Introduction to Vibratory Bowl Feeders

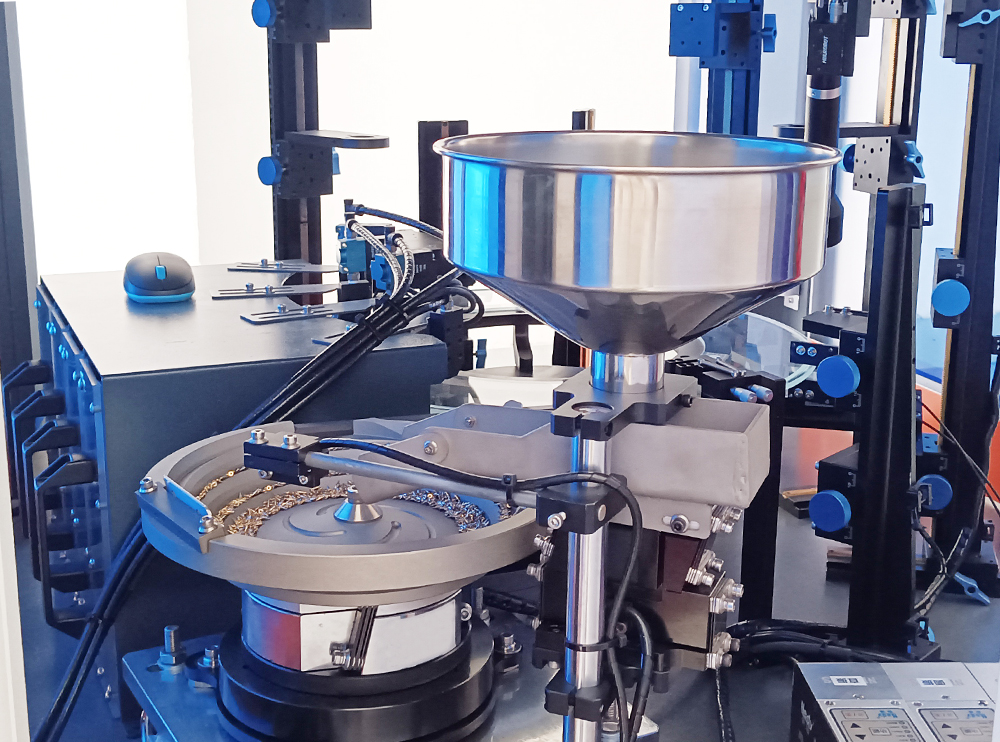

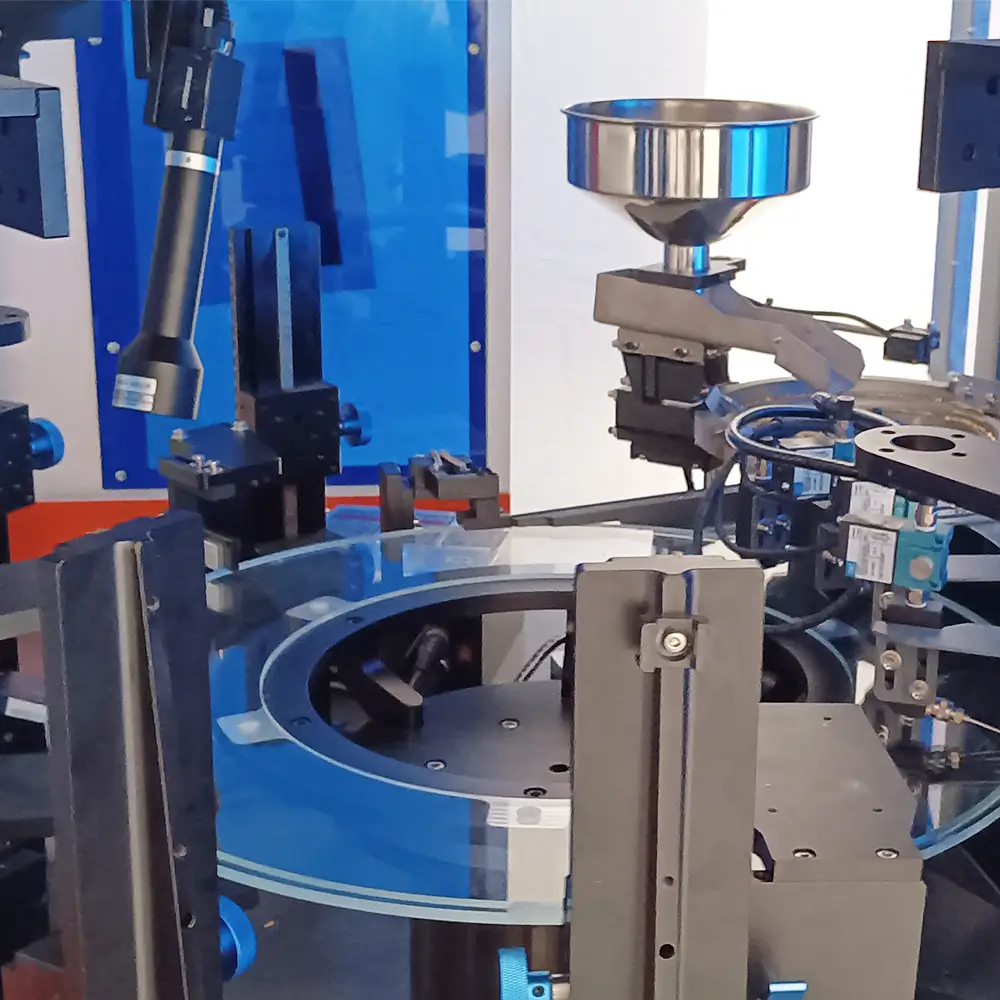

Vibratory bowl feeders are essential in today’s manufacturing plants, making it easier to handle and align small to medium-sized parts efficiently. Whether they’re part of assembly lines, packaging setups, or quality control procedures, these adaptable tools provide a dependable solution for optimizing production processes and improving overall efficiency.

Grasping the Significance of Vibratory Bowl Feeders in Manufacturing

Vibratory bowl feeders are crucial for automating repetitive tasks in parts handling, cutting down on labor expenses, and minimizing errors that come with manual sorting and feeding. Using vibration, these machines quickly align and transport parts along a set path, ensuring seamless and uninterrupted operation in the factory.

Key Factors to Consider When Selecting a Vibratory Bowl Feeder

When selecting a vibratory bowl feeder for your business, it’s vital to weigh several crucial factors to ensure it fits your unique production needs and sets you up for long-term success. These factors encompass the types and sizes of parts you’ll handle, desired feed rates, space availability, budget considerations, and the reputation of the manufacturer.

Assessing Your Business Needs

Identifying Your Specific Production Requirements

Begin by analyzing your factory’s production processes to determine the role the vibratory bowl feeder will play. Consider factors such as production volume, part complexity, and desired throughput rates. Understanding your unique production requirements will help you narrow down your options and focus on solutions that best meet your needs.

