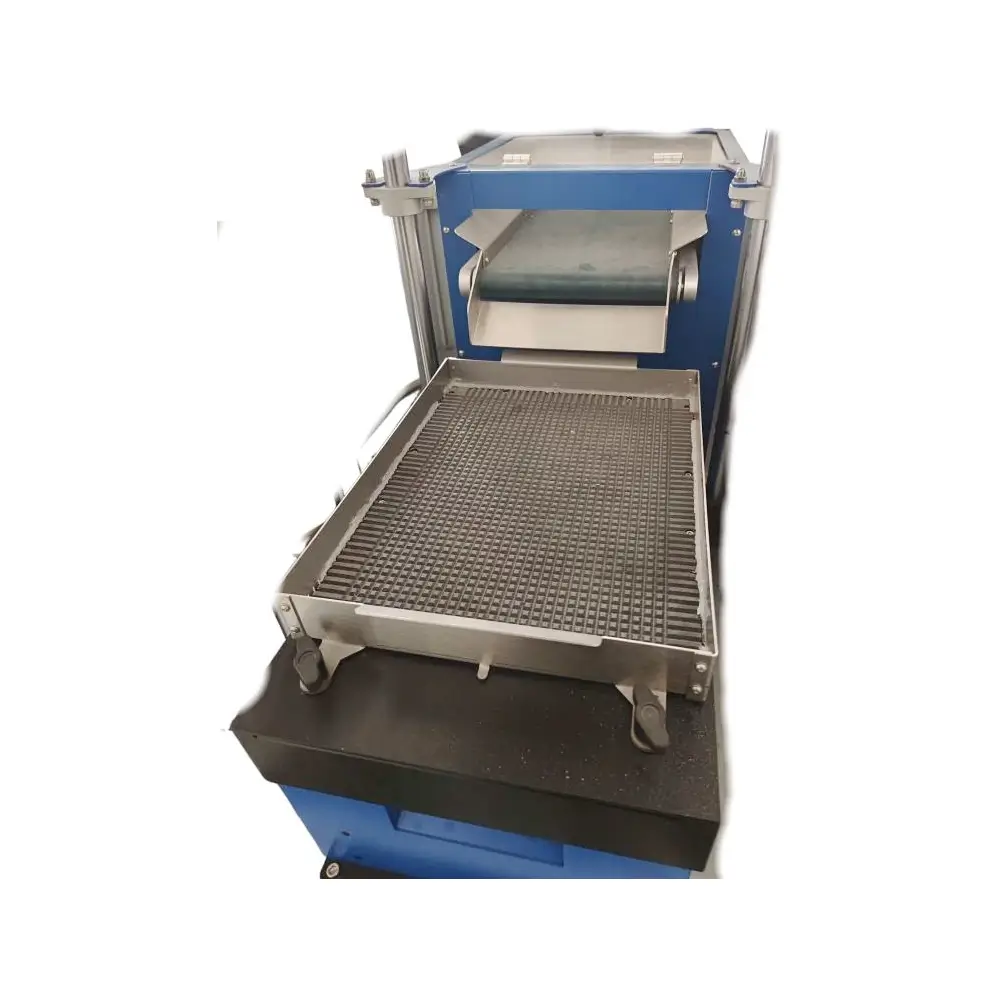

EV-DVI-100 Flex Feeder and Robot-integrated Machine

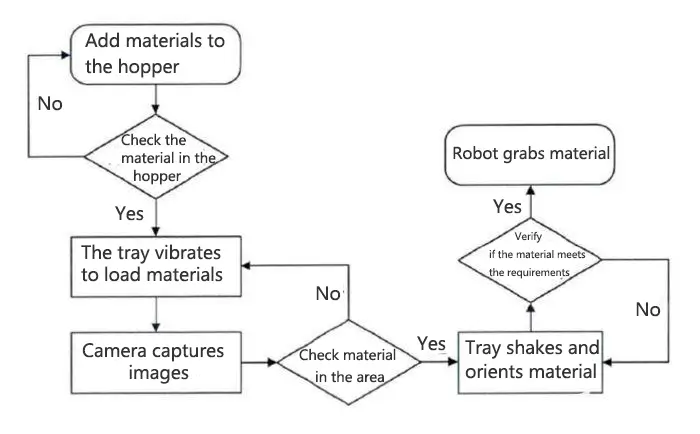

Working Principle of Flexible Feeder

The flexible feeder generates vibrations through the voice coil motor, which causes the material to vibrate on the plate. This vibration enables the material to be activated(easy to move) and move in a specific direction. The flexible feeder uses the principle of resonance and interference of coherent waves to move the material in a certaindirection and form an arrangement. By controlling the vibration frequency and vibration direction of the voice coil motor, the material can be transported directionally. Automatic separation and arrangement: During the vibration process, the materials will be automatically separated and arranged according to their weight,shape, and size differences. This automatic separation and arrangement function helps to achieve fast and accurate material distribution.

