In today’s fast-paced world of packaging, speed and precision aren’t just nice to have—they’re essential. If you’re bottling anything from fizzy drinks to pharmaceuticals, you know that a single hiccup in the cap feeding process can slow everything down. That’s where the automatic cap sorting and feeding system comes into play. It’s the unsung hero that keeps your production line running smoothly.

What Exactly Is an Automatic Cap Sorting and Feeding System?

Think of it as the gatekeeper for every bottle on your line. Its job is to take a pile of random caps, sort them, orient them correctly, and send them off to the capping machine. All of this happens quickly, efficiently, and without human intervention.

The star of the show? The vibratory cap feeder. It uses controlled vibrations to guide caps along a track until they’re upright and ready for capping. No more manual sorting. No more jams. Just smooth, continuous motion.

The Key Components That Make It All Work

Let’s break it down:

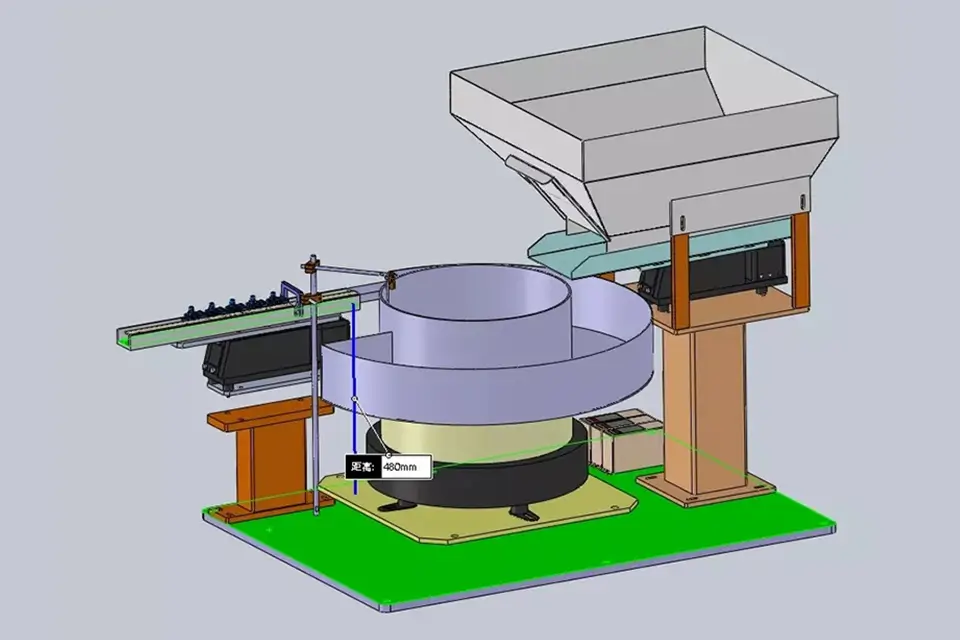

- Vibratory Cap Feeder

This is where the magic starts. It’s a vibrating bowl that gently moves the caps along a specially designed track. As the caps travel, they’re oriented into the correct position.

- Cap Sorting Mechanism

Not every cap gets it right the first time. That’s where the sorting mechanism comes in. It flips or rejects any caps that aren’t properly aligned.

- Cap Hopper with Elevator

Imagine loading thousands of caps at once and letting the system handle the rest. The hopper stores them, and an elevator delivers them gradually to the vibratory bowl—keeping the system fed without constant operator input.

- Cap Delivery System

Once sorted, the caps are delivered via chute, conveyor, or air blast straight to your capping machine.

Why Use a Vibratory Cap Feeder?

Because it just makes sense. Here’s what you get:

- High-Speed Efficiency

Need to handle 200 caps a minute? No problem. These systems are built for speed.

- Customised for Your Caps

Flip-tops, screw caps, press-on, odd shapes—you name it, it can be customised for it.

- Less Downtime

Fewer jams mean fewer delays. Your line keeps moving, and your team stays productive.

- Low Maintenance

With minimal moving parts, these systems are built to last. That means less time fixing and more time producing.

- Cost-Effective

Sure, there’s an upfront cost. But when you factor in reduced labour and increased efficiency, you’ll see the return on investment fast.

Who Uses These Cap Feeder Systems?

Pretty much every industry that bottles something:

- Léčiva

Precision and hygiene are key. Automatic feeders deliver both.

- Food & Beverage

From ketchup to cola, cap feeders keep lines moving without a hitch.

- Cosmetics & Personal Care

Small, delicate caps? No problem. These systems handle them with care.

- Chemical & Household Products

Durable stainless-steel options can handle tough substances safely and reliably.

Choosing the Right System: What to Look For

Not all cap feeders are created equal. Here’s what to consider:

- Cap Size & Shape

Make sure the feeder can handle the variety of caps in your product line.

- Throughput Requirements

Match the system to your production speed—or even better, exceed it.

- Hygienic Standards

For food and pharma, stainless steel and easy-clean designs are a must.

- Floor Space

Don’t overcrowd your factory floor. Choose a compact design that fits your layout.

Why Go Custom?

Here’s the truth: off-the-shelf machines don’t always fit your specific needs. That’s why going custom makes a difference. At SWOER, we build vibratory cap feeders tailored to your product, your layout, and your goals.

Our engineers take the time to understand what you need and deliver a solution that fits seamlessly into your line. Whether you’re dealing with tiny flip-top caps or large screw-on lids, we’ve got you covered.

Going a Step Further: Full Automation

Want to take it up a notch? Modern cap sorting systems can integrate with:

- Vision Inspection Systems – to detect defects in real time

- Robotic Pick-and-Place Arms – to grab and orient unusual cap shapes

- Auto Reject Units – to remove caps that don’t meet your quality standards

The result? Less human error, higher consistency, and better product quality—without slowing down your production.

Závěrečné myšlenky

An automatic cap sorting and feeding system isn’t just a piece of machinery. It’s the engine that keeps your packaging line firing on all cylinders. With the right setup, you’ll reduce downtime, boost productivity, and deliver a consistent, high-quality product—day in, day out.

If you’re ready to upgrade your line or you’re starting from scratch, talk to us at SWOER. We’ll help you find the perfect fit, customised for your caps, your pace, and your industry.