Manufacturing Methods of Vibratory Bowls

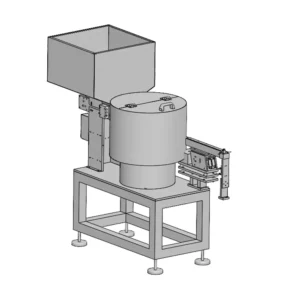

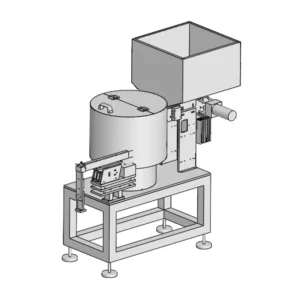

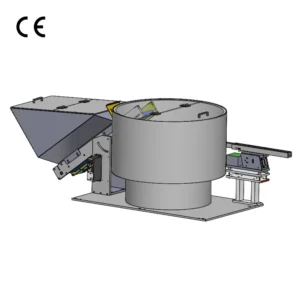

The manufacturing of a vibratory bowl is a specialized process that combines experience, precision machining, and tuning skills. It is far more than just making a “metal bowl” and involves several core stages:

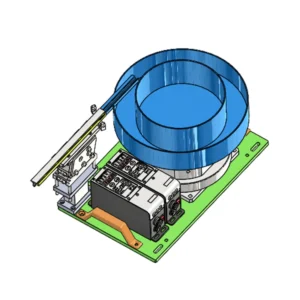

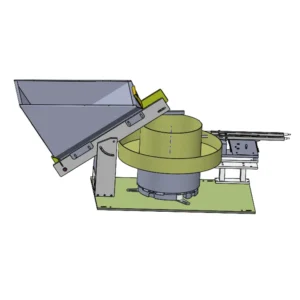

- Part Analysis and Solution Design

This is the most critical first step. Engineers must thoroughly analyze the target part.

- Analysis Includes: The part’s geometry, dimensions, material, weight, center of gravity, and the required final discharge orientation.

- Output: Based on the analysis, the spiral track layout inside the bowl is designed, and the necessary tooling for sorting, orienting, and correcting parts is determined.

- Bowl and Track Fabrication

- Material Selection: Stainless steel is primarily used due to its strength, corrosion resistance, and non-magnetic properties.

- Manufacturing Process:

- Blanking and Forming: The bowl plate is cut and rolled into a conical shape, then welded.

- Track Fabrication: The track is precisely bent, cut, and welded from stainless steel strips. It must be dimensionally accurate and smooth to prevent jams.

- Surface Treatment

The track and bowl surface are treated to control friction and prevent part damage.

- Non-stick Coatings: Reduce friction and static for delicate parts.

- Abrasive Finishing: Increases friction for light or smooth parts.

- Plating: Provides a hard, wear-resistant surface.

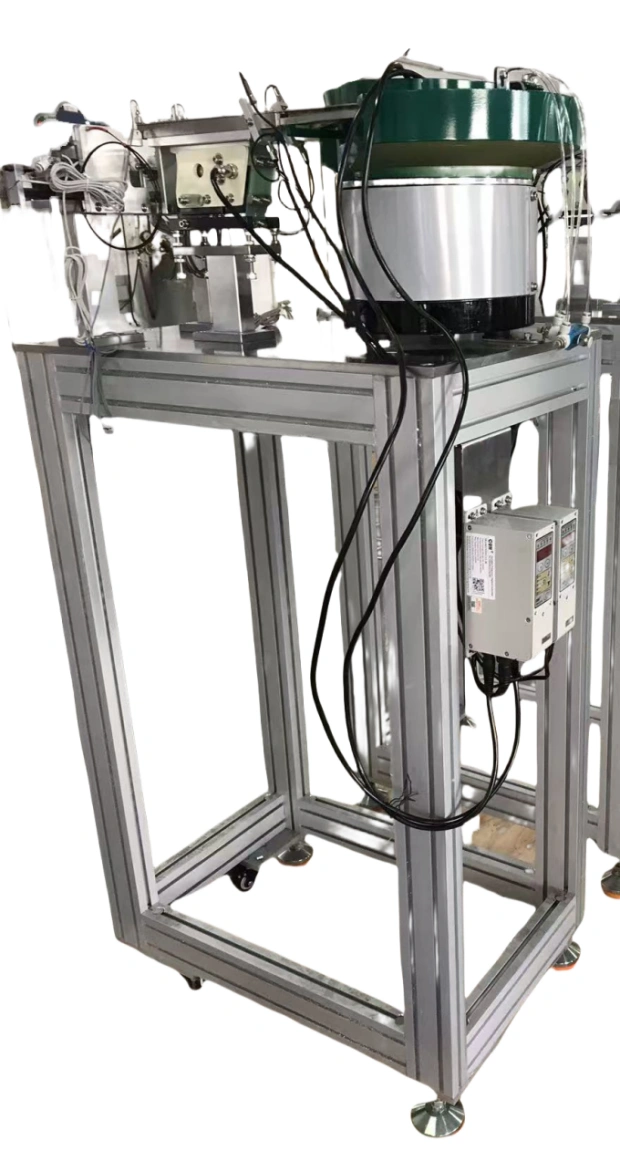

- Base and Drive Unit Assembly

- Base: Supports the bowl and houses the electromagnetic drive.

- Spring Leaf Assembly: Connects the bowl to the base; its angle and stiffness are critical for vibration.

- Electromagnet: The drive source that creates pulsed magnetic forces to vibrate the bowl.

- Bộ điều khiển: Điều chỉnh tần số và biên độ rung.

- Tuning and Testing

This is the “art” of transforming hardware into a functional system.

- Process: Actual parts are used to fine-tune the system by adjusting the spring angle and controller settings until parts feed smoothly and consistently.

- Endurance Testing: Long-term testing ensures reliability under production conditions.

In summary, manufacturing a vibratory bowl is a process that integrates mechanical design, materials science, and dynamic tuning, relying heavily on the experience and skill of the engineer.

Đánh giá

Hiện tại không có đánh giá nào.