- Introduction: What is a Component Feeder and Why is it Crucial for Modern Industries?

- The Role of Component Feeders in Automation

- What is a Vibratory Parts Feeder?

- How Vibratory Feeders Work

- The Mechanics of a Vibratory Feeder

- Types of Vibratory Parts Feeders

- Bowl Feeders

- Linear Feeders

- Centrifugal Feeder

- Applications of Component Feeders Across Different Industries

- Automotive Manufacturing

- Electronics & Medical Equipment

- Plastic and Metal Processing

- Pharmaceutical Industry

- Benefits of Using Vibratory Parts Feeders

- Increased Efficiency

- Precision and Accuracy

- Cost-Effectiveness in the Long Run

- Choosing the Right Parts Feeder System for Your Needs

- Considerations for Selecting a Feeder

- Why Size, Shape, and Material Matter

- Common Problems with Parts Feeder Systems

- Jamming and Blockages

- Wear and Tear

- System Calibration Issues

- Conclusion: Why a Component Feeder is Essential for Your Operations

- Final Thoughts on Vibratory Parts Feeders

- Optimizing Your Automation System with the Right Feeder

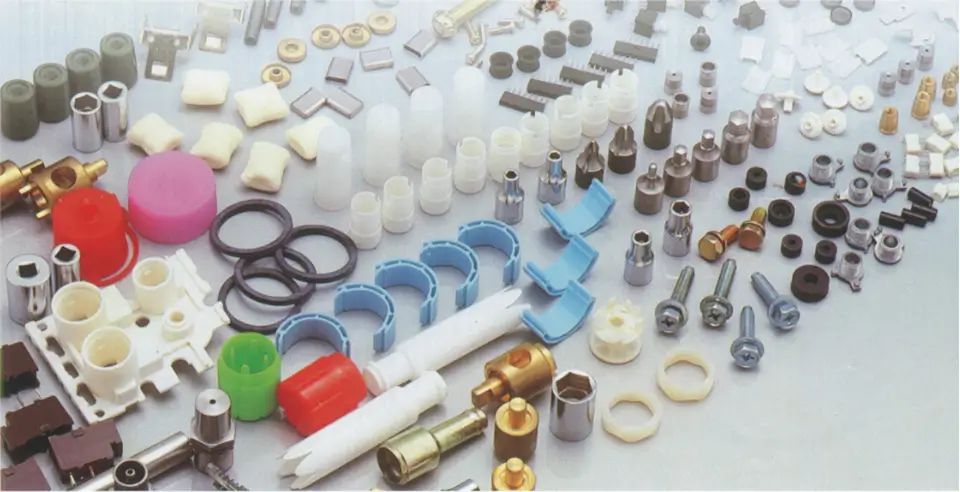

When it comes to automated systems in industries like automotive manufacturing, electronics, and pharmaceuticals, one of the unsung heroes is the component feeder. But what exactly is a component feeder, and why is it essential for streamlined operations? Simply put, component feeders are devices designed to organize, sort, and feed small parts into an assembly line or machinery, improving the efficiency of processes across various sectors. From tiny screws in automotive assembly lines to delicate medical equipment parts, vibratory parts feeders play a crucial role in delivering the right parts at the right time. Let’s explore why these systems are integral to your business’s operations.

The Role of Component Feeders in Automation

In today’s fast-paced manufacturing world, automation is a game-changer. Component feeders are at the heart of many automated systems. Without them, manufacturers would struggle to maintain smooth, consistent production. These feeders move parts from one location to another and ensure that the right part is presented in the right orientation and position for further processing or assembly. Feeders allow machines to work more efficiently, reduce human error, and maintain production speed.

What is a Vibratory Parts Feeder?

At the core of most automated assembly lines, you’ll find the vibratory parts feeder. This system uses vibrations to move and orient parts, making it a highly efficient solution for feeding small components into the correct position. But how exactly does it work? Let’s break it down:

How Vibratory Feeders Work

Vibratory feeder works by using controlled vibrations to move parts through a bowl or trough, directing them towards a specific point. This process is often aided by gravity, and the parts are carefully oriented as they move along. The feeder’s vibration rate and amplitude can be adjusted to ensure the right speed and accuracy.

The Mechanics of a Vibratory Feeder

The vibratory feeder is powered by an electromagnet that generates controlled oscillations. The parts within the feeder bowl are subjected to these oscillations, which move them in a uniform direction. As the parts travel, they align themselves in a specific orientation, making them ready for further assembly or processing. This movement is efficient, quick, and precise, which is why vibratory feeders are favored in automation systems.

