Housing Components?

Absolutely! Vibratory feeders excel at handling small, intricate parts with precision and care.

Conclusion: Boost Your Production with SWOER’s Custom Vibratory Feeders

At SWOER, we pride ourselves on delivering vibratory feeders that enhance productivity and ensure quality in housing component production. Ready to transform your production line? Contact us today and experience the SWOER difference!