What is a vibratory bowl feeder?

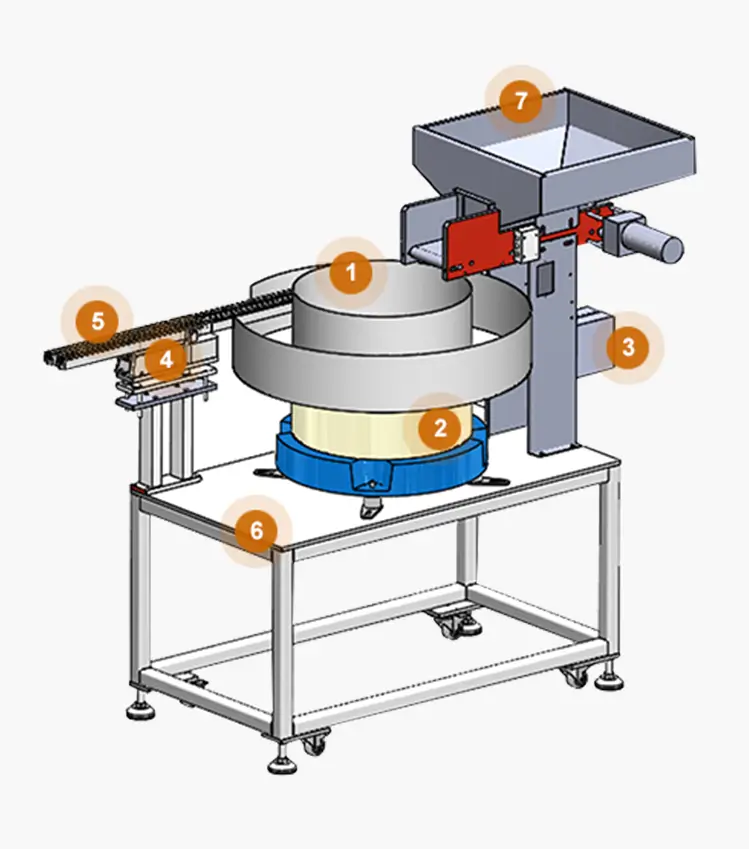

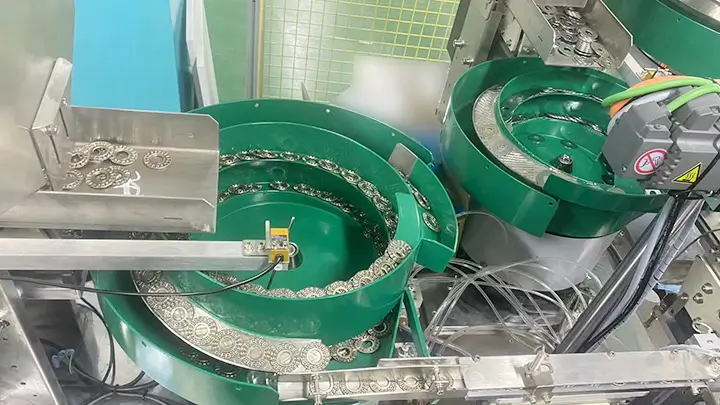

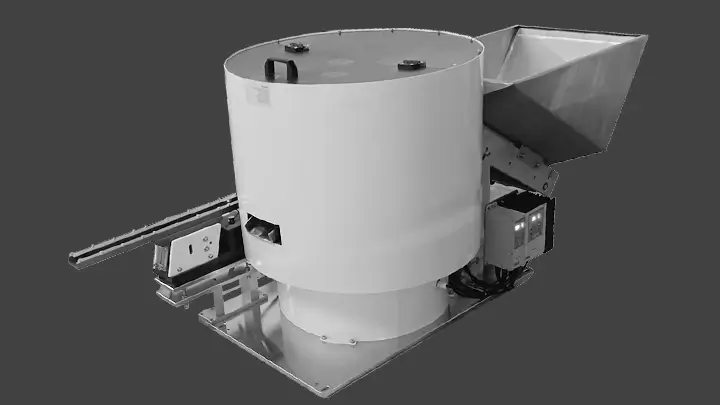

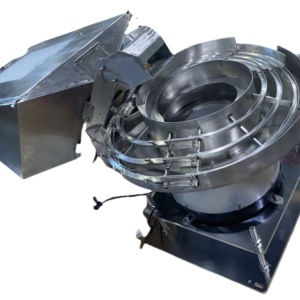

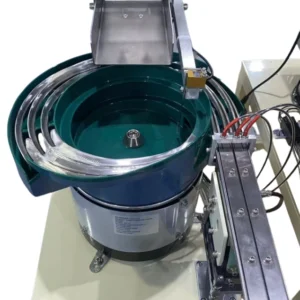

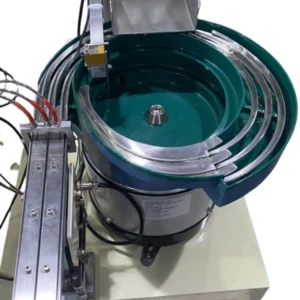

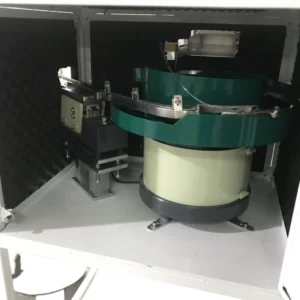

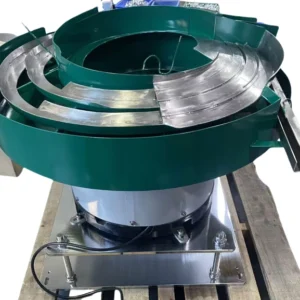

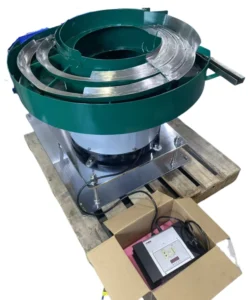

In industrial assembly automation, vibratory bowl feeders are widely used to feed components. These self-contained systems include a specially tooled bowl that orients the components, a vibrating drive unit on which the bowl is mounted, and a variable-amplitude control.