Types of Vibratory Parts Feeders

Not all vibratory feeders are the same, though. Depending on your needs, you may require different types of feeders. Let’s take a look at the most common ones:

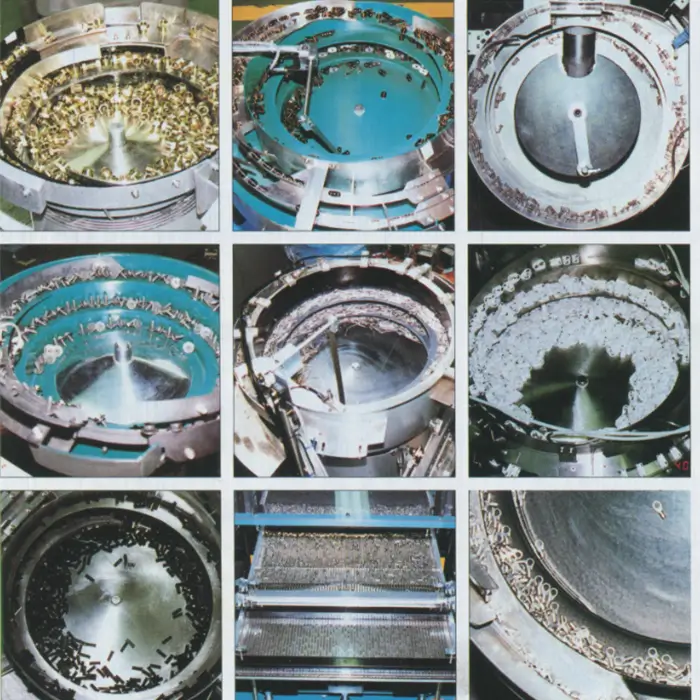

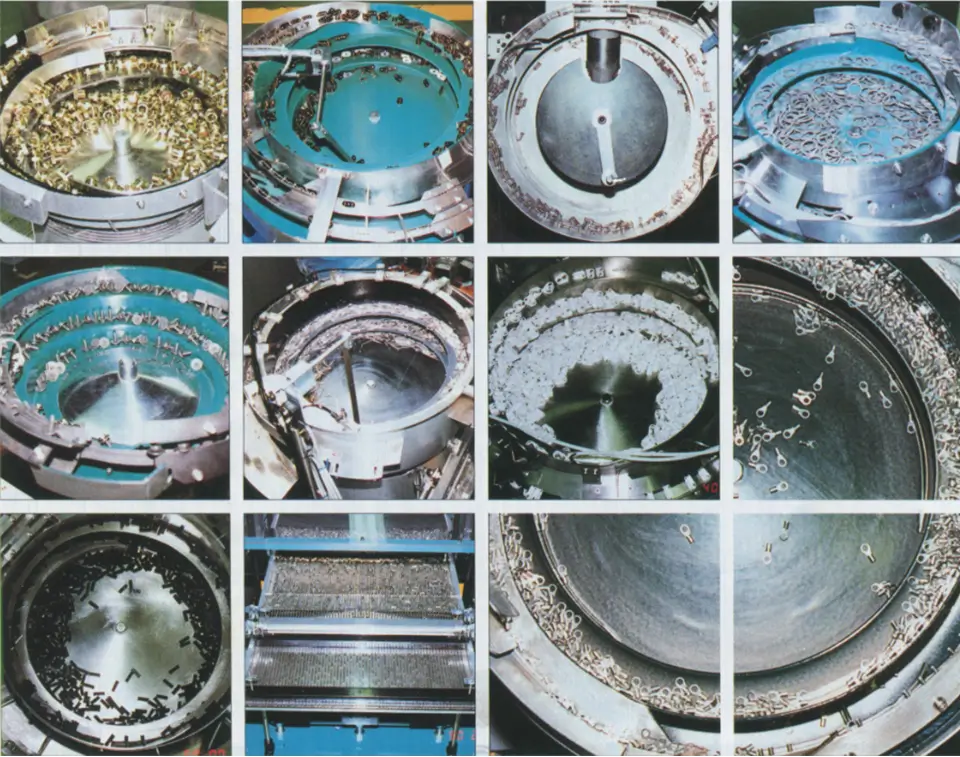

Bowl Feeders

Bowl feeders are one of the most widely used types. As the name suggests, they have a circular bowl that vibrates to move parts. Bowl feeders are highly versatile and can handle a variety of parts in different sizes and materials.

Linear Feeders

Linear feeders are often used when parts need to be transferred along a straight path rather than in a circular motion. They are excellent for longer feeding distances and are frequently employed in packaging and sorting systems.

