Vibratory Bowl vs. Flexible Feeder – Which is Better?

There is no universal “better” solution. The choice depends entirely on your specific application, part characteristics, production volume, and budget.

| Aspect | Vibratory Bowl | وحدة تغذية مرنة |

|---|---|---|

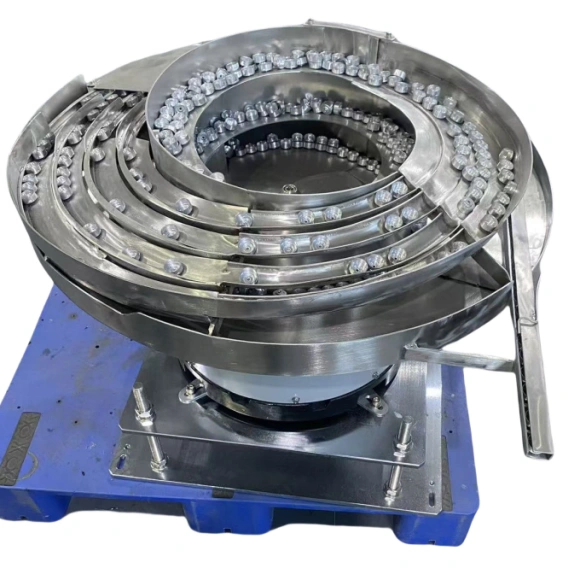

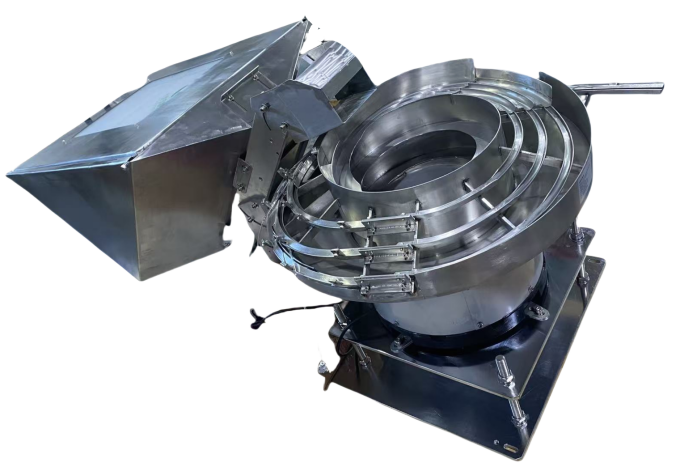

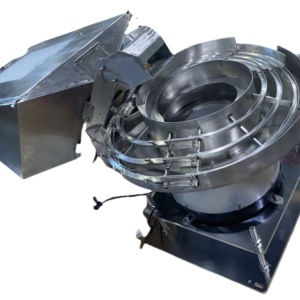

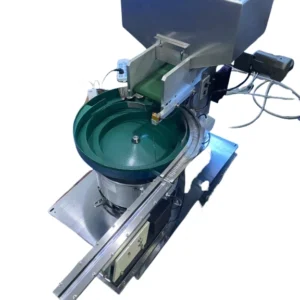

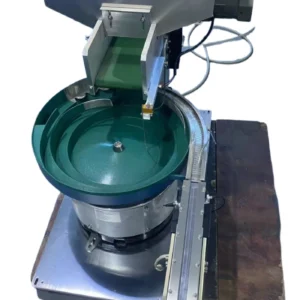

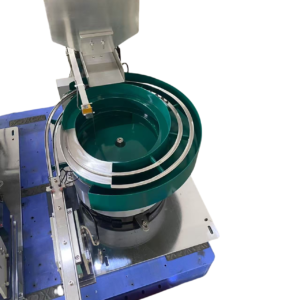

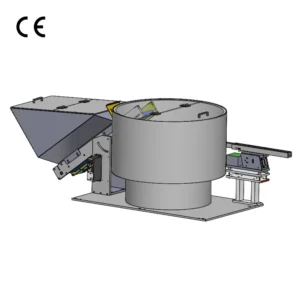

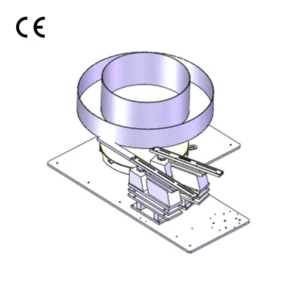

| Core Principle | Mechanical Sorting. Forces parts into orientation via vibration and track tooling. | Vision-Guided Intelligence. Scatters parts, uses a camera to locate them, and guides a robot to pick. |

| Ideal Parts | Regular, sturdy, non-tangling parts (screws, washers, standard components). | Virtually any part. Excels with tangle-prone, delicate, complex, asymmetric parts (springs, O-rings). |

| Production Volume | High-volume, low-mix. Changeover is slow (physical retooling). | Low-volume, high-mix. Changeover is fast (minutes, software change only). |

| سرعة | Very High. Can feed thousands of suitable parts per minute. | Medium to High. Limited by vision/robot cycle time. More stable. |

| Initial Cost | Relatively Low. Cost is in custom mechanical tooling. | Very High. Requires investment in vision, robot, software, platform. |

| Long-Term Cost | Higher changeover cost, simpler maintenance. | Near-zero changeover cost, more complex maintenance. |

| المرونة | Very Low. Dedicated to one/few part types. | Extremely High. Adapts via software. |

| Part Damage Risk | Possible due to friction/impact. | Minimal. Very gentle process. |

| مستوى الضوضاء | High (vibration & part collision). | Low (motors & air only). |

Decision Guide: Ask Yourself:

Are my parts tangle-prone, delicate, or complex in shape?

YES -> وحدة تغذية مرنة is strongly preferred.

NO -> Both are options.

Is my production high-volume/low-mix or low-volume/high-mix?

High-volume, few products -> Vibratory Bowl wins on cost and speed.

Frequent changeovers -> Flexible Feeder’s flexibility is invaluable.

What is my budget?

Tight budget & conditions from 1 & 2 fit -> Vibratory Bowl.

Ample budget & seeking future-proof flexibility -> وحدة تغذية مرنة.

Final Advice: If you handle standard fasteners in high-volume, long-run production, the vibratory bowl is the cost-effective king. If you face challenges with rapid product iteration, complex, or delicate parts, the flexible feeder is an investment in future-proof flexibility.

المراجعات

لا توجد مراجعات بعد.