Evaluating the Types and Sizes of Parts to be Handled

Take inventory of the parts that will be fed through the vibratory bowl feeder. Consider the size, shape, weight, and material composition of these parts, as well as any special handling requirements. This information will influence the design and configuration of the feeder, ensuring optimal performance and part compatibility.

Determining Your Budget and Return on Investment (ROI) Expectations

Establish a clear budget for purchasing and implementing a vibratory bowl feeder, taking into account both upfront costs and long-term operational expenses. Consider the potential ROI that the feeder will deliver in terms of labor savings, increased productivity, and improved product quality. Balance your budgetary constraints with your expectations for ROI to make an informed investment decision.

Understanding Vibratory Bowl Feeder Types and Configurations

Bowl Shape and Size Options

Vibratory bowl feeders are available in various bowl shapes and sizes to accommodate different part geometries and handling requirements. Common shapes include conical, cylindrical, and stepped bowls, each offering unique advantages for specific applications. Choose a bowl shape and size that best suits the size and shape of your parts, ensuring optimal feeding performance.

Single or Multiple Track Designs

Depending on your production needs, you may opt for a vibratory bowl feeder with a single track or multiple tracks. Single-track feeders are ideal for handling one type of part at a time, while multiple-track feeders can handle multiple part types simultaneously, increasing throughput and versatility. Consider your production volume and part diversity when selecting the appropriate track configuration.

