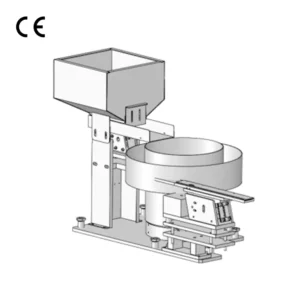

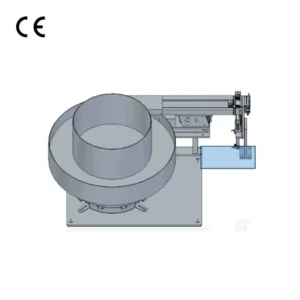

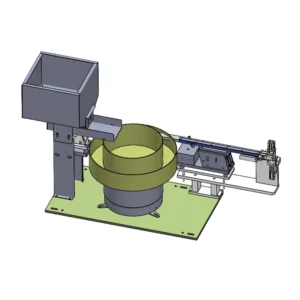

Advantages of the CCD system with vibro feeder:

Ultra high precision: achieving detection accuracy and stability that cannot be compared to the human eye.

100% online full inspection: Each part can be tested to ensure factory quality.

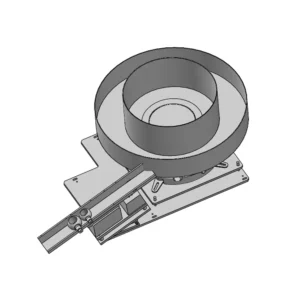

High flexibility: When the product is changed, it usually only needs to replace the vibration disk track and modify the visual software program, with strong adaptability.

Data recording: It can collect data such as production quantity, yield rate, and types of defective products, providing a basis for production management and process improvement.

Reducing overall costs: Although the initial investment is high, in the long run, it greatly saves labor costs, avoids quality risks and after-sales costs caused by missed inspections.

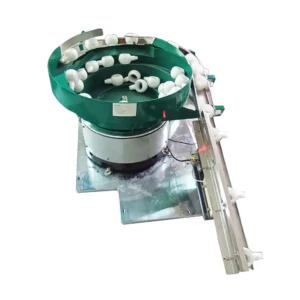

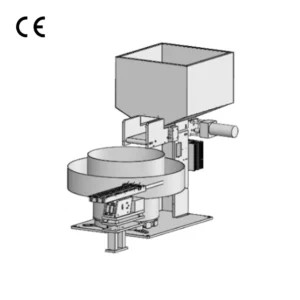

Examples of application scenarios

Electronics industry: Direction recognition and defect detection of mobile phone components such as screws and connectors.

Automotive industry: Dimensional measurement and visual inspection of precision small parts such as piston pins and sensor components.

Medical industry: Testing of syringe needles and surgical instrument components that require extremely high cleanliness and integrity.

Hardware industry: mixing and sorting of screws and nuts, and tooth profile testing.

Đánh giá

Hiện tại không có đánh giá nào.