Centrifugal Feeders

Centrifugal feeders are designed to move parts with high speed over longer distances. These feeders use centrifugal force to spin parts into specific paths. Unlike vibratory feeders, which use vibrations, centrifugal feeders rely on high-speed spinning to sort and align parts for further processing. They are ideal for handling high volumes of small or lightweight parts and are often used in industries like automotive manufacturing and electronics.

Applications of Component Feeders Across Different Industries

Let’s now dive into some of the key industries where component feeders are used. Whether it’s automotive manufacturing or pharmaceutical production, the versatility of parts feeder systems is remarkable.

Automotive Manufacturing

In the automotive industry, vibratory feeders are used to handle parts like screws, nuts, washers, and more. These parts are fed into assembly stations, where they’re automatically placed into the right position for assembly. The precision and speed of these feeders help ensure that car manufacturers meet production deadlines and maintain quality control.

Electronics & Medical Equipment

In electronics and medical device manufacturing, precision is critical. Small parts like connectors, chips, and screws are fed into automated machines using vibratory feeders. This ensures that the parts are oriented correctly and arrive at the right time, preventing delays and minimizing errors in sensitive manufacturing processes.

Plastic and Metal Processing

In plastic and metal processing, parts need to be sorted and fed into machines for further shaping, molding, or assembly. Vibratory feeders are perfect for these tasks, offering a reliable and efficient solution that minimizes downtime and improves throughput.

Pharmaceutical Industry

For the pharmaceutical industry, feeders must meet strict cleanliness standards and precise part handling. Vibratory feeders help transport small components like tablet caps, bottles, and syringes through the production line, ensuring a smooth and sterile production process.

Benefits of Using Vibratory Parts Feeders

So, why should you invest in a vibratory parts feeder system? Here are some key benefits that make these systems so popular:

Increased Efficiency

With a vibratory feeder system in place, you can increase production speed and reduce manual labor. Since the feeders are automated, there’s less need for human intervention, allowing your operators to focus on higher-value tasks.

Precision and Accuracy

Vibratory feeders are designed to handle parts with high precision. Whether it’s small electronic components or intricate medical device parts, these feeders ensure that parts are presented in the right orientation and at the correct speed.

Cost-Effectiveness in the Long Run

While there may be an initial investment in a vibratory feeder system, the cost savings over time are significant. By automating the feeding process, you reduce errors, increase throughput, and minimize the need for manual labor, which translates to lower operational costs in the long run.

Choosing the Right Parts Feeder System for Your Needs

Not all parts of feeder systems are created equal. To get the most out of your investment, you need to choose the right system for your operation. Here are some factors to consider:

Considerations for Selecting a Feeder

Think about the size, shape, and material of the parts you need to feed. Will they be fed into a bowl, linear, or centrifugal feeder system? Do you need a high-speed system or one that focuses on precision?

Why Size, Shape, and Material Matter

The size and shape of the parts you need to feed will determine the type of feeder you choose. Similarly, the material of the parts affects the design of the feeder. For example, small and delicate parts like screws or pills require a different system compared to larger, heavier items like nuts or bolts.

Common Problems with Parts Feeder Systems

Like any piece of machinery, parts feeder systems are not without their issues. Here are some common problems that you may encounter:

Jamming and Blockages

One of the most common issues with vibratory feeders is jamming. This can occur when parts become misaligned or when the feeder is overloaded. Regular maintenance and proper calibration can help avoid this problem.

Wear and Tear

Over time, the feeder components can wear down, especially if they’re handling a high volume of parts. It’s important to perform routine inspections and replace parts as needed to ensure the feeder remains in optimal condition.

System Calibration Issues

Calibrating a feeder system is crucial to maintaining its precision and speed. If the system is miscalibrated, it could result in parts being fed at the wrong speed, or orientation, or even failing to feed altogether. Routine calibration checks are key to keeping the system running smoothly

Conclusion: Why a Component Feeder is Essential for Your Operations

In conclusion, component feeders, especially vibratory parts feeders, are invaluable tools in modern automation. They help streamline operations, increase efficiency, and reduce costs, making them a must-have for industries like automotive, electronics, medical equipment, and pharmaceuticals.

Final Thoughts on Vibratory Parts Feeders

No matter the industry, the right parts feeder system can make all the difference. By investing in the right feeder and maintaining it well, you can ensure that your production processes run smoothly and efficiently.

Optimizing Your Automation System with the Right Feeder

When choosing a parts feeder system, it’s crucial to consider your unique needs. By selecting the right type of feeder and ensuring proper maintenance, you’ll be setting yourself up for success in the long term.

Contact Us

SWOER is a top 3 Chinese manufacturer specializing in the production of vibrating feeders, centrifugal feeders, and flexible feeders.