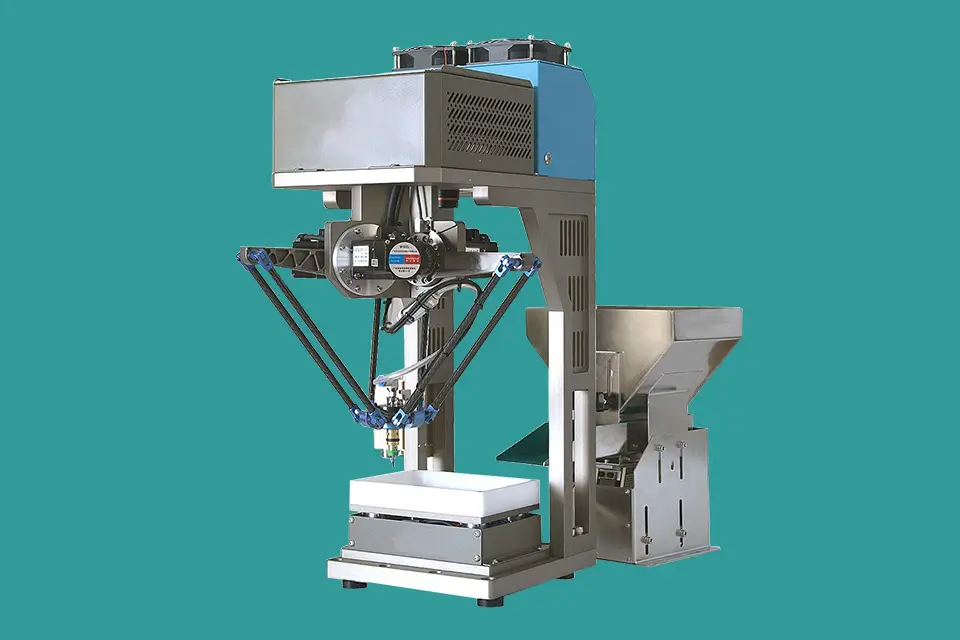

A flexible feeder system, also known as a flex feeder, flexible part feeder, or robotic pick and place system, efficiently handles special-shaped parts ranging from 0.1mm to 150mm.

Why Choose a Flexible Feeder System?

Industries like automotive, insert injection molding, and watch ceramics demand high precision. Traditional vibratory feeders struggle with irregular parts, making automation difficult. SWOER’s flexible visual material selection system solves these challenges, ensuring efficient, damage-free feeding.

Key Advantages:

Protects Delicate Electroplated Parts Traditional vibratory feeders cause parts to scratch as they circulate in the bin. Our flexible feeder eliminates reciprocating feeding, ensuring scratch-free handling.

Handles Special-Shaped Workpieces Standard feeders rely on geometric shapes and mass distribution for sorting. They fail with irregular parts. Our vision-based system identifies and selects parts with precision, solving this issue.

Advanced Automation for Precision Industries

CN SWOER CO., LTD specializes in developing flexible vibratory visual feeding systems. Our SW series flexible feeders integrate visual positioning and robotic grasping to meet modern automation demands. These systems enable quick production switches for small-batch, multi-variety manufacturing while addressing common vibratory feeder challenges like noise, complex part separation, and feature recognition.

Increasingly adopted in high-precision fields—including aerospace, military, 3C electronics, automotive electronics, and watch ceramics—our flexible feeders provide a smarter, more adaptable solution for automated production.

Contact Swoer

Get flexible feeding system design.