How does a bowl feeder work?

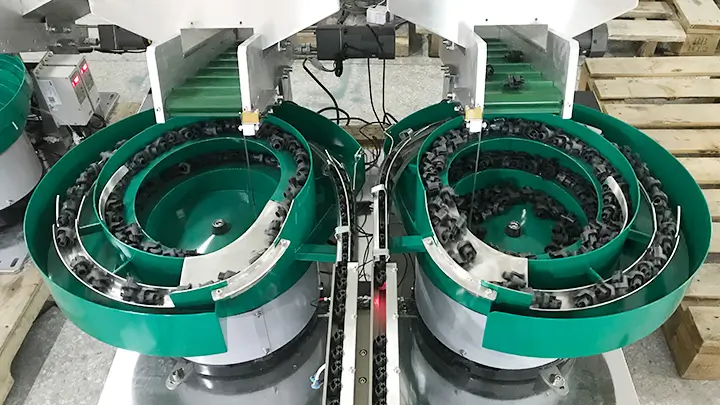

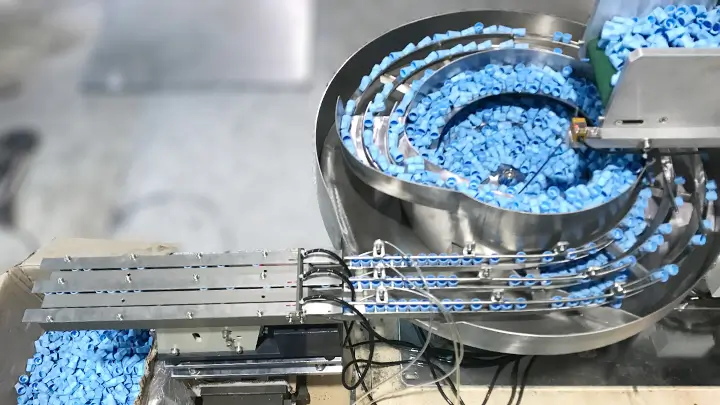

The bowl feeder and an out-feed accumulation track to convey parts and discharge them into the assembly machine come in various shapes and sizes. The drive unit, available in electromagnetic and pneumatic configurations, vibrates the bowl, causing the parts to move up a circular, inclined track. We design this track to sort and orient the parts into consistent, repeatable positions. By meticulously selecting the track’s length, width, and depth, we tailor it to suit the specific application, component size, and shape. Additionally, we apply special coatings based on the parts’ characteristics to improve traction, reduce product damage, and lower noise levels. A variable-speed control box manages the vibration of the bowl feeder, and sensors stop the flow of parts to the outfeed track as needed.

Applications of Bowl Feeders

Many industries widely use vibratory feeders, including pharmaceuticals, automotive, electronics, food, fast-moving consumer goods, packaging, and metalworking. They also serve industries such as glass, foundry, steel, construction, recycling, pulp and paper, and plastics.

These feeders offer a cost-effective alternative to manual labour, saving manufacturers time and labour costs. When you select a parts feeder, you need to consider several factors, including the industry, application, material properties, and product volume.

SWOER engineers and manufactures the most reliable and highest quality vibratory part feeding systems, providing low-maintenance and accurate handling solutions for a broad range of material parts processing applications.

Our experienced project managers oversee the entire production process for your application. If you are seeking a high-quality vibratory feeder or a special-purpose handling system, please do not hesitate to contact us by phone, email, or simply by using the inquiry form.

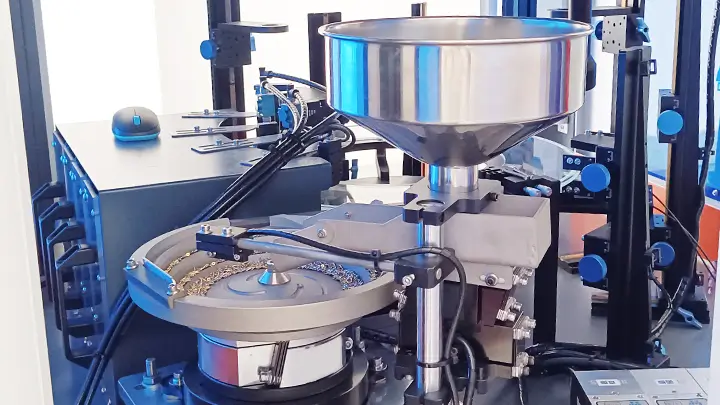

Bowl Feeders with Vision Inspection Integration and Glass Turntable Optical Inspection Sorting Machine

SWOER Automation offers complete feeding and handling solutions, including bowl feeders with vision inspection integration and glass turntable optical inspection sorting machine, to accurately position parts for collection by the customer’s handling units. Read More >>>