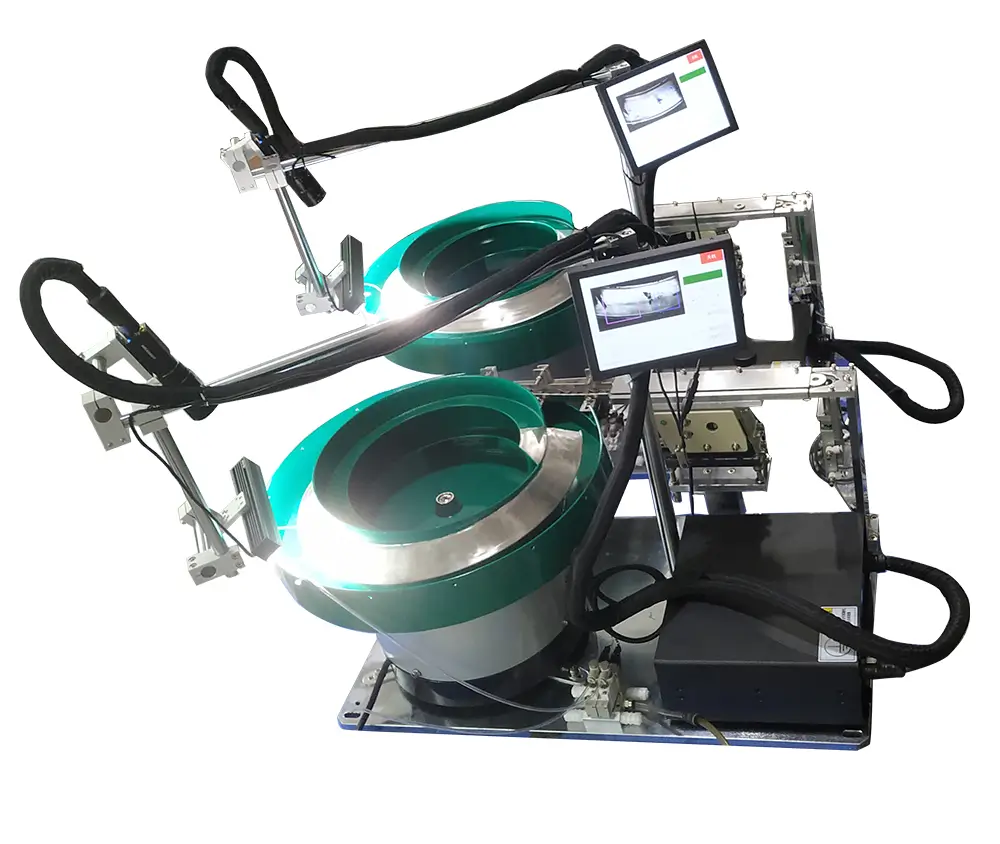

Can it be used with CCD vision system?

CCD visual systems are integral components in vibratory bowl feeders, particularly in modern manufacturing environments. These systems employ advanced imaging technology to enhance the accuracy and efficiency of part orientation and tracking. By capturing high-resolution images of parts as they move along the feeder track, CCD visual systems ensure precise alignment and delivery. This not only streamlines production processes but also minimizes errors and enhances overall quality control. Additionally, CCD visual systems can be seamlessly integrated with other automation technologies, providing manufacturers with a comprehensive solution for optimizing their assembly lines and maximizing productivity.

SOWER Company excels in combining vibratory bowl feeder technology with CCD visual systems. This unique capability allows for precise part orientation and tracking, ensuring seamless production processes and enhanced quality control. By harnessing the power of vibratory bowl feeders alongside advanced CCD visual technology, SOWER provides manufacturers with comprehensive solutions that optimize efficiency and productivity in modern manufacturing environments.

Coatings and Surface Treatments for Different Applications

Some vibratory bowl feeders feature specialized coatings or surface treatments to enhance part handling and prevent damage or contamination. For example, coatings such as polyurethane or Teflon can improve part flow and reduce friction, while surface treatments like anodizing or passivation can provide corrosion resistance for parts in harsh environments. Choose a feeder with the appropriate coating or treatment for your application to ensure optimal performance and part integrity.

Evaluating Manufacturer Reputation and Support

Researching and Comparing Different Manufacturers

Take the time to research and compare different vibratory bowl feeder manufacturers to find a reputable and reliable supplier. Consider factors such as industry experience, product quality, customer reviews, and technical expertise when evaluating manufacturers. Look for manufacturers with a proven track record of delivering high-quality products and excellent customer support.

Assessing Warranty, Maintenance, and Technical Support Services

Review the warranty, maintenance, and technical support services provided by various manufacturers to guarantee peace of mind and continuous assistance throughout the lifespan of your vibratory bowl feeder. Seek out manufacturers offering extensive warranty coverage, proactive maintenance plans, and prompt technical support to address any operational issues or concerns. Additionally, consider the availability of spare parts, repair services, and training programs to ensure uninterrupted productivity and minimal downtime.

SWOER offers warranty, maintenance, and online video technical support services to ensure your peace of mind and continuous assistance throughout the entire lifespan of your vibratory bowl feeder. We’re committed to promptly addressing customer inquiries, and ensuring swift resolution of any issues.

Contact Us