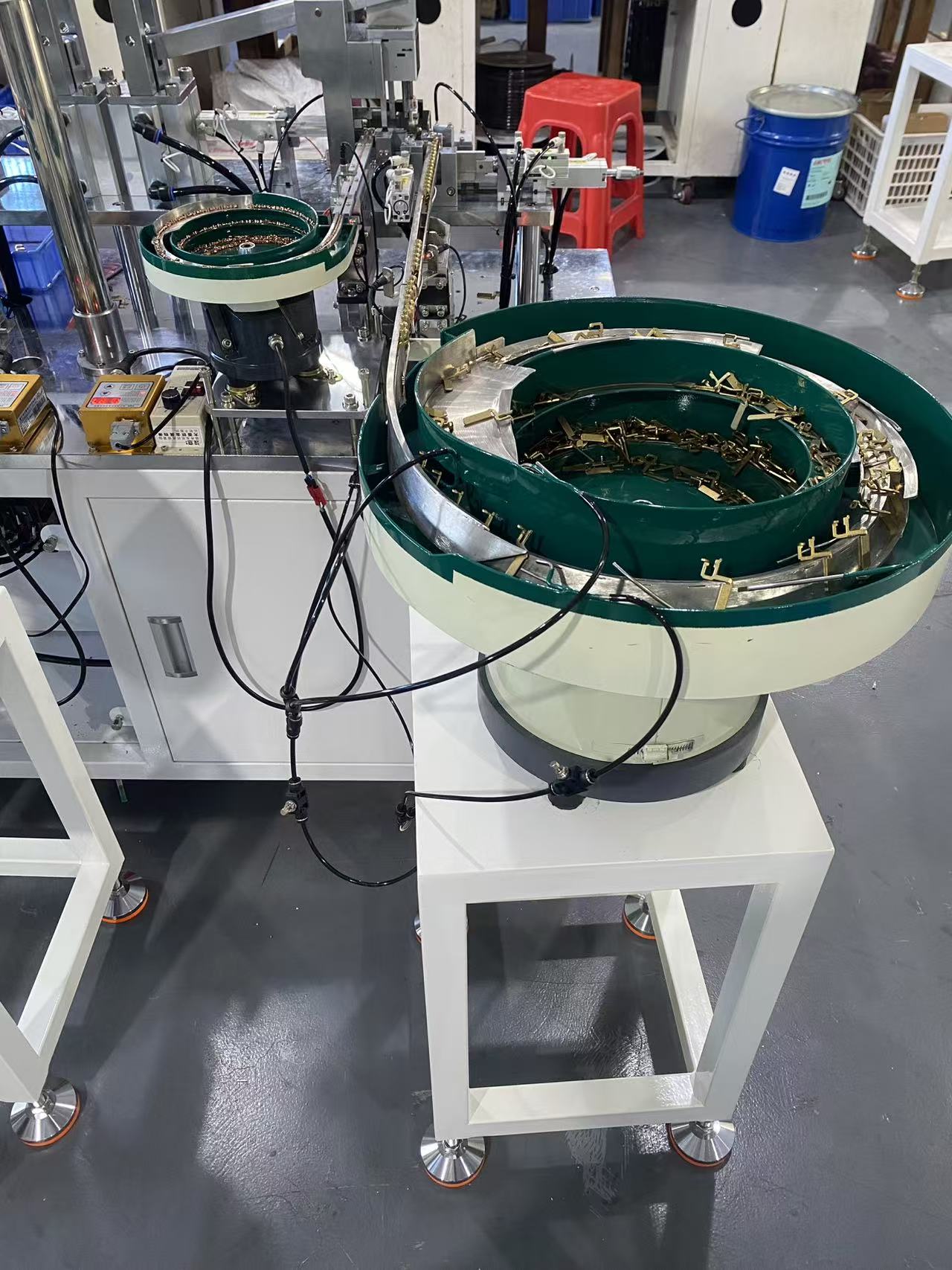

Benefits and Functions of Adding a Camera to a Vibratory Bowl

- Core Benefits

- Near-Perfect Orientation Accuracy

- Sự miêu tả: Vision systems can identify minute features, ensuring virtually every part is correctly oriented.

- Benefit: Eliminates downtime and defects caused by misoriented parts, significantly boosting first-pass yield.

- Integrated In-Line Quality Inspection

- Sự miêu tả: The camera inspects part quality while orienting.

- Benefit: Real-time rejection of parts with dimensional flaws, burrs, scratches, contamination, or missing features, controlling quality at the source.

- High Flexibility and Rapid Changeover

- Sự miêu tả: Product changeover requires only a software program change, not mechanical retooling.

- Benefit: Reduces changeover time from hours to minutes, ideal for high-mix, low-volume production.

- Provides Precise “Eyes” for Robots

- Sự miêu tả: The vision system calculates the part’s precise X, Y coordinates and rotation angle (θ).

- Benefit: Enables robots to perform high-precision, adaptive picking, solving the challenge of “blind” robot grasping.

- Core Functions

- Precise Positioning: Determines exact part location and orientation for downstream automation.

- Sorting and Screening: Separates acceptable parts from rejects based on predefined criteria.

- Data Traceability: Records production counts, yield, and defect types for process control.

In summary, adding a camera transforms a vibratory bowl from a mechanical sorter into an intelligent sensing and control node. Its core value lies in integrating precision, quality control, flexibility, and traceability—a key step towards advanced automated manufacturing.

Đánh giá

Hiện tại không có đánh giá nào.