مقدمة

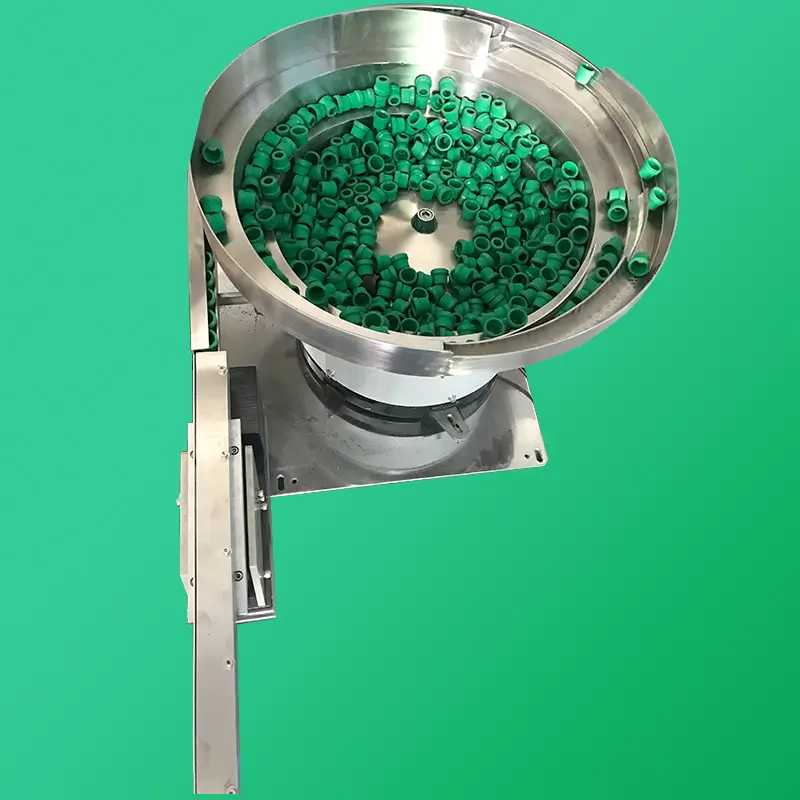

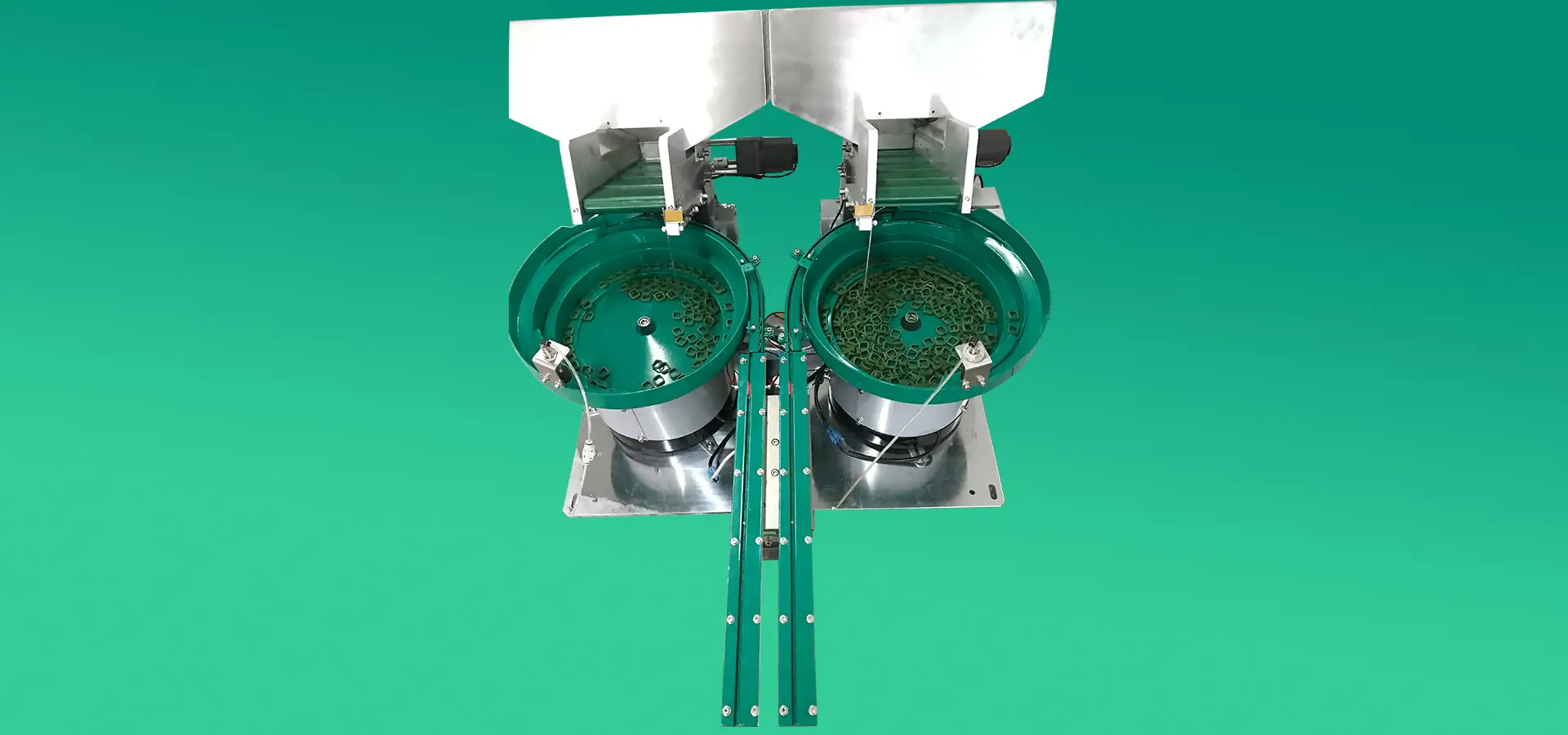

يُعدّ المغذي الخطي ذو الوعاء الاهتزازي مكونًا أساسيًا في الأنظمة الآلية، إذ يضمن تغذية سلسة للأجزاء في صناعات مثل السيارات والإلكترونيات والأدوية. ومع ذلك، عند توقفه عن العمل، يحدث تأخير في الإنتاج وانخفاض في الكفاءة. إن فهم الأسباب الشائعة وكيفية حلها يضمن سير العمليات بسلاسة. يغطي هذا الدليل الأسباب الرئيسية التي قد تؤدي إلى تعطل المغذي الخطي ذو الوعاء الاهتزازي لديك وكيفية إصلاحها.

الاتصال بين السياج وجسم المغذي الخطي

من أكثر أسباب تعطل وحدة التغذية الخطية شيوعًا التداخل بين ألواح الذيل (أو الأسوار) وجسم وحدة التغذية. في حين أن بعض الطُرز لا تحتوي على أسوار، يجب محاذاة الطُرز التي تحتوي عليها بشكل صحيح لمنع العوائق.

حل:

- تأكد من أن السياج يلامس جسم المغذي الخطي.

- قم بضبط السياج للحفاظ على فجوة مناسبة للحركة السلسة.

- قم بفحص السياج وإعادة محاذاته بشكل منتظم لمنع تكرار المشاكل.

الاتصال بين السياج وجسم المغذي الخطي

من أكثر أسباب تعطل وحدة التغذية الخطية شيوعًا التداخل بين ألواح الذيل (أو الأسوار) وجسم وحدة التغذية. في حين أن بعض الطُرز لا تحتوي على أسوار، يجب محاذاة الطُرز التي تحتوي عليها بشكل صحيح لمنع العوائق.

حل:

- تأكد من أن السياج يلامس جسم المغذي الخطي.

- قم بضبط السياج للحفاظ على فجوة مناسبة للحركة السلسة.

- قم بفحص السياج وإعادة محاذاته بشكل منتظم لمنع تكرار المشاكل.

