- Introduction to Step Feeders and Step Conveyors

- What Are Step Feeders?

- What Are Step Conveyors?

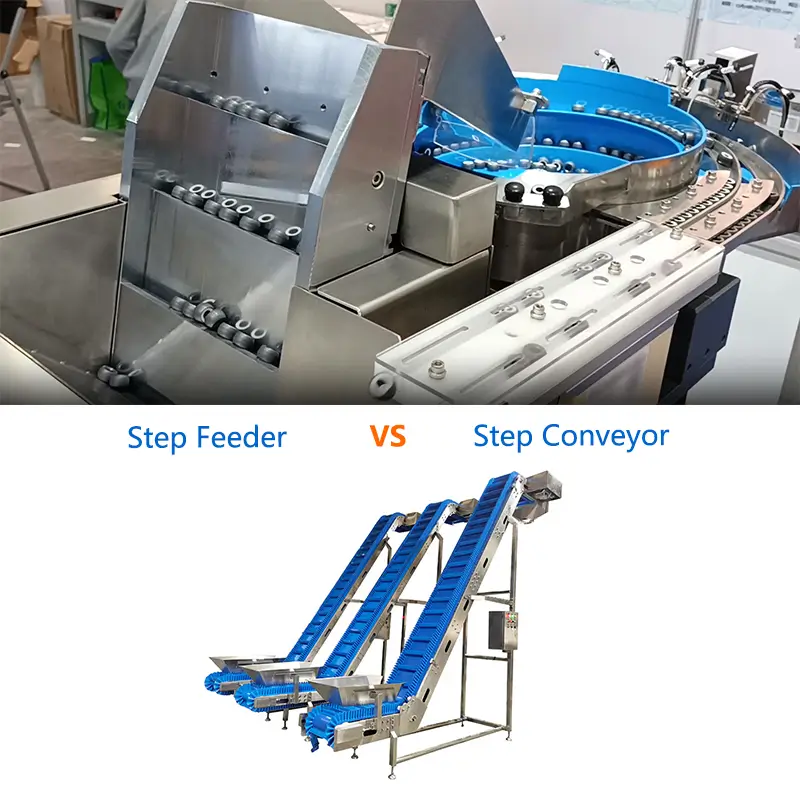

- Step Feeder vs Step Conveyor:

- A Comprehensive Comparison Functionality

- Detailed Analysis of Step Feeders

- How Step Feeders Work

- Common Applications of Step Feeders

- Advantages of Step Feeders

- Detailed Analysis of Step Conveyors

- How Step Conveyors Work

- Common Applications of Step Conveyors

- Advantages of Step Conveyors

- Choosing Between Step Feeders and Step Conveyors

- Factors to Consider

- Industry-Specific Recommendations

- Why Choose SWOER as Your Step Feeder Supplier

- Introduction to SWOER

- SWOER’s Expertise in Step Feeders

- Customisation Options Offered by SWOER

- Global Reach and Customer Support

- Conclusion

Introduction to Step Feeders and Step Conveyors

When it comes to industrial automation, efficient material handling is paramount. Two commonly used systems in modern production lines are Step Feeders and Step Conveyors. While they might sound similar, their distinct functionalities and designs cater to varying industrial needs.

What Are Step Feeders?

Step Feeders are designed to move small parts or components in a controlled manner. Their primary purpose is to elevate and position items so they can be easily integrated into an automated process. These feeders are particularly valuable in precision-driven industries such as automotive and electronics.

What Are Step Conveyors?

Step Conveyors, on the other hand, are designed to transport bulk materials or heavy items across longer distances. They operate in a segmented, step-by-step motion, ensuring stability and efficiency during the transfer process. These conveyors are ideal for industries requiring high-capacity, continuous transport of materials.

Key Differences Between Step Feeders and Step Conveyors

Understanding the key distinctions between Step Feeders and Step Conveyors is essential for selecting the right solution for your production needs. Below is a comprehensive comparison:

Feature | Step Feeder | Step Conveyor |

Functionality | Precisely feeds and orients individual small parts or components. | Transports bulk materials or heavy items over longer distances. |

Design | Features a tiered, stair-like mechanism for gradual lifting and separation. | Uses a flat or inclined surface with segmented, step-by-step motion. |

Material Type | Small, precise parts like screws, bolts, or electronic components. | Large, bulky, or heavy items such as parcels, packaged goods, or machinery parts. |

Precision | High precision, often used for automated assembly lines. | Moderate precision, focused on stability and efficient transportation. |

Load Capacity | Suitable for lightweight items. | Handles heavier loads with higher weight capacities. |

Application Examples | – Automotive: Feeding screws and fasteners. | – Logistics: Parcel transport in warehouses. |

Space Requirements | Compact and suitable for limited spaces. | Requires more space due to its conveyor length and size. |

Movement Type | Gradual, precise upward motion to position parts. | Segmented or continuous motion to transfer items across distances. |

Energy Efficiency | Low energy consumption due to compact design. | Moderate energy consumption for larger loads and distances. |

Noise Level | Operates quietly, ideal for precision industries. | Can be noisier, depending on load and speed. |

Cost | Typically lower due to smaller size and simpler applications. | Higher cost due to larger scale and heavier-duty requirements. |

