Intro:

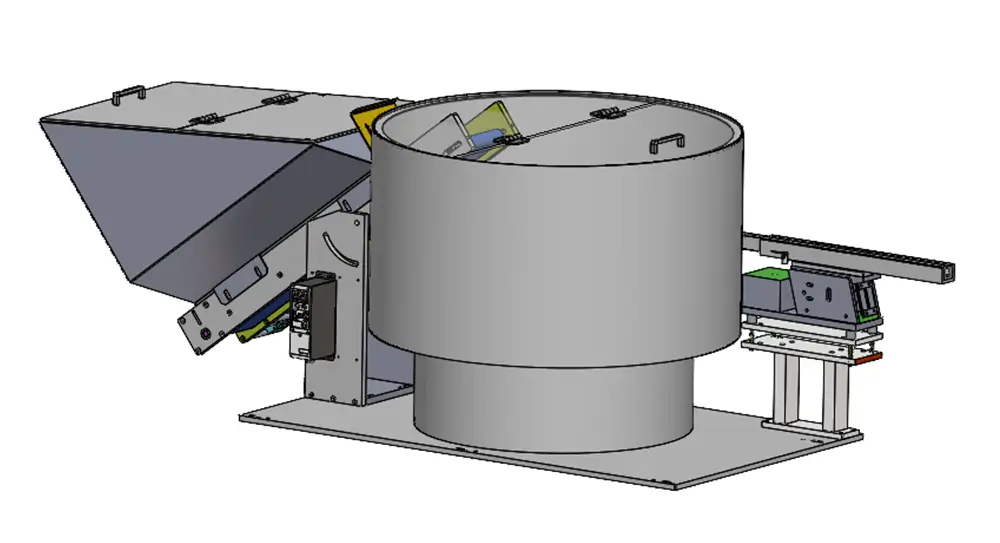

Vibratory bowl feeders are an indispensable tool in modern manufacturing, providing efficient parts handling and orientation. However, like any piece of machinery, they can experience problems that disrupt production. In this troubleshooting guide, we’ll look at some common problems with vibratory disk feeders and offer solutions.

Bowl feeder not starting:

One of the most common problems is a bowl feeder that fails to start. This can be due to a number of reasons, such as a loose connection, a faulty power supply or a faulty control unit. To fix this problem, first check the power supply and make sure it is properly connected. Next, check the control unit for any signs of damage or malfunction. If necessary, consult the manufacturer’s manual for troubleshooting procedures or contact technical support for assistance.

Parts stuck or sticking:

Another common problem is parts getting stuck or sticking inside the feed bowl. This can occur if parts are not properly aligned or if there is excessive friction between the part and the bowl surface. To resolve this issue, check the feeder bowl for any obstructions or misalignment. Adjust the feeder settings as needed to ensure smooth part movement. Also, consider applying a lubricant to the drum surface to minimize friction and prevent parts from sticking.

Uneven part distribution:

Uneven part distribution within the feeder bowl can lead to inefficiencies and production delays. This problem can occur due to incorrect feeder settings, worn components, or irregular part shapes. To address uneven part distribution, first, check the feeder settings and make adjustments to achieve a more balanced distribution. If necessary, replace any worn components or consider upgrading to a feeder with adjustable features to accommodate irregular part shapes.

Excessive noise or vibration:

Excessive noise or vibration from a vibratory disk feeder may indicate an underlying problem, such as loose components, misalignment or worn parts. To alleviate this problem, thoroughly inspect the feeder assembly and tighten any loose components. Ensure that all components are properly aligned and replace any worn or damaged parts as needed. In addition, consider installing dampening materials to reduce noise and vibration levels.

SWOER specializes in designing and manufacturing vibratory bowl feeders, offering customized options with soundproof covers to address noise issues during operation.

Conclusion:

Vibratory bowl feeders are valuable assets in manufacturing operations, but they can experience common problems that impact productivity. By following the troubleshooting steps outlined in this guide, manufacturers can effectively address these issues and maintain optimal performance of their vibratory bowl feeders. For more in-depth assistance, consult the manufacturer’s manual or contact SWOWER Technical Support for personalized guidance.

Contact Us