مشاكل المسار في المغذي الخطي

يؤثر تصميم المسار ووزنه بشكل كبير على أداء وحدة التغذية. إذا كان المسار سميكًا أو ثقيلًا جدًا، فقد تفتقر وحدة التغذية إلى الطاقة اللازمة للعمل بكفاءة. كما أن سوء التركيب قد يؤدي إلى فقدان الطاقة، مما يجعل وحدة التغذية غير فعالة.

حل:

- تأكد من أن وزن المسار يقع ضمن سعة المغذي.

- تجنب السُمك الزائد في تصميم المسار لمنع فقدان الطاقة.

- استخدم مسامير التثبيت ذات الحجم المناسب لتجنب التداخل مع المغناطيس الكهربائي أو المحرك.

مشاكل الدائرة الكهربائية

تُعد الأعطال الكهربائية سببًا شائعًا آخر لتعطل وحدة التغذية. قد يؤدي فصل موصلات الطيران أو توصيلات الطرفية إلى انقطاع تدفق الطاقة، مما يؤدي إلى توقف التشغيل تمامًا.

حل:

- افحص جميع التوصيلات الكهربائية بحثًا عن المقابس أو المحطات الكهربائية الفضفاضة.

- قم بتأمين أي أسلاك منفصلة واختبار الدائرة للتأكد من استمراريتها.

- قم بفحص مصدر الطاقة بشكل منتظم للتأكد من التشغيل المتواصل.

نصائح الصيانة الوقائية

لتجنب الأعطال غير المتوقعة، يُعدّ تطبيق جدول صيانة دورية أمرًا ضروريًا. فالكشف المبكر عن المشاكل المحتملة يضمن تشغيل وحدة التغذية بكفاءة.

نصائح:

- إجراء عمليات تفتيش روتينية للسياج والمسارات والبراغي.

- احرص على إبقاء التوصيلات الكهربائية آمنة وخالية من الغبار أو الحطام.

- قم بتزييت الأجزاء المتحركة حسب الحاجة، مع تجنب وجود كمية زائدة من الزيت بالقرب من المغذي.

- قم باختبار المغذي بشكل دوري لاكتشاف أي مخالفات قبل أن تتحول إلى مشاكل كبيرة.

خاتمة

قد يؤدي عطل في وحدة التغذية الخطية ذات الوعاء الاهتزازي إلى تعطيل الإنتاج، إلا أن فهم الأسباب الجذرية يُساعد على استكشاف الأخطاء وإصلاحها بسرعة. معالجة مشاكل مثل تداخل السياج، وأخطاء التركيب، وعدم محاذاة المسارات، والأعطال الكهربائية تضمن التشغيل السلس. كما أن الصيانة والفحوصات الدورية تُقلل من وقت التوقف عن العمل وتُعزز الإنتاجية، مما يضمن استمرار عمليات الأتمتة دون انقطاع.

لماذا تختار وحدة تغذية الأوعية الاهتزازية SWOER؟

في حين أن العديد من مغذيات الأوعية الاهتزازية الخطية تواجه هذه المشاكل الشائعة، فإن مغذيات SWOER المصممة بدقة عالية مصممة لتدوم طويلاً. صُممت مغذياتنا وفقًا لمعايير الجودة الأوروبية، وتخضع لاختبارات صارمة لضمان أداء مثالي. وقد استخدم العديد من عملائنا الأوروبيين مغذيات SWOER الاهتزازية لسنوات دون مواجهة هذه المشاكل، بفضل تصميمنا المتطور وموادنا عالية الجودة ورقابة الجودة الصارمة.

إذا كنت تبحث عن حل تغذية اهتزازية موثوق يقلل من وقت التوقف ويعزز الكفاءة، فنحن هنا لمساعدتك. تواصل معنا اليوم لمناقشة متطلباتك الخاصة - املأ النموذج أدناه، وسيتواصل معك فريقنا في أقرب وقت!