Detailed Analysis of Step Feeders

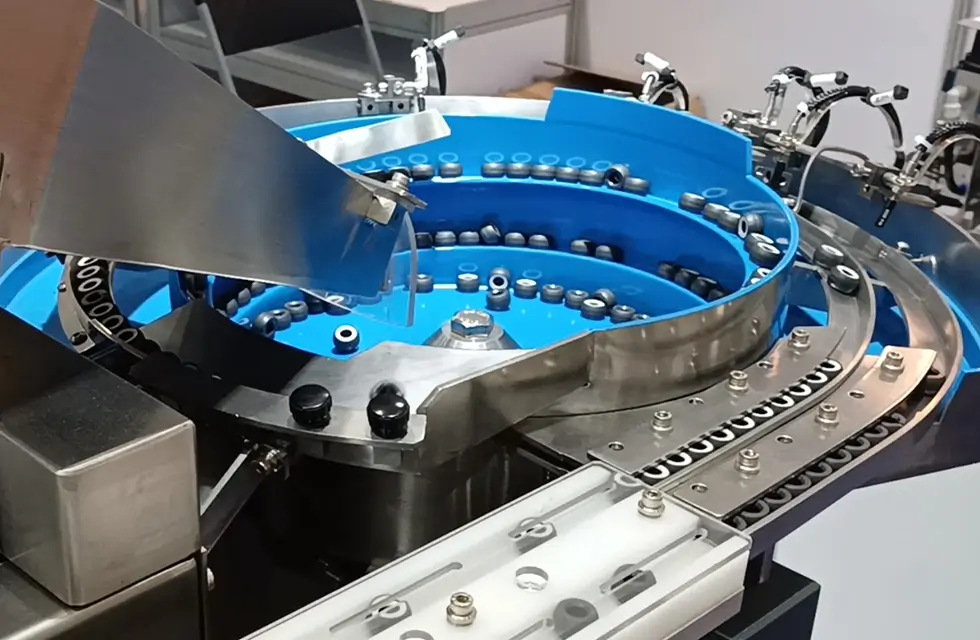

How Step Feeders Work

Step Feeders operate using a tiered platform that gradually moves items upward. The process involves:

- Part Collection:Items are loaded in bulk into the feeder.

- Separation:The steps gently lift and separate the parts.

- Positioning:Parts are delivered to the exit point in the desired orientation.

Common Applications of Step Feeders

- Automotive Industry:Feeding bolts, screws, and small components for assembly.

- Electronics Manufacturing:Positioning microchips and other sensitive parts.

- Medical Device Production:Handling small items like syringes or vials.

Advantages of Step Feeders

- High precision in feeding small items.

- Minimal wear and tear on delicate components.

- Energy-efficient operation with minimal noise.

Detailed Analysis of Step Conveyors

How Step Conveyors Work

Step Conveyors utilize a flat or inclined surface that moves in segmented steps. The process includes:

- Loading:Bulk materials are placed on the conveyor.

- Transportation:The conveyor moves the load in pre-defined intervals.

- Delivery:Items are transferred to the next stage of production.

Common Applications of Step Conveyors

- Food Processing:Moving packaged or unpackaged goods.

- Heavy Industry:Transporting metal components or construction materials.

- Logistics:Conveying parcels or containers in warehouses.

Advantages of Step Conveyors

- High load capacity.

- Suitable for long-distance transportation.

- Durable design for heavy-duty applications.

Choosing Between Step Feeders and Step Conveyors

When deciding between Step Feeders and Step Conveyors, consider the following factors:

- Type of Material:For small, precise parts, choose Step Feeders; for bulk or heavy materials, opt for Step Conveyors.

- Production Requirements:Consider the speed and precision required in your process.

- Space Availability:Step Feeders are compact, while Step Conveyors may require more space.

Industry-Specific Recommendations

- Electronics:Step Feeders for precision components.

- Logistics:Step Conveyors for efficient material transport.

Why Choose SWOER as Your Step Feeder Supplier

Introduction to SWOER

SWOER is a leading manufacturer specialising in custom vibratory feeders, step feeders, and advanced automation systems. With over 10 years of experience, SWOER is ranked among the top manufacturers in China.

SWOER’s Expertise in Step Feeders

- Precision-engineered designs tailored to your production needs.

- Proven performance in industries like automotive, electronics, and medical devices.

- Energy-efficient and durable solutions.

Customisation Options Offered by SWOER

SWOER understands that every production line is unique. That’s why we offer:

- Custom feeder sizes and configurations.

- Integration with robotics and vision systems for enhanced automation.

- Expert consultation to ensure optimal performance.

Global Reach and Customer Support

As a trusted supplier, SWOER serves clients worldwide. With a commitment to customer satisfaction, we provide:

- Quick response to inquiries.

- Comprehensive technical support.

- Reliable shipping and delivery services.

Conclusion

Choosing the right material handling solution is critical for the efficiency of your production line. Whether you require the precision of a Step Feeder or the durability of a Step Conveyor, understanding their differences will guide you to the best option.

After reading the above, do you have a general idea of whether to choose a step feeder or step feeder conveyor for your material?

Contact Us

If you still have questions, don’t hesitate to get in touch with us, Our design team will give you a solution suitable for your material.