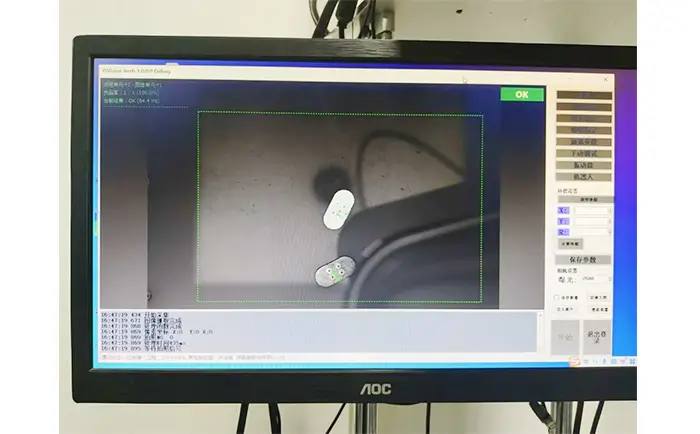

Visual Recognition and Control System

Flexible feeders are usually equipped with a CCD visual recognition system for positioning and identifying small parts. The visual system can obtain the position information of the parts and transmit it to the control system. The control system of the flexible feeder adjusts the vibration parameters of the voice coil motor, such as frequency and amplitude, according to the part position information to achieve

accurate material delivery. At the same time, the control system can also control the movement of the manipulator (robot) to ensure that it accurately grabs the parts.

Visual System Screening Diagram

Robotic Grabbing

The flexible feeder works with the robot to adjust the robot’s posture based on the part position information, enabling automated, unmanned feeding operations. When the robot grabs the part, the flexible vibration plate stops vibrating to ensure the stability and accuracy of the grab. The robot’s suction nozzle can select the most suitable one according to the specific shape of the material. The robot’s suction nozzle operates at a height of 90cm to 100cm.

Robot Physical Picture

Nozzle Actual Picture

Solution Advantages

- Improve Efficiency

The flexible feeder ensures fast, precise part arrangement, boosting production line automation and efficiency.

- Reduce Costs

With its simple structure and ease of maintenance, the flexible feeder lowers production costs and enhances economic benefits.

- Enhance Quality

The flexible feeder accurately controls part positioning, eliminating manual errors, and improving product quality.

Application Industry

Flexible feeders are also widely used in the following scenarios:

- Electronic Manufacturing: Flexible feeders improve production efficiency by automating feeding, arranging, and assembling.

- Food and Drug Industry: They ensure product hygiene and quality through automatic feeding and sorting of food or drugs.

- Medical Device Industry: Flexible feeders automate the feeding and arranging of small parts, such as surgical instruments and dental equipment.

Illustrations of Parts in Some Industries

- Electronic Components (e.g., resistors, capacitors, ICs, connectors)

- Automotive Parts (e.g., bolts, nuts, clips, washers)

- Plastic Parts (e.g., molded plastic components)

- Metal Parts (e.g., screws, pins, springs)

- Medical Devices Components (e.g., syringes, vials, medical connectors)

- Pharmaceutical Items (e.g., tablets, capsules, packaging parts)

Specifications

| Item | Standard |

| Model | EV-DVI-100 |

| Accuracy | ±0.1mm |

| UPH | ≥5000 Pcs/H |

| Flex Tray Size | In-disk 320 x 260mm, External Dimensions 440 x 270mm |

| Delivery Frequency | 1H |

| Camera | Hikvision 20MP Camera / 12MP Camera |

| Robot | Huichuan / Epson(Arm length 400mm) |

| Lighting | 400x 300 peerforated backlight |

| Control System | PC+Robot |

| Operating System | Win10, 64-bit operating system |

| Computer | Intel® Core™ i5, Intel® Q370 Chipset, 4G RAM, 128G SSD + 1T HDD |

| Outline Dimensions | L1100 * W800 * H1100mm |

| Weight | About 1200KG |

| Power | AC200V, 50Hz |

| Air Pressure | 0.5-0.7MPa |

Reviews

There are